Scroll to:

Integration of digital technologies into the design process of power supply systems for mining enterprises

https://doi.org/10.17073/2500-0632-2025-09-461

Abstract

The study focuses on the development of an integrated software solution for the automation of power supply system (PSS) design for industrial enterprises. The relevance of this work arises from systemic issues observed in existing software packages, such as fragmented design processes, the need for repeated manual data transfer between different platforms, dependence on specific manufacturers’ equipment, and the lack of universal component selection tools. The research included a comprehensive analysis of current approaches to PSS design, the development of new automation methods, and the creation of algorithms for calculating electrical loads and selecting equipment. The methodological framework was based on regulatory standards and the principles of modular architecture, implemented in C# with integration into BIM platforms (nanoCAD) and spreadsheet processors (Excel). The key result is the creation of digital software that automates data collection from BIM models, calculation of electrical loads and short-circuit currents, and selection of PSS components. Practical testing on the power supply project of the Kumroch gold processing plant demonstrated an 80% reduction in manual operations, improved calculation accuracy, and independence from specific equipment manufacturers. The developed software solution effectively eliminates the main shortcomings of existing analogues by providing an end-to-end automated design process, which significantly enhances the efficiency, accuracy, and flexibility of design activities in the context of power sector digitalization.

Keywords

For citations:

Petrov V.L., Burmatova E.K., Pichuev A.V. Integration of digital technologies into the design process of power supply systems for mining enterprises. Mining Science and Technology (Russia). 2025;10(4):393–403. https://doi.org/10.17073/2500-0632-2025-09-461

Integration of digital technologies into the design process of power supply systems for mining enterprises

Introduction

The electrical systems of mining enterprises are subject to specific requirements determined not only by the need to ensure efficiency and safety but also by the complexity of technological processes involved in the extraction and processing of mineral resources [1]. The key requirements include reliability, stability, safety, electric power quality, cost efficiency, ease of operation, and flexibility for modernization. However, the design of power supply systems (PSS) that meet these criteria involves addressing a set of unique challenges that have no universal solutions. This is primarily due to a combination of factors such as the diversity of mining technologies, variability of technological chains, as well as the geological and geographical uniqueness of deposits, which collectively preclude the possibility of creating invariant design approaches [2–4]. Therefore, the formalization of new design methodologies that can adapt to the specifics of a particular facility while integrating modern digital tools represents a relevant scientific and practical task.

Modern digital technologies for designing power supply systems of industrial facilities comprise a set of specialized programs within software packages that employ computer-based methods for creating, modifying, analyzing, and optimizing design solutions. This enables the development of more accurate PSS models, improves collaboration between design participants, and provides the possibility of visualizing projects.

Digital design technologies employ specialized programs, including BIM platforms (Revit, nanoCAD BIM, ArchiCAD), computer-aided design (CAD) systems (AutoCAD, nanoCAD, SketchUp), and visualization tools (Lumion, V-Ray), among others1.

To identify the key features, strengths, and weaknesses of power supply system design processes at industrial enterprises, to substantiate the relevance of this topic, and to assess the degree of its development, an analysis of current research [5–7] was conducted. These studies reflect the main approaches to the automation of engineering calculations in PSS design [7–9] and were evaluated according to the following criteria:

- relevance to the project topic (load calculation, equipment selection, CAD integration) [7];

- practical orientation (tools used, architecture, programming languages) [8‒10];

- regulatory compliance (adherence to GOST, PUE, and SP standards);

- application of modern technologies (BIM, integration with Excel and nanoCAD) [11‒13].

The analyzed publications cover a wide range of solutions-from highly specialized calculation programs for 6–10 kV networks to BIM-integrated general design platforms. Most of them focus on improving the accuracy and speed of engineering calculations through the automation and formalization of methods regulated by industry standards [14‒16].

The main directions of development in digitalization, improvement, and practical implementation of software integrating digital technologies into the design of electrical systems for industrial enterprises include the following [17‒19]:

- Automation of electrical load and short-circuit current calculations. This functionality is fundamental to almost all analyzed systems. In many cases, it is implemented in environments that allow straightforward integration with Excel or other tabular formats2 [18, 19].

- Equipment selection (cables, circuit breakers, transformers). Approaches vary-from manual selection using tabulated data to semi-automated modules tied to specific manufacturers’ product lines. Universal and vendor-independent solutions remain scarce.

- Development of interfaces and interoperability assurance. Significant attention is paid to ensuring compatibility with alternative environments, particularly nanoCAD. Some projects implement data exchange through Excel (as a universal format), while others use BIM platform APIs. Ease of use and accessibility of the interface are crucial factors determining practical applicability.

- Modular architecture and scalability. The most advanced systems are built on the principle of expandable modules, allowing new functions to be introduced gradually and adapted to client-specific requirements.

- Software development considering the evolution of programming languages. Both outdated environments (e.g., C++ with Access) and modern C#-based approaches are found. A noticeable gap exists between academic developments and commercial solutions: the former are often cumbersome and difficult to implement, whereas the latter tend to be proprietary and brand-dependent.

Studies consistently demonstrate growing interest in automating design processes; however, most existing solutions exhibit several limitations:

- Many systems are tailored for use with components from specific brands (Schneider, Siemens, ABB, etc.), thus restricting their applicability in design organizations using products from multiple suppliers.

- Complex or overloaded interfaces. Some software packages, such as EPLAN, feature excessively intricate architectures requiring user training, whereas most engineers need to perform standard calculations quickly and without deep customization.

- Lack of an independent equipment selection module. In many cases, the selection of cables and equipment remains a manual or semi-automated process relying on limited databases. The project developed within this research aims to implement automated selection based on generalized parameters, improving flexibility and accuracy.

- Weak integration with BIM environments. Despite the widespread adoption of BIM modeling tools in engineering practice, only a few solutions support direct integration. The proposed software enables Excel-based data export from nanoCAD, simplifying linkage between calculations and BIM models.

- Limited dissemination of open solutions. Academic developments often do not progress to a fully functional prototype, lack documentation, and cannot be scaled.

Despite recent technological advances, current PSS design workflows at industrial and mining enterprises still include processes that require extensive, repetitive manual work. This issue primarily arises from the need to repeatedly transfer identical data between different software environments, often multiple times, since design inherently involves numerous revisions and iterations. These stages not only increase labor intensity and time consumption but also introduce a high probability of human error due to monotony and data volume.

Most existing software packages are produced by electrical equipment manufacturers, which compromises calculation objectivity and ties users to specific brands. Meanwhile, client companies typically maintain approved brand lists, requiring designers to use components from particular suppliers.

Analogous programs often have complex structures and unintuitive interfaces, demanding excessive time and effort to master.

Digitalization offers broad opportunities for implementing innovative solutions and optimizing the design process itself. This enables more accurate calculations, reduces the number of errors, and enhances overall project efficiency-particularly important under conditions where construction speed and resource optimization are critical.

Digital design technologies for PSS not only improve project quality but also significantly influence overall project budgets. The implementation of automated systems and software can reduce the time required for design development by up to 30%.

Moreover, the reduction in errors and rework achieved through precise calculations and modeling decreases the risk of additional costs, leaving more flexibility within the approved budget and creating room for the adoption of even more effective technological solutions.

A promising direction for introducing digital technologies into PSS design for industrial enterprises involves combining artificial intelligence and big data to enable real-time project adjustments and integration with renewable energy sources-such as solar panels and wind turbines-for more efficient use of sustainable energy.

1 Electrical design: digital technologies and their role in modern construction. Energy-Systems. Energy-systems: Russian BIM technologies: designing power supply systems in Model Studio CS. Habr. URL: https://habr.com/ru/companies/nanosoft/articles/581434/

2 RTM 36.18.32.4–92 Guidelines for Electrical Load Calculation. VNIPI Tyazhelectroproekt; 1992.

Research objectives and tasks

The objective of this study is to develop architectural and methodological solutions for integrating digital technologies into the design process of electrical systems at mining enterprises by adapting software for calculating electrical loads and selecting power supply system components.

The main research methods include: comparative analysis, used to assess the functionality and limitations of modern software packages (BIM platforms, CAD systems, and calculation tools); mathematical modeling, applied for developing algorithms to calculate loads and short-circuit currents according to regulatory methodologies; algorithm design and programming, involving the creation of modular software in C# to automate calculations, equipment selection, and two-way integration with Excel and nanoCAD platforms; experimental testing, based on validating the software using real data from the power supply project of the Kumroch gold processing plant; systems approach, aimed at optimizing the design workflow as a unified cycle that eliminates manual operations and integrates all stages.

During the software development process, the following tasks must be accomplished.

- Identify systemic problems, limitations, and evaluate the functionality of existing software packages.

- Formalize and algorithmize the methodology for calculating electrical loads and short-circuit currents in accordance with regulatory standards, and develop algorithms for selecting PSS components.

- Implement an integrated software package in C# that automates calculations, equipment selection, and two-way data exchange with nanoCAD and Excel platforms to eliminate manual data transfer.

- Test software modules using real data from a mining enterprise power supply project.

The expected outcome is a software package capable of performing load calculations and automatically selecting optimal equipment parameters based on Excel input data, taking into account electrical loads, short-circuit currents, and the overall configuration of the power supply system.

The product is intended for use by mining companies during the design or technical upgrading stages. Potential users include design organizations involved in developing PSSs for mining enterprises.

Architecture of the PSS design framework

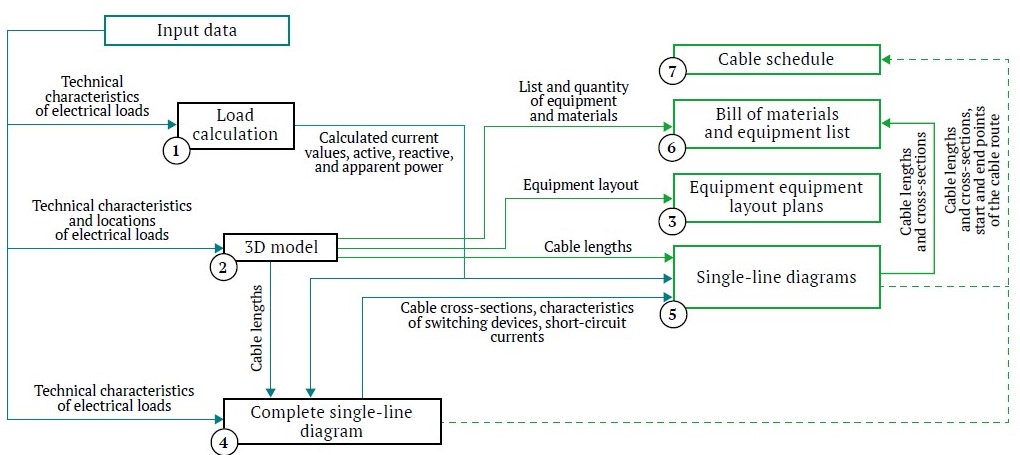

The design process can be illustrated using the schematic shown in Fig. 1.

Input data are typically provided as a list of electrical loads, specifying their type, rated electrical (or mechanical) power, rated supply voltage, efficiency, power factor, operating mode, control location, power supply reliability category as defined by the Electrical Installation Code (PUE), annual operating hours, and location.

At Stage 1, the technical characteristics are used to calculate electrical loads. The calculation is performed in Microsoft Excel using the method of maximum demand and utilization factors. Although the use of software automates the computational part, human input is still required: first, to manually assign electrical loads to distribution boards; and second, to select the maximum demand factor from reference tables based on the utilization factor and the effective number of electrical loads.

At Stage 2, using the initial data, electrical loads are manually added to the 3D model of the production facility created in the BIM platform. Each electrical load is then manually assigned to its power source in the model. Cable routes are generated automatically, but in some cases they require manual adjustment.

At Stage 3, equipment layout plans are prepared. This step is semi-automated: the designer defines section ranges to display each part of the production facility on separate drawings.

At Stage 4, the input data are used to create the complete single-line diagram of the power supply system. The diagram is manually assembled from individual elements (electrical loads, cable lines, bus sections, switching devices, etc.). The technical parameters of the loads and the cable lengths calculated at Stage 2 are entered manually, while the coefficients are adjusted so that the calculated values correspond to those obtained during the load calculation at Stage 1.

Fig. 1. Structural diagram of the current PSS design workflow

At Stage 5, single-line diagrams are prepared for each distribution board. Cable lengths from the board to each electrical load are automatically inserted into the diagrams based on the equipment arrangement in the model. The software also automatically selects cable cross-sections and the rated currents of circuit breakers. Unfortunately, many software packages do not display short-circuit current calculation results to the user, which forces designers either to use alternative tools for cable and switchgear selection or to perform these calculations manually. In the current workflow, this is done at Stage 4. The parameters of the devices and the cable cross-sections are then entered into the diagrams manually. For each distribution board, the parameters calculated at Stage 1-active, reactive, and apparent power, design current, power factor, and utilization factor-are added.

At Stage 6, a bill of materials and equipment list are generated using built-in BIM-platform functions.

At Stage 7, a cable schedule is compiled within the BIM platform.

Thus, the existing design workflow requires repeatedly performing identical, monotonous operations to transfer information between different software environments and reconcile data between them. This not only complicates the designer’s work and increases labor and time costs, but also introduces numerous errors caused by the human factor.

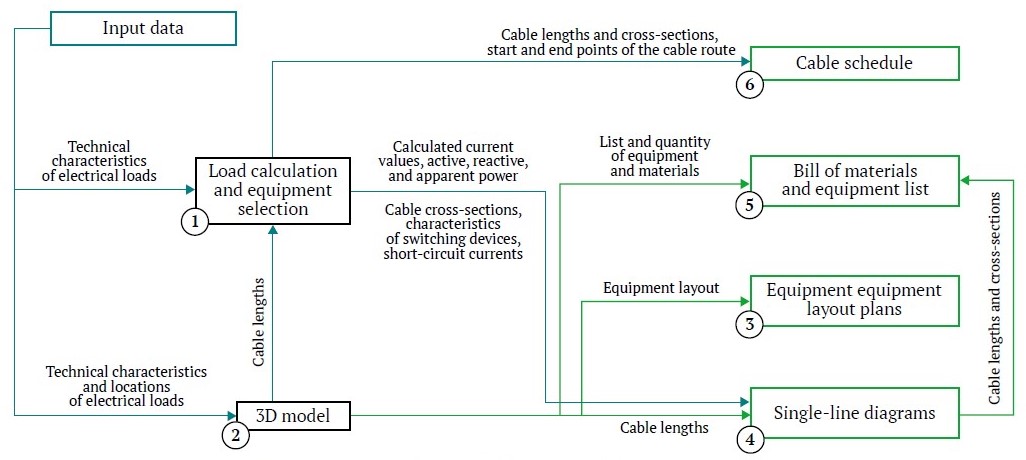

This workflow clearly requires optimization. The analysis shows that one of the most effective simplifications is to combine Stages 1 and 4 using an external software module. The corresponding design workflow is shown schematically in Fig. 2.

Fig. 2. Structural diagram of the optimized PSS design workflow

Key changes:

- Stages 1 and 4 of the original workflow are eliminated through automation;

- data are exchanged between Excel and the BIM platform automatically, without manual intervention;

- load calculation, short-circuit current analysis, and equipment selection are integrated into a single computational algorithm.

Such optimization significantly reduces manual work, streamlines the design workflow, and minimizes the risk of data transfer errors when processing large volumes of project information.

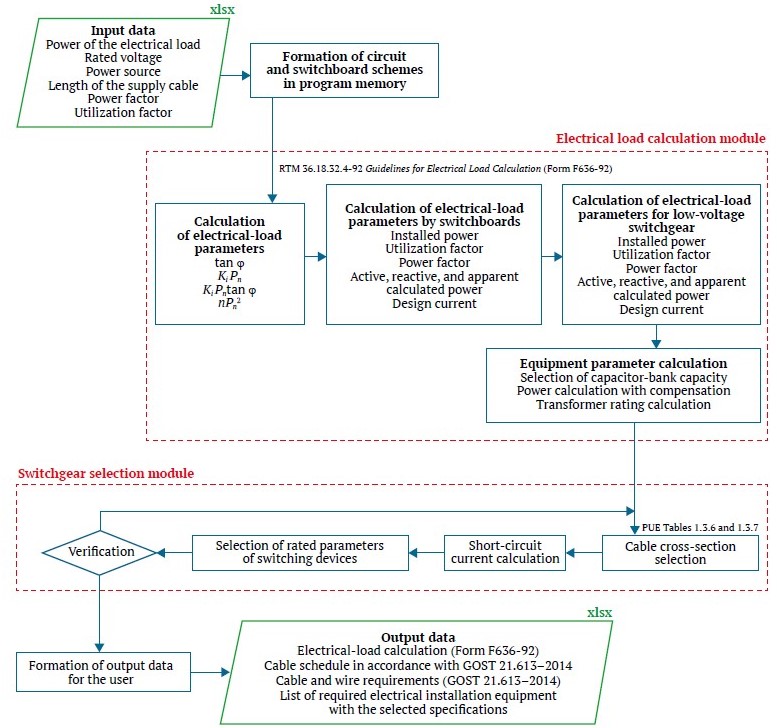

The technological process implemented in the software is illustrated in Fig. 3.

The block diagram represents the program structure designed to automate electrical load calculation and equipment selection in accordance with regulatory requirements. It integrates the stages of data input, parameter calculation, equipment selection, and report generation, meeting the research objective of reducing manual operations, improving accuracy, and ensuring interoperability with existing engineering tools.

The input data for the program are stored in an Excel spreadsheet that includes the electrical parameters of the loads, the power source, and the length of the supply cable. These data are automatically imported from the BIM platform.

The electrical load calculation module performs computations in accordance with the regulatory methodology RTM 36.18.32.4-92, taking into account load grouping (individual consumers, low-voltage switchboards, and distribution panels), calculation coefficients, power types (active, reactive, apparent), and current values. At this stage, the program also determines the required capacity of reactive power compensation devices and selects transformer ratings.

The next module is responsible for equipment selection. Based on the calculated data and short-circuit current values, the program determines cable cross-sections according to the PUE tables and selects the rated parameters of protective and switching devices. All results are automatically verified for compliance with specified parameters, after which the output data are generated.

The output data, presented in Excel format, include: electrical load calculations in accordance with Form F636-92; cable schedule compliant with GOST 21.613-2014; cable and wire specifications as per GOST 21.613-2014; a bill of materials and equipment list with the selected specifications.

Fig. 3. General block diagram of the calculation algorithm

The software is developed in C#, a programming language offering broad capabilities for engineering applications, including efficient tabular data processing (particularly Excel), convenient interface design tools, and native integration with the Windows environment, which is standard in engineering practice. C# provides high calculation reliability through strict typing and compile-time verification, while supporting modular architecture suitable for scalable functional expansion. These advantages make it an optimal choice for developing digital software (DS) for PSS design automation and equipment selection.

The choice of Excel and nanoCAD is driven by both technological and practical considerations related to the requirements of modern engineering and CAD environments. Excel serves as the primary tool for data entry, storage, and structuring, providing a universal, flexible, and widely accepted tabular format that easily adapts to various design stages. Its built-in data processing functions enable two-way communication between the calculation module and the engineering model, eliminating manual data transfer and reducing the risk of errors.

The nanoCAD platform functions as a BIM-modeling environment, meeting the requirements of modern design organizations and supporting an end-to-end information model of a building or industrial facility. Its capacity to store geometric and parametric data on equipment, cable routing, and connection points makes it indispensable for the comprehensive design of electrical networks within an integrated construction model. Furthermore, the availability of an open API ensures integration with external calculation algorithms and enables the automation of processes such as cable routing, specification generation, and single-line diagram creation. Thus, the combination of Excel and nanoCAD ensures effective linkage between analytical and graphical design components, reduces routine operations, enhances the accuracy of engineering solutions, and ensures compliance with regulatory documentation.

Accordingly, the presented DS provides a unified design algorithm that encompasses all key stages-from data input to the generation of calculated and technical characteristics of the equipment. It automates repetitive operations, minimizes the human factor, and ensures conformity with regulatory standards. Integrating this algorithm into the design workflow significantly simplifies the process of electrical network design, enhancing its accuracy, reliability, and efficiency.

Practical implementation: case study of a gold processing plant power supply project

Let us consider the practical implementation of the project using the example of the power supply system of the Kumroch gold processing plant (GPP). The main power source for the GPP facilities is an autonomous containerized diesel power plant (DPP) with a rated voltage of 6.3 kV and heat recovery systems.

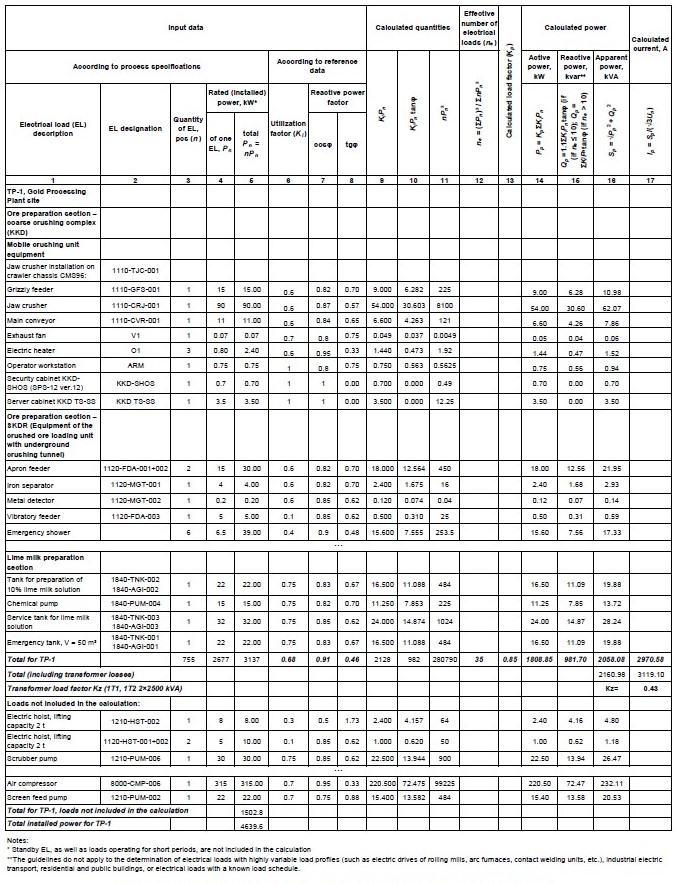

The digital software receives data on the formed circuits from the 3D model and generates load calculation tables for each distribution point at every level. A fragment of the electrical load calculation table for one of the transformer substations is shown in Fig. 4.

Fig. 4. Fragment of electrical load calculation for transformer substation 1 (TP-1)

The calculation is performed in accordance with the technical guideline Guidelines for Electrical Load Calculation RTM 36.18.32.4-92 [18], and its results are documented using the standard Form F636-923.

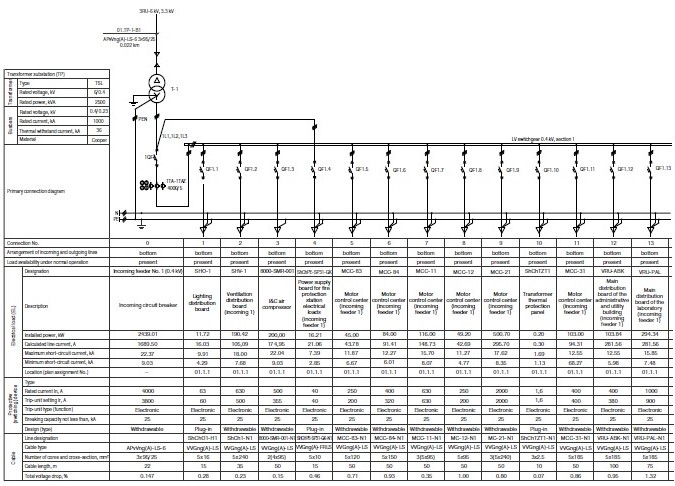

After the load calculation has been generated, the DS simultaneously performs short-circuit current calculations at all levels of the power supply system and selects the parameters of cable lines and switching devices, taking into account selectivity. This approach ensures high accuracy and speed of computations. The DS summarizes the calculation results in a table convenient for further use by the designer. Using the parameters calculated by the DS, the user can easily select equipment from the chosen manufacturer. A fragment of the equipment selection results is shown in the single-line diagram (Fig. 5).

Fig. 5. Fragment of the single-line electrical diagram of TP-1

Since the calculation in the program is performed automatically and requires virtually no additional actions from the designer, it is possible, if necessary, to repeatedly update the results with minimal labor input when the input data are revised. This increases the flexibility of the design process and adapts the DS to the conditions of continuous changes in system components during the development of power supply solutions.

Based on the results of the power supply system calculation for the Kumroch GPP, the authors in [20] evaluated the effectiveness of potential use of alternative power sources in autonomous power supply systems [21].

3 Table 4. Guiding Technical Material "Guidelines for the Calculation of Electrical Loads" of 30.07.1992 No. RTM 36.18.32.4-92. VNIPI TYAZHPROMELECTROPROJECT; 1992.

Conclusions

The developed (DS significantly reduces the number of manual data transfer operations-by up to 80%-while remaining independent of equipment manufacturers’ libraries. It requires minimal user involvement and does not demand specialized training to operate.

The DS automates the design process of power supply systems, simplifying and accelerating workflow operations, minimizing the likelihood of human error, and improving calculation accuracy. These features are essential for design organizations aiming to maintain client demand, remain competitive, and meet the current level of technological development.

Compared to existing software packages, the developed DS provides a more convenient format for input and output data in Excel tables, which minimizes manual data transfer. This, in turn, simplifies and accelerates work and enhances the precision of calculations.

Unlike similar programs, data reading is fully automated, and the DS requires minimal human intervention, which eliminates the need for additional training, ongoing technical support, or consultations.

Another advantage is that the developed DS is not tied to any specific electrical equipment manufacturer, enabling users to perform equipment selection independently while retaining full freedom of choice for designers and customers.

The solution has considerable potential for implementation in design organizations, as it aligns with the digitalization strategy of the energy sector and meets the market demand for flexible, independent, and scalable design tools.

Future development prospects involve the integration of artificial intelligence for real-time automatic project adjustments and the addition of calculation modules for alternative energy sources.

References

1. Pichuev A. V., Peturov V. I., Suvorov I. F. Impact of non-stationary modes on electrical safety during the operation of mining enterprises' electrical equipment. Monograph. Moscow: Gornaya Kniga; 2011. 326 p. (In Russ.)

2. Klyuev R. V. Development of a methodology for calculating swings in an electrical system. Sustainable Development of Mountain Territories. 2024;16(3):1205–1213. https://doi.org/10.21177/1998-4502-2024-16-3-1205-1213

3. Petrov V. L., Pichuev A. V. Assessing the efficiency of measures to enhance electric power quality in variable-frequency drive for scraper conveyors. Mining Science and Technology (Russia). 2024;9(1):60–69. https://doi.org/10.17073/2500-0632-2024-01-198

4. Klyuev R. V. Assessment of energy efficiency improvement strategies for ventilation and hoisting systems during the reconstruction of the Molibden mine. Mining Science and Technology (Russia). 2025;10(1):84–94. https://doi.org/10.17073/2500-0632-2024-10-362

5. Shemetov A. N., Ilina E. A., Kondrashova Yu. N. Information processing in the automated power supply system of a residential microdistress for determining electric loads. Software of Systems in The Industrial And Social Fields. 2021;9(2):29–37. (In Russ.) https://doi.org/10.18503/2306–2053-2021-9-2-29–38

6. Stepanov V. M., Kosyrikhin V. S. Application of the program-methodical complex for calculation and design of electrical supply. Izvestiya Tula State University. Technical Sciences. 2018;(12):180–186. (In Russ.)

7. Lyashan I. K., Parfenov Ya. A., Golovanova K. A. Design of internal power supply scheme. Vestnik Nauki. 2024;3(3):614–622. (In Russ.)

8. Dmitriev A. A., Gerasimov V. E., Ploskov A. N. Application of modern software capabilities in the design of power supply systems. Electrical and Data Processing Facilities and Systems. 2019;15(1):20–25. (In Russ.) https://doi.org/10.17122/1999-5458-2019-15-1-20-25

9. Klochkova N. N., Obukhova A. V. Automation of design of 6-10 kV power supply systems for industrial facilities. Nauchnyi Almanakh. 2024;(7–2):49–51. (In Russ.)

10. Bashirov M., Yusupova I., Bitkulov R. Comparative analysis of software and computing systems for the design of power supply systems. Vestnik of Kazan State Power Engineering University. 2021;13(1):37–51. (In Russ.)

11. Trunov S. S., Krupnov A. V. CAD with independent design of power supply systems, taking into account the criteria of reliability and efficiency. Vestnik of Tver State Technical University. Series «Building. Electrical engineering and chemical technology». 2024;(1):57–74. (In Russ.) https://doi.org/10.46573/2658-7459-2024-1-57-74

12. Anishchenko V. A., Kirspu A. Yu. Accounting for the uncertainty of initial information in the design of power supply systems. Vestnik Gomel’skogo Gosudarstvennogo Tekhnicheskogo Universiteta imeni P. O. Sukhogo. 2005;(3):25–29. (In Russ.)

13. Fedosha D. V. Optimal design of power system. Elektrotekhnika i Elektroenergetika. 2012;(1):57–61. (In Russ.)

14. Stepanov V. M., Kosyrikhin V. S. Methodology of calculation and design of electric networks of system of industrial power supply. Izvestiya Tula State University. Technical Sciences. 2014;(8):215–222. (In Russ.)

15. Romanova V. V. The program for determining the optimal location for installation of symmetry facilities in 0.4 kV power supply systems with a motor-drive load. Journal of Siberian Federal University. Engineering and Technologies. 2020;13(5):643–651. https://doi.org/10.17516/1999-494X-0253

16. Yakovkina T. N., Starodubtsev A. A., Chekhovskiy S. N. Designing the power supply system for the sulfate soap decomposition department of the "ILIM" Group Branch in Bratsk. Proceedings of Bratsk State University. Series: Natural and Engineering Sciences. 2018;2:68–72. (In Russ.)

17. Dobrodey A. O., Voronovich A. A. Automation of calculations in the designing of power supply systems of residential buildings. Agrotekhnika i Energoobespechenie. 2018;(1):35–46. (In Russ.)

18. Savchuk I. V., Smolin N. I., Serov A. I. Automation of short-circuit current and voltage loss calculations in power supply systems and integration into a CAD system. AgroEkoInfo. 2023;(5). (In Russ.) https://doi.org/10.51419/202135539

19. Volkov N. A. The introduction of BIM technologies in the process of designing power supply networks. Scientifically Technical and Economical Cooperation in Asia-Pacific Countries in the 21st Century. 2024;2:19–23. (In Russ.)

20. Pichuev A. V., Gribkova O. S., Burmatova E. K. Assessment of energy efficiency of alternative power sources in independent power supply systems of mining and processing plants. Energy Safety and Energy Economy. 2024;(4):43–49. (In Russ.)

21. Sofronov M. A., Petrov V. L. Prospects for solar power plants in electricity supply systems in mines. Mining Informational and Analytical Bulletin. 2024;(10):152–165. (In Russ.) https://doi.org/10.25018/0236_1493_2024_10_0_152

About the Authors

V. L. PetrovRussian Federation

Vadim L. Petrov – Dr. Sci. (Eng.), Vice-Rector, Professor of the Department of Energy and Energy Efficiency of the Mining Industry

Moscow

Scopus ID 8919065900

ResearcherID P-9984-2015

E. K. Burmatova

Russian Federation

Elizaveta K. Burmatova – Design Engineer of the Electrical Engineering Department

Moscow

A. V. Pichuev

Russian Federation

Alexander V. Pichuev – Dr. Sci. (Eng.), Professor of the Department of Energy and Energy Efficiency of the Mining Industry

Moscow

Scopus ID 57209798580

Supplementary files

Review

For citations:

Petrov V.L., Burmatova E.K., Pichuev A.V. Integration of digital technologies into the design process of power supply systems for mining enterprises. Mining Science and Technology (Russia). 2025;10(4):393–403. https://doi.org/10.17073/2500-0632-2025-09-461