Scroll to:

Justification of the rational scope and technology for the use of hydraulic excavators in surface mining

https://doi.org/10.17073/2500-0632-2025-09-460

Abstract

The constrained conditions of deep-pit mining and the rigid technological interdependence between operations on lower and upper horizons significantly complicate the performance of loading and haulage systems and, in particular, hinder the efficient use of large rope shovels. At the same time, due to a limited service life and a sharp decline in reliability after 7–10 years of operation, mobile hydraulic excavators cannot compete with mechanical shovels when excavating hard rock formations. Based on research and industrial experiments, combined solutions have been developed and tested for the use of rope and hydraulic excavators within their respective optimal application areas to improve the efficiency of mining operations. The proposed priority application zone for hydraulic excavators is defined in areas with a planned low concentration of drilling-and-blasting operations, where the utilisation factor of rope shovels is below 0.5, while that of mobile hydraulic excavators – with appropriate geomechanical support – is at least 0.7. At the same time, hydraulic excavators cannot directly compete with large mechanical shovels in the development of hard rock. Therefore, a specialised technology for within-block differentiation of drilling and blasting parameters is proposed to ensure the geomechanical conditions necessary for the effective integration of hydraulic excavators into mining operations.

Keywords

For citations:

Khakulov V.A., Shapovalov V.A., Ignatov V.N., Karpova Zh.V., Ignatov M.V., Nogerov I.A. Justification of the rational scope and technology for the use of hydraulic excavators in surface mining. Mining Science and Technology (Russia). 2025;10(4):338–345. https://doi.org/10.17073/2500-0632-2025-09-460

Justification of the rational scope and technology for the use of hydraulic excavators in surface mining

Introduction

As mining depth increases, the stripping ratio rises sharply, significantly reducing the profitability of open-pit operation [1–3]. The most effective way to partially stabilize stripping volumes with increasing depth [4, 5] is to maintain a relatively steep pit slope angle [6, 7]. However, two major factors limit this approach: the stability of pit walls and the sharp decline in productivity of loading and haulage systems employing large electric rope shovels [8, 9]. To ensure high equipment productivity at deep pit levels while maintaining a low current stripping ratio, mining operations are conducted within working concentration zones that are moved vertically along the pit wall1 [10]. This technology, which uses relatively wide working benches in concentration zones, enables efficient loading of productive mining systems with blasted rock mass. At the same time, moving these zones vertically along the pit wall requires time-consuming conservation and deconservation procedures. Additional complications arise due to a rigid technological interdependence, whereby progress in lower levels depends on the advancement of upper-level operations. Under such constrained conditions, large electric rope shovels cannot be used efficiently, and mobile hydraulic excavators are employed instead. However, hydraulic excavators cannot directly compete with large mechanical shovels, particularly when excavating hard rock formations [11].

Although mobile, this type of equipment is less suited to harsh mining conditions and has a shorter service life, with reliability declining significantly after 7–10 years of operation. At the same time, amid general trends toward the use of higher-capacity mining equipment in deep open pits, certain operational zones emerge where mobile hydraulic excavators can be used effectively. Therefore, research aimed at defining the rational application areas and technologies for using hydraulic excavators at mining and processing plants remains highly relevant.

A number of approaches have been proposed to improve the efficiency of hydraulic excavator operation. P. Bules2 justified the optimal service life of key components and systems of hydraulic mining excavators to extend their operational lifespan. However, this assessment did not address the technological aspects of excavator operation or specific application conditions. Without technological adaptation, hydraulic excavators remain less suited for severe mining environments.

Another line of research focuses on improving mining technology. For example, E. V. Loginov proposed3 a method for controlling the operational stripping ratio when using backhoe-type hydraulic excavators in deepening mining systems. Replacing rope shovels with backhoe-type hydraulic excavators in deep pit levels allows for narrower working benches. As a result, steeper pit slope angles can be formed, which correspond to a 10% reduction in the operational stripping ratio.

Nevertheless, the stripping ratio inevitably increases with depth [12–14]. To maintain mining efficiency, combined use of rope shovels and hydraulic excavators is required, each operating within its optimal application range. It is also necessary to consider that hydraulic excavators are less suited for excavating hard rock formations. The bucket filling efficiency in such conditions is affected by the ratio between bucket width and capacity — a parameter significantly higher for hydraulic excavators than for rope shovels of equivalent capacity. Moreover, the kinematic design of backhoes provides a substantially lower digging force. When comparing front-shovel and backhoe configurations of hydraulic excavators, it should be noted that these types differ in crowding and breakout forces. For instance, models of mining hydraulic excavators manufactured by Komatsu Mining Germany (KMG) with a backhoe configuration have 20–30% lower crowding force and 8–22% lower breakout force4.

1 Bules P. Ensuring the reliability of hydraulic mining excavators during open-pit operations in Russia [Cand. Sci. (Tech.) dissertation]. Moscow: National University of Science and Technology MISIS; 2016..

2 Loginov E. V. Control of the operational stripping ratio when using backhoe-type hydraulic excavators in deepening mining systems [Cand. Sci. (Tech.) dissertation]. St. Petersburg: Saint Petersburg Mining University; 2018

3 Bules P. Ensuring the reliability of hydraulic mining excavators during open-pit operations in Russia [Cand. Sci. (Tech.) dissertation]. Moscow: National University of Science and Technology MISIS; 2016.

4 Bules P. Ensuring the reliability of hydraulic mining excavators during open-pit operations in Russia [Cand. Sci. (Tech.) dissertation]. Moscow: National University of Science and Technology MISIS; 2016.

Research aim and objectives

The aim of this study is to justify the rational scope and technology for the use of hydraulic excavators.

Research objectives:

- to adapt hydraulic excavators for operation in harsh hard-rock mining conditions;

- to define the optimal application areas of hydraulic excavators and improve their reliability and competitiveness compared to rope shovels.

The stated objectives are addressed by implementing continuous monitoring of the excavation process with a focus on geomechanical conditions. The resulting data are used to refine rock blastability zoning, adjust drilling-and-blasting designs and the selection of equipment, optimize preventive maintenance schedules.

Research methods included:

- comparative analysis (evaluating the efficiency of rope and hydraulic excavators);

- analytical modelling (parameter calculations);

- instrumental monitoring (accelerometers, gyroscopes, and GPS sensors for analysing excavation performance);

- field experiments (tests conducted at open pits in the Kabardino–Balkarian Republic and Rostov Region);

- remote sensing (drone-based aerial photography for analyzing rock mass structure);

- machine learning (developing an expert model for predicting borehole capacity based on drill cuttings characteristics).

The central premise of this study is that rope shovels, although less sensitive to geomechanical variability and designed for long service life, are not efficient in all operating contexts. The findings highlight the need for an integrated mining approach in which rope and hydraulic excavators complement each other within their respective optimal application zones. Since hydraulic excavators have a shorter service life and declining reliability over time, their effective use becomes less straightforward. Hard and abrasive rock formations require a higher level of geomechanical support for hydraulic machines. In many cases, the degree of fragmentation sufficient for productive operation of rope shovels proves inadequate for hydraulic backhoes. Thus, although hydraulic excavators are widely used in the construction industry, their effective deployment in large-scale mining requires system-level adaptation that integrates technical, operational, and geomechanical factors. Partial adaptation that focuses only on individual aspects cannot fully resolve the problem. Measures aimed solely at improving reliability—such as more frequent replacement of high-wear components—are ineffective if geomechanical influences are not taken into account. The spatial and temporal variability of the structural and strength properties of the rock mass governs the geomechanical loading on the equipment and, consequently, its wear, which evolves together with operating hours and failure statistics across the excavator fleet. Therefore, to improve mining efficiency on a systematic basis, it is necessary to monitor geomechanical conditions so as to provide information support for revising rock blastability zoning, adjusting mining technology and equipment selection, updating preventive maintenance schedules.

Main theoretical framework

The primary methodological challenge lies in distinguishing between the technological and geomechanical components of equipment productivity losses. This issue was addressed by the authors in earlier studies through the development of an intelligent excavation monitoring module incorporating an accelerometer, gyroscope, barometer, magnetometer, GPS receiver, and temperature sensor. The module, enclosed in a shock-resistant housing, is magnetically mounted at the junction between the excavator arm and bucket. In particular, the presence of an accelerometer in the measurement module enables recognition of the excavator’s primary and auxiliary operational cycles, as well as spatial and temporal tracking of bucket position, by analysing the projections of gravitational force along the coordinate axes. The hardware and methodology of excavation process monitoring were successfully tested at open pits in the Kabardino–Balkaria Republic and Rostov Region during 2019–2022 [15].

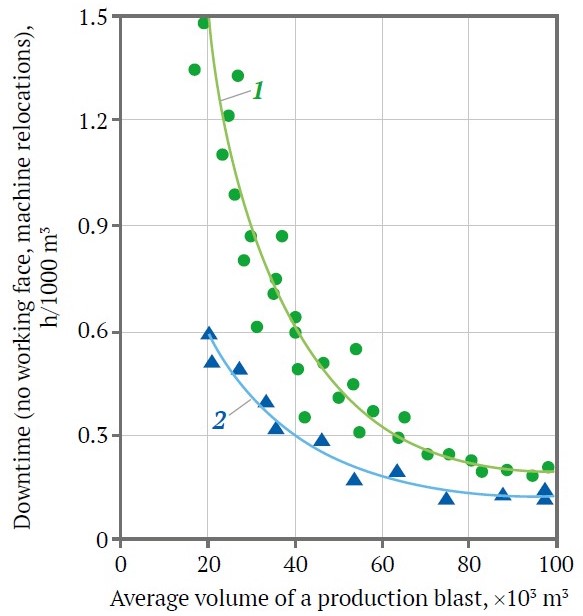

Fig. 1. Comparative analysis of the effect of concentrating drilling-and-blasting operations on downtime of rope and hydraulic excavators: 1, 2 – variation in operational downtime of rope shovel EKG-4.6 and hydraulic excavator Hyundai R520LC-9S associated with relocations and lack of blasted rock, respectively

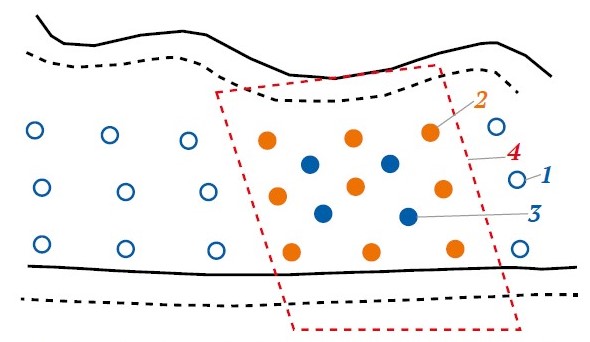

Fig. 2. Dependence of changes in borehole capacity on the structural properties of rock masses: 1 – fractured rock masses with closed joints; 2 – fractured rock masses with open or infill-filled joints; 3 – fractured rock masses with gaping (widely open) joints; 4 – boundary of controlled explosive fragmentation

Recording the spatial position of each operational cycle, along with changes in bucket filling time and volume, combined with the analysis of actual drilling-and-blasting parameters, provides insight into variations in the structural and strength properties of the rock mass. This technical solution enables excavation process monitoring with identification of the geomechanical component, allowing for refinement of rock blastability zoning, adjustment of mining technology and equipment selection, and optimisation of preventive maintenance schedules.

It is proposed that hydraulic excavators be used primarily in areas with a planned low concentration of drilling-and-blasting operations. As shown in Fig. 1, in zones of low blasting concentration, with production blast volumes of 20–40×10³ m³, the equipment utilisation factor falls below 0.5, indicating extremely low efficiency of rope shovels.

The proposed combined excavation technology for rope and hydraulic excavators is based on improving technological zoning according to rock blastability categories. The method involves, on one hand, concentrating blasting operations in areas suitable for high-efficiency operation of rope shovels, and on the other, designating zones for hydraulic excavators where concentrated blasting is technologically impractical or impossible.

The greatest challenges are posed by hard, abrasive rock masses, including those disturbed by both underground [16, 17] and surface mining operations, which require a higher level of geomechanical support for effective hydraulic excavator operation. When fragmentation meets the performance criteria for rope shovels but is insufficient for hydraulic backhoes, it becomes necessary to switch to smaller-diameter boreholes with a higher drilling volume. At the same time, it must be considered that fractured rock masses naturally break along joint planes during blasting, and additional explosive consumption does not improve fragmentation quality. For a meaningful comparative analysis of technologies using different drilling and loading equipment, the productivity of drilling rigs should be evaluated in terms of the mass of blasted rock.

Significant difficulties arise in fractured rock masses containing large-block inclusions, where both rock blastability and borehole capacity within a single blast block vary considerably. For example, in fractured rocks with gaping joints, the capacity of boreholes drilled with a 243 mm bit for granular explosives can exceed 59 kg/m, whereas in monolithic rocks this value is about 45–47 kg/m. Increased borehole capacity negatively affects charge column placement [18, 19], shifting it 15–20% downward within the borehole. As a result, the explosive charge becomes concentrated in the overdrilled section, leading to poor fragmentation in the upper part of the bench, disturbance of the floor of the underlying bench, and additional borehole losses due to induced fracturing.

To mitigate random downward displacement of the explosive column, zoning studies are conducted to determine the optimal parameters of drilling-and-blasting operations for fractured and blocky portions of the blast block and to clarify the relationship between borehole capacity and the structural properties of rock masses (Fig. 2). For different rock types, a characteristic particle-size class is defined – representing the lower limit of coarse drill cuttings, the yield of which reflects the blockiness of the rock mass. For example, the characteristic particle-size range for hornfels from the Tyrnyauz deposit is 5–10 mm.

Drilling plans are based on parameters relevant to the most fractured portions of a blast block (Fig. 3 – positions 1 and 2). After drilling the planned boreholes, the mass yield and particle-size distribution of the drill cuttings are used to localize poorly fragmentable zones. Boreholes drilled in such strong-rock portions of the massif exhibit smooth, non-sloughing walls and a sharply contrasting cuttings signature (a high yield of cuttings concentrated at the characteristic size). By contrast, boreholes drilled in the fractured parts of the block display irregular walls with spalls and gaping joints and produce a low yield of cuttings, the sizes of which substantially exceed the established characteristic values.

It should be noted that the effectiveness of this relatively simple technology strongly depends on the human factor. In particular, the heavy reliance on visual assessment of borehole condition adversely affects the accuracy of rock-type and blastability zoning and complicates subsequent verification and post-processing. To overcome this limitation, we propose recording the position and condition of borehole collars using an unmanned aerial vehicle to enable automated identification of prospective zones and differentiation of blasting parameters within a blast block (Fig. 4).

Fig. 3. Technological scheme for differentiating blasting parameters in areas of high variability in rock-mass structure: 1, 2 – boreholes drilled according to the block drilling plan (1 – identified by monitoring as drilled in fractured rock; 2 – identified by monitoring as drilled in massive/monolithic rock); 3 – additional boreholes drilled following corrective calculations; 4 – zone of large-block rock localization identified by monitoring.

Fig. 4. Drilled blast block imaged by unmanned aerial vehicle (UAV), with a zone highlighted as prospective for differentiated blasting parameters

The task of revising rock-mass zoning by blastability is addressed through monitoring supported by intelligent models and by system-level analysis of mining process outcomes, measured parameters and industrial blast indicators tied to the specific rock-mass location under study.

The proposed technology for areas with elevated structural variability in the rock mass is implemented in two stages:

- at the first stage, drilling is carried out according to the design using parameters relevant for the most fractured part of the block;

- at the second stage, within the localized hard-to-blast zones, one or two additional blast holes are drilled at the centre of each group of four previously drilled holes.

Methodology for calculating drilling and blasting parameters

An increased consumption of explosives required for breaking strong rock masses necessitates additional drilling, the total length of which is determined by the following expression, m [18]:

Lad = (qex − qr)Vs/(Pku), (1)

where qex – specific explosive consumption required for breaking the block’s coarse-fragmented zone, kg/m³; qr – specific explosive consumption according to zoning data for the fractured part of the block, kg/m; Vs – volume of the strong-rock portion of the block, m³; ku – borehole utilisation factor, dimensionless; P – borehole capacity in the coarse-block portion of the block, determined by the following expression, kg/m [18]:

P = k1 + k2Vct/Cch, (2)

where k1 and k2 – proportionality coefficients specific to the rock type; Vct – yield of drill cuttings from boreholes drilled in strong-rock zones, %; Cch – content of the most characteristic particle-size classes in drill fines, %.

To scale up the technology of within-block differentiation of drilling and blasting parameters, preliminary studies must be conducted for various rock types to establish correlations between the characteristics of drill cuttings and the capacity of drilled boreholes. The most labour-intensive operations involve determining such parameters as drill cuttings yield, content of the characteristic particle-size classes, and actual borehole capacity for each block.

It should be noted that reliable prediction of borehole capacity is essential for efficient blast design. To improve reliability and responsiveness, a machine learning–based method has been developed. The model’s database includes high-resolution images of block boreholes and experimentally obtained borehole capacities measured during charging. Model training necessarily involves comparing predicted and actual values, followed by testing on data from the next block.. A technology has been developed for drone-based imaging and laser scanning of the block, providing information support for a self-improving clustering model that predicts borehole capacity based on the characteristics of drill cuttings. This approach resolves the most labour-intensive component in implementing the within-block differentiation of drilling and blasting parameters.

Conclusion

Based on the conducted research and industrial experiments, combined solutions have been developed and tested for the use of rope and hydraulic excavators within their respective optimal application areas to improve the efficiency of mining operations. The priority application zone for hydraulic excavators is defined as areas with a planned low concentration of drilling-and-blasting operations, where the utilisation factor of rope shovels is below 0.5, while that of mobile hydraulic excavators is at least 0.7. At the same time, hydraulic excavators cannot directly compete with large mechanical shovels, particularly when working in hard rock formations. To address this issue, a specialised technology for within-block differentiation of drilling and blasting parameters is proposed, providing the geomechanical conditions necessary for the effective integration of hydraulic excavators into large-scale mining operations.

References

1. Blom M., Pearce A. R., Stuckey P. J. Short-term planning for open pit mines: a review. International Journal of Mining, Reclamation and Environment. 2019;33(5):318–339.https://doi.org/10.1080/17480930.2018.1448248

2. Nehring M., Knights P. F., Kizil M. S., Hay E. A comparison of strategic mine planning approaches for in-pit crushing and conveying, and truck/shovel systems. International Journal of Mining Science and Technology. 2018;28(2):205–214. https://doi.org/10.1016/j.ijmst.2017.12.026

3. Anistratov K. Yu. Feasibility Study of the Efficiency of Using EKG-18 Rack-and-Pinion Crowd Mining Excavators Manufactured by PJSC "Uralmashplant" in Coal Open-Pit Mines. Russian Mining Industry. 2016;(5):18–23. (In Russ.)

4. Demirel N., Taghizadeh A., Khouri S., Tyuleneva E. Optimization of the excavator-and-dump truck complex at open pit mines–the case study. In: IIIrd International Innovative Mining Symposium. E3S Web of Conferences. 2018;41:01006. https://doi.org/10.1051/e3sconf/20184101006

5. Kuznetsov D., Kosolapov A. Dynamic of performance of open-pit dump trucks in ore mining in severe climatic environment. Transportation Research Procedia. 2022;63:1042–1048. https://doi.org/10.1016/j.trpro.2022.06.104

6. Makarov V. N., Anistratov K. Yu. Achievement of the highest record indicators of the monthly production of EKG-18 excavators at open-pit mines of “Stroyservice” JSC. Ugol’. 2019;(1):20–26. (In Russ.) http://dx.doi.org/10.18796/0041-5790-2019-1-20-26

7. Upadhyay S. P., Askari-Nasab H. Simulation and optimization approach for uncertainty-based short-term planning in open pit mines. International Journal of Mining Science and Technology. 2018;28(2):153–166. https://doi.org/10.1016/j.ijmst.2017.12.003

8. Deryabin S. A., Rzazade U. A. O., Kondratev E. I., Temkin I. O. Metamodel of autonomous control architecture for transport process flows in open pit mines. Mining Informational and Analytical Bulletin. 2022;(3):117–129. (In Russ.) https://doi.org/10.25018/0236_1493_2022_3_0_117

9. Samavati M., Essam D., Nehring M., Sarkeret R. A local branching heuristic for the open pit mine production scheduling problem. European Journal of Operational Research. 2017;257(1):261–271. https://doi.org/10.1016/j.ejor.2016.07.004

10. Samavati M., Essam D., Nehring M., Sarkeret R. A new methodology for the open-pit mine production scheduling problem. Omega. 2018;81:169–182. https://doi.org/10.1016/j.omega.2017.10.008

11. Khakulov V. A., Shapovalov V. A., Ignatov V. N. et al. Rational technology and application domain of hydraulic backhoes in open pit mines. Mining Informational and Analytical Bulletin. 2023;(8):112–127. (In Russ.) https://doi.org/10.25018/0236_1493_2023_8_0_112

12. Moreno E., Rezakhah M., Newman A., Ferreira F. Linear models for stockpiling in open-pit mine production scheduling problems. European Journal of Operational Research. 2017;260(1):212–221. https://doi.org/10.1016/j.ejor.2016.12.014

13. Rais K., Kara M., Gadri L. et al. Original approach for the drilling process optimization in open cast mines; case study of Kef Essenoun open pit mine Northeast of Algeria. Mining Science. 2017;24:147−159. https://doi.org/10.5277/msc172409

14. Brown C. Autonomous vehicle technology in mining. World of Mining Professionals. 2012;(1):30–32.

15. Khakulov V. A., Shapovalov V. A., Ignatov V. N. et al. Improvement of geotechnology based on monitoring and zoning of the geomechanical state of rock massifs. Mining Informational and Analytical Bulletin. 2023;(9):68–83. (In Russ.) https://doi.org/10.25018/0236_1493_2023_5_1_20

16. Lyashenko V. I., Khomenko O. E., Golik V. I. Friendly and resource-saving methods of underground ore mining in disturbed rock masses. Mining Science and Technology (Russia). 2020;5(2):104–118. https://doi.org/10.17073/2500-0632-2020-2-104-118

17. Golik V., Komashchenko V., Morkun V., Irina G. Improving the effectiveness of explosive breaking on the bade of new methods of borehole charges initiation in quarries. Metallurgical and Mining Industry. 2015;7(7):383–387.

18. Zhaboev M. N., Khakulov V. A., Bakharev L. V., Ravikovich B. S. Improvement of the blasting technology for complex-structured rock masses. Gornyi Zhurnal. 1990;(9):22–23. (In Russ.)

19. Khakulov V. A., Karpova Zh. V., Khatukhova D. V., Shinakhova A. E. Improving drilling and blasting design based on artificial intelligence expert systems. Gornyi Zhurnal. 2025;(2):13–18. (In Russ.) https://doi.org/10.17580/gzh.2025.02.07

About the Authors

V. A. KhakulovRussian Federation

Viktor A. Hakulov – Dr. Sci. (Eng.), Head of the Department of Information Technologies in Control of Technical Systems

Nalchik

Scopus ID 57200144748

ResearcherID B-2340-2018

V. A. Shapovalov

Russian Federation

Vitaliy A. Shapovalov – Dr. Sci. (Eng.), Professor of the Department of Information Technologies in Control of Technical Systems

Nalchik

Scopus ID 57190966150

ResearcherID J-9696-2015

V. N. Ignatov

Russian Federation

Viktor N. Ignatov – Dr. Sci. (Eng.), Professor of the Department of Mining

Novocherkassk

Scopus ID 57200148638

Zh. V. Karpova

Russian Federation

Zhanna V. Karpova – Cand. Sci. (Eng.), Engineer

Novocherkassk

Scopus ID 57204943495

M. V. Ignatov

Russian Federation

Mikhail V. Ignatov – Cand. Sci. (Eng.), Associate Professor of the Department of Information Technologies in Control of Technical Systems

Nalchik

Scopus ID 57204758591

I. A. Nogerov

Russian Federation

Ibragim A. Nogerov – Senior Lecturer of the Department of Information Technologies in Control of Technical Systems

Nalchik

Scopus ID 57200193883

Review

For citations:

Khakulov V.A., Shapovalov V.A., Ignatov V.N., Karpova Zh.V., Ignatov M.V., Nogerov I.A. Justification of the rational scope and technology for the use of hydraulic excavators in surface mining. Mining Science and Technology (Russia). 2025;10(4):338–345. https://doi.org/10.17073/2500-0632-2025-09-460