Scroll to:

Influence of the sorption properties of potash salts on the gas environment in dead-end mine workings

https://doi.org/10.17073/2500-0632-2024-01-210

Abstract

The results of gas-air surveys conducted at the mines of the Verkhnekamsk potassium-magnesium salt deposit indicate that the volume of gaseous impurities recorded in the main ventilation drifts is often significantly lower than in the working areas of dead-end workings. Many studies attribute the reduction of gas impurities along the ventilation airflow path in potash mines not only to the dilution of harmful impurities due to fresh air leakage from intake drifts but also to the neutralization of gases through chemical reactions with the potash rock mass. Previous laboratory studies have shown that sylvinite (NaCl + KCl) is capable of absorbing impurities of toxic and combustible gases. Based on these laboratory findings, the present study was conducted under real mining conditions, taking into account the dynamics of gas impurities in the underground atmosphere and the dilution effect caused by air leakage. As part of this study, measurements of combustible and toxic gas concentrations were conducted in productive seams of varying mineral composition at one of the mines of the Verkhnekamsk potassium-magnesium salt deposit to assess the influence of potash salt properties on the gas balance in long dead-end workings. An analysis was conducted to assess the extent to which the properties of the potash rock mass influence changes in the concentration of combustible and toxic gases in the workings along the ventilation airflow path. The collected air samples were analyzed under laboratory conditions. The concentration of combustible gases, carbon monoxide, and carbon dioxide in the collected air samples was determined using gas chromatography with the CHROMOS GX-1000 instrument. The contribution of gas neutralization and dilution due to leakage from the ventilation ducting to the reduction of combustible and toxic gases in the outgoing airflow from the working area was evaluated. The results of the conducted tests established that in long dead-end chambers of seam AB (100 m or more), the volume of gaseous impurities decreases along the length of the working from the dead end to the entry. The study accounted for factors that could influence the reduction of gas concentration in the working area.

Keywords

For citations:

Starikov A.N., Maltsev S.V., Sukhanov A.E. Influence of the sorption properties of potash salts on the gas environment in dead-end mine workings. Mining Science and Technology (Russia). 2025;10(1):25-33. https://doi.org/10.17073/2500-0632-2024-01-210

Influence of the sorption properties of potash salts on the gas environment in dead-end mine workings

Introduction

The Verkhnekamsk potassium-magnesium salt deposit (VPMSD) is mined using mechanized methods with continuous miner complexes for development and extraction. This method of ore extraction is almost always accompanied by the release of combustible and toxic gases from the rock mass during its fragmentation. Additionally, gas emissions originate from the broken ore stockpiled in the transfer hoppers and mine shuttle cars, as well as from the exposed potash rock mass adjacent to the mine workings. The accumulation of significant gas concentrations in the mine atmosphere is influenced by the release of free gases from the ore body. The primary composition of free gases at VPMSD includes combustible gases – methane (CH₄) and hydrogen (H₂) – and toxic gases such as hydrogen sulfide (H₂S). Furthermore, internal combustion engines, welding operations, and other industrial activities, contribute to the accumulation of carbon monoxide (CO) and other toxic gaseous impurities in the mine atmosphere[1] [1].

The dilution and removal of harmful impurities released in working areas, i.e., the creation of a safe environment for normal physiological activity, are ensured through ventilation.

The fresh airflow, passing through the working area, carries away the released harmful impurities through the ventilation drifts to the ventilation shaft and then to the surface. Gas surveys at the mines of the Verkhnekamsk potassium-magnesium salt deposit are conducted to determine the relative gas content in working areas. The obtained values of relative gas content directly affect the calculation of the required volume of fresh air for mine working ventilation. Determining accurate concentrations of combustible and toxic gases in the mine atmosphere is critically important for designing an effective ventilation system for the working areas and ensuring safe conditions in the mine.

Statistical analysis of long-term gas-air survey results conducted at the mines of VPMSD shows that the volume of gaseous impurities recorded in the main ventilation drifts is often significantly lower than in dead-end faces [2].

The reduction in the volume of gaseous impurities along the ventilation airflow path cannot always be explained solely by the dilution of contaminated air due to leaks from intake workings. The phenomenon of decreasing gas impurity concentration along the ventilation airflow path in potash mines has previously attracted attention in several studies. For instance, Medvedev I. I. and Krasnoshtein A.E. [3] described the ability of potash salts.

to actively sorb gaseous impurities from the mine atmosphere. The authors attribute the nature of the gas neutralization process to the natural radioactivity of potash ores, which facilitates chemical reactions between gas molecules and mineral particles on the surface of the rock mass. Similarly, Selivanova S.A.[2] also described the sorption of harmful impurities from the air by potash salts through a series of chemisorption processes. These processes involve chemical reactions induced by the catalytic effect of ionizing radiation from the potassium-40 isotope and the high hygroscopicity of potash salts. The ability of potash salts to absorb inorganic and organic gaseous substances was also discussed in [4], where research findings contributed to the establishment of an underground allergology inpatient facility in an active potash mine. The processes of natural air purification in salt mines, influenced by the mineral composition of the rock mass, were previously examined in studies [5, 6]. Additionally, international literature associates the mechanism of air self-purification in salt mines with intermolecular attraction forces [7, 8].

The results of experimental studies presented in [9] have demonstrated in detail that sylvinite (NaCl + KCl) is capable of absorbing impurities of toxic and combustible gases. The study analyzed the nature of gas sorption processes by potash salts and suggested that natural radioactivity does not play a primary role in gas absorption by the potash rock mass. A hypothesis was proposed that intermolecular interaction forces are the fundamental mechanism underlying the gas sorption process in the potash rock mass [10].

If the absorption of gaseous impurities from the mine atmosphere by potash salts can influence the gas balance within a dead-end working, it becomes necessary to account for these processes when conducting gas-air surveys, particularly during air sampling in dead-end workings [11]. Considering that the rock mass can actively absorb gaseous impurities, it can be assumed that the gas content in the air of a single working area may vary locally depending on the distance from the gas emission source. The risk of recording incorrect gas concentration values due to variations in concentration along the length of the working may lead to inaccurate calculations of the required air volume, potentially affecting the safety of mining operations. Therefore, a more detailed examination of the gas conditions within the dead-end chamber is necessary.

Studies conducted by the authors of [9] under laboratory conditions confirm the ability of potash salts to sorb combustible and toxic gases. The objective of this study is to analyze the dynamics of gas impurity concentration reduction in underground mine workings of a potash mine. The main tasks of the study include conducting a series of experimental observations in an active potash mine, analyzing the extent to which the sorption properties of potash salts influence the gas conditions, and assessing the impact of air leakage from the ventilation ducting on the reduction of gas impurity concentrations within dead-end mine workings.

[1] Ushakov K. Z., Burchakov A. S., Medvedev I. I. Mine Aerology. Moscow: Nedra Publ. House; 1978.

[2] Selivanova S. A. Hygienic aspects of formation and optimization of the physicochemical conditions of the internal environment in sylvinite structures. [Cand. Med. Sci. Dissertation] Perm: Perm State Medical University named after Academician E. A. Wagner; 2019.

Observation Methods

This study describes a series of experiments conducted in long dead-end stoping workings (over 100 m in length) at one of the VPMSD mines to analyze the relationship between changes in combustible and toxic gas concentrations along the ventilation airflow path from the gas emission source (from the face to the chamber entry). The research was carried out in productive seams AB and Kr-II to assess the influence of rock masses with different mineral compositions on gas concentration changes within the workings.

The general research approach involved air sampling and measuring airflow rates at multiple points along the entire length of the dead-end stopping working. All measurements during the experiment were performed while mining equipment was in operation and under stable ventilation conditions.

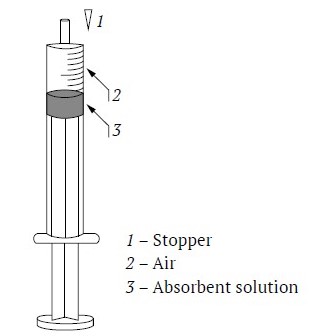

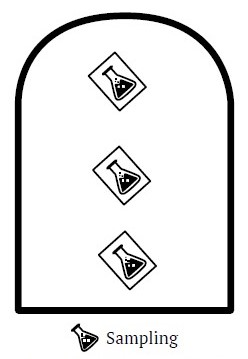

Air sampling was conducted to measure the concentration of combustible and toxic gases in the mine atmosphere, while airflow measurements were taken to determine gas volume and assess air leakage from the ventilation ducting. Sampling for combustible gases was performed using the 'wet method,' a traditional technique for collecting poorly soluble gases (CH4, H2, CO, CO2) [12], in which the sample was obtained through displacement using a 0.7 dm3 glass container filled with water (Fig. 1). To determine the concentration of soluble gas impurities (H2S, NO, and NO2) in the mine atmosphere, samples were collected using 0.15 dm³ medical syringes. Before sampling, 7 cm3 of ammonium molybdate absorbent solution was added to the syringe with a pipette, and the sample container was sealed with a stopper (Fig. 2).

Fig. 1. Sampling container for determining combustible gas concentration

Fig.2. Sampling syringe for determining hydrogen sulfide (H2S) concentration

At each sampling location, the sampling syringe was positioned vertically, and the stopper was removed. The plunger was then smoothly depressed to draw an air sample up to the 0.15 dm3 mark. Once the sample was collected, the syringe was sealed with the stopper and placed in a protective case for transport to the laboratory[3].

At each sampling point, a minimum of three air samples were taken (Fig. 3) to determine the average gas volume passing through the working. The collected samples were transported to the laboratory within two hours and analyzed within 12 hours of collection.

Fig. 3. Sampling method

The analysis of collected air samples was conducted under laboratory conditions. The separation of combustible gases (CH4 and H2), carbon monoxide (CO), and carbon dioxide (CO2) in the collected air samples was performed using gas chromatography with the CHROMOS GX-1000 instrument. The chromatograph operates by separating the air sample into individual chemical components and determining their concentrations using a detector. The volumetric fraction of each component was then measured using the instrument's software[4].

The mass concentration of hydrogen sulfide (H2S) was analyzed using the photometric method with ammonium molybdate reagent and a photoelectric colorimeter (KFK-3KM). This method is based on measuring the optical density of the compound formed when hydrogen sulfide is absorbed from the air by an ammonium molybdate solution [13]. The mass concentration of hydrogen sulfide was determined using a calibrated optical density–mass concentration relationship.

All measurements were performed in accordance with certified measurement methodologies[5] using approved measuring instruments that had undergone verification.

For the experiments, working areas in different productive seams at one of the VPMSD mines were selected. Field measurements were conducted in three stages: the first stage was carried out in seam Kr-II, while the second and third stages were conducted in seam AB. The primary criterion for selecting working areas was the presence of a long dead-end working – over 100 meters in length. The selected working areas were located within a single extraction site (panel), where preparatory mining operations were underway to develop a new extraction block, resulting in the significant length of the workings.

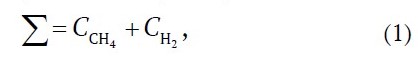

The experiment was designed to ensure uniform and simultaneous measurements at multiple points along the entire length of the chamber, as shown in Fig. 4.

Fig. 4. Measurement scheme for seam Kr-II

The first stage of the study involved a series of measurements in the working area of seam Kr-II. The primary mineral composition of this seam consists of potassium chloride (KCl) – 29% and sodium chloride (NaCl) – 66% [14]. During this stage, the distance from the chamber mouth to the face was 180 meters. The mining equipment operating in the working area included: Ural-20R continuous miner, BPS-25 transfer hopper, and VS-30 mine shuttle cars. entilation of the working area was provided by a VME-6 local ventilation fan. The fan was positioned in the extraction gallery, and air was supplied to the face using a forced ventilation system through a 500 mm diameter flexible ventilation duct (see Fig. 4). With this duct diameter and pipeline length, the fan's capacity ranged from 190 to 200 m3/min. The advance rate of the specified continuous mining complex averages 30 meters per shift. Air sampling in the working area was conducted during the third production shift, 30 minutes after the mining equipment began operating, and while it was in operation. Within the chamber, four measurement points were selected at 50-meter intervals from the face to the chamber mouth.

The second stage of the experiment was conducted in a dead-end chamber in seam AB. The mineral composition of this productive seam differs from that of seam Kr-II due to its higher potassium chloride (KCl) content – up to 39%. The experiment was carried out in a 130-meter-long dead-end working. At the time of the measurements, the mining complex in operation included: Ural-61 continuous miner, BP-14 transfer hopper, and VS-17V mine shuttle car. The technical productivity of this complex was 3 tons per minute. Ventilation of the working area was provided by a VME-6 local ventilation fan with a 500 mm diameter flexible ventilation duct. Under these operating conditions, the fan’s capacity ranged from 200 to 210 m3/min. The average advance rate of the mining complex was 30 meters per shift. Within the chamber, five measurement points were selected at 30–35 meter intervals from the face to the chamber mouth. Measurements were conducted during the loading cycle of the mine shuttle car at the continuous miner.

The measurement stages for seams Kr-II and AB involved air sampling to determine the concentrations of methane (CH4), hydrogen (H2), carbon monoxide (CO), and oxygen (O2). Additionally, at each sampling location, the airflow volume was recorded. The total sampling time per stage, excluding preparation, did not exceed 10 minutes.

Seam AB at the VPMSD mines, unlike seam Kr-II, is characterized by a tendency to release hydrogen sulfide (H2S) during extraction [15]. Therefore, as a separate stage of the study, air samples were collected in the chamber of seam AB to determine hydrogen sulfide (H2S) concentration. These measurements were conducted one month later in another chamber within the same extraction block.

The third stage of the experiment was conducted in a 100-meter-long dead-end chamber in seam AB. The mining equipment operating in the working area included: Ural-61 continuous miner, BP-14 transfer hopper, VS-17V mine shuttle car. Ventilation of the working area was provided by a VME-6 local ventilation fan with a 500 mm diameter flexible ventilation duct, operating at 205–215 m3/min. Within the chamber, three measurement points were selected—at the face, midpoint, and chamber mouth. Measurements were taken during the loading cycle of the mine shuttle car at the continuous miner. The measurement series included air sampling to determine hydrogen sulfide (H2S) concentration, while airflow volume was recorded at each sampling point. Additionally, a mine gas analyzer was placed at the face near the continuous miner (see Fig. 4), which recorded and stored hydrogen sulfide (H2S) concentration values every 10 seconds. The sampling time for each measurement was 10 minutes. The following section presents the results of sample analysis from all stages of the experiment.

[3] Laptev V. N., Kazakov B. P., Levin L. Yu. et al. Device for gas sampling in mines to determine hydrogen sulfide content. Utility Model Patent. 2014.

Laptev V. N., Isayevich A. G., Norina N. V. et al. Device for continuous sampling of a gas-air mixture over a specified time interval. Utility Model Patent. 2015.

[4] Chudin E. A. Computer program: software module for controlling the column thermostat of a gas chromatograph.

[5] FR.1.31.2022.42903 GSI. Measurement methodology for determining the volumetric fraction of oxygen, methane, and carbon dioxide, as well as the mass concentration of carbon monoxide, hydrogen sulfide, nitric oxide, and nitrogen dioxide in the atmosphere of mine workings, and for assessing gas emission levels based on combustible gases in mine workings and the mine as a whole

FR.1.31.2022.44212 Measurement methodology for determining the mass concentration of hydrogen sulfide (hydrosulfide, hydrogen sulfide) using ammonium molybdate reagent.

Experiment results

The analysis of samples collected using chromatographic and photometric methods provides an assessment of changes in combustible and toxic gas concentrations along the outgoing airflow path in the chamber, from the face to the chamber mouth. Collecting three samples at each measurement point allows for an evaluation of data variability and determination of average concentration values. Sample processing was carried out under controlled laboratory conditions, ensuring compliance with all necessary environmental parameters. In accordance with the methodology, the concentration of combustible gases was analyzed by separately measuring methane (CH4) and hydrogen (H2) concentrations, followed by their summation, expressed as (%):

where C is concentration of the specified component, %.

The obtained concentration values for the studied components are presented as scatter plots, with trend lines plotted based on the average concentration values of each component.

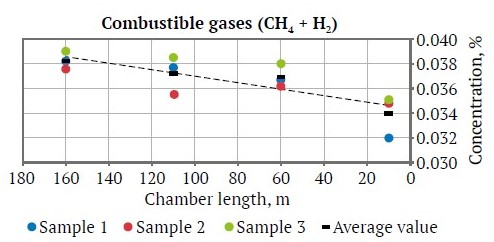

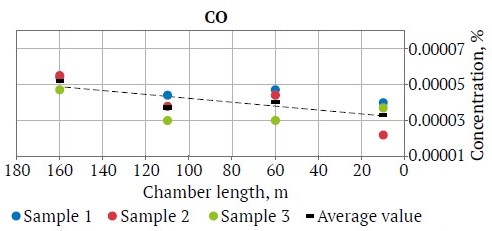

Figs. 5 and 6 show the concentration values of combustible gases (CH4 + H2) and carbon monoxide (CO) obtained from the analysis of samples collected along the entire length of the chamber in seam Kr-II during the first stage of the experiment.

Fig. 5. Concentration of combustible gases in seam Kr-II

Fig. 6. Concentration of carbon monoxide in seam Kr-II

According to the obtained results, a decrease in the volumetric fraction of the studied gas components was observed in the working area of seam Kr-II along the airflow path from the face to the chamber mouth. Over a 150-meter distance, the average concentration of combustible gases (CH4 + H2) decreased by 10%, while the average concentration of carbon monoxide (CO) dropped by 17%.

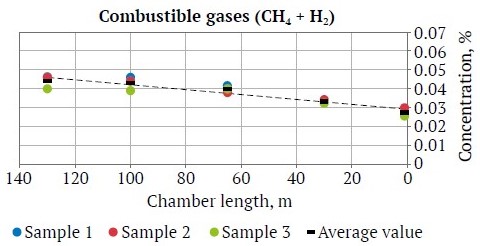

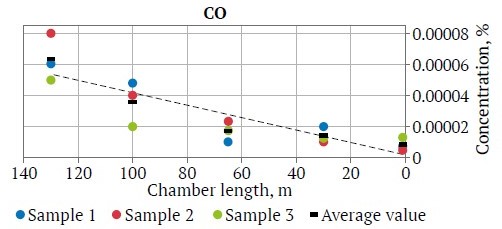

The measured concentrations of combustible gases and carbon monoxide from air samples collected during the second stage of the experiment in seam AB are presented in Figs. 7 and 8.

Fig. 7. Concentration of combustible gases in seam AB

Fig. 8. Concentration of carbon monoxide in seam AB

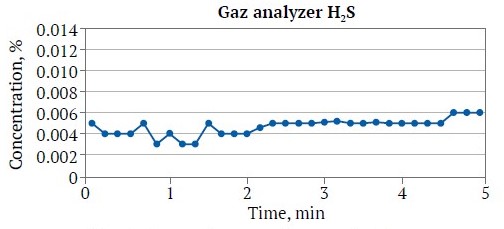

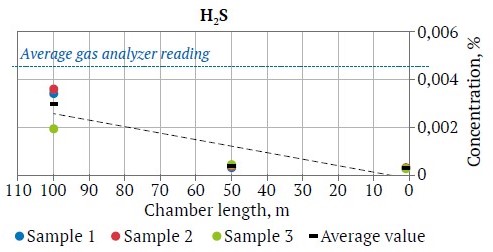

The processing of air samples collected in the working area of seam AB indicates a decrease in gas impurity concentrations within the chamber atmosphere, along the airflow path from the face to the chamber mouth. Over a 130-meter distance, the average concentration of combustible gases (CH4 + H2) decreased by 37%, while the carbon monoxide (CO) concentration dropped by 88%. Air sampling in seam AB, as part of the third stage of the experiment, was conducted alongside the continuous recording of hydrogen sulfide (H2S) concentrations at the face using a mine gas analyzer. The gas analyzer readings during the air sampling period are presented as a graph in Fig. 9.

The average concentration of hydrogen sulfide (H2S) recorded by the gas analyzer near the continuous miner, where gas is predominantly released from the rock mass, was 0.0047%. The hydrogen sulfide (H2S) concentration values obtained from the analysis of air samples collected during the third stage of the experiment in seam AB are presented in Fig. 10.

The analysis of air samples collected in the working area of seam AB shows a decrease in hydrogen sulfide (H₂S) concentration along the outgoing airflow path from the face to the chamber mouth. Over a 100-meter distance, the average concentration of hydrogen sulfide in the air decreased by 90%.

Fig. 9. Gas analyzer readings at the face

Fig. 10. Concentration of hydrogen sulfide in seam AB

Analysis of Results

The measurement results obtained in this study clearly demonstrate a reduction in gas impurity concentrations in extended working areas as air moves from the face (gas emission source) to the mouth of the dead-end chamber. Air sampling in the working areas of seams Kr-II and AB provides insight into the impact of different mineral compositions on the absorption of gas impurities from the atmosphere in dead-end working [16].

The results indicate that the reduction in gas impurity concentrations in the working area of seam AB occurs more intensively compared to seam Kr-II, under identical dead-end chamber lengths. Table 1 presents the percentage reduction in gas impurity concentrations for different seams over a 100-meter section of the ventilation airflow path within the chamber. This 100-meter segment was chosen to ensure the standardization of conditions across all stages of the study.

Table 1

Reduction in gas concentration in the stoping chamber

Seam | Reduction in concentration over 100 m, % | ||

Combustible gases | Carbon monoxide СО | Hydrogen sulfide H2S | |

Seam Кr-II | 9 | 12 | – |

Seam АB | 35 | 76 | 90 |

The reduction in gas impurity concentration as air moves from the face to the chamber mouth can be attributed not only to the absorption of gaseous impurities by the rock mass[1] [17] but also to the dilution of the outgoing airflow due to fresh air leakage from the ventilation duct into the chamber atmosphere. The extent to which the sorption properties of the rock mass influence the reduction of gas impurity concentrations in the outgoing airflow can only be accurately assessed by determining the volume of air leakage from the ventilation duct along the studied section [18].

At each stage of the study, measurements were taken to determine air leakage from the ventilation duct. Specifically, airflow was measured at the sampling points using a mine vane anemometer. The air velocity measurements recorded in this study showed no significant variation between the measurement points within the chamber. The air volume at each measurement point ranged from 200 to 215 m³/s, accounting for the acceptable calibration error of the anemometer at the recorded air velocities, calculated as +(0.03 + 0.02V), where V is the measured velocity (m/s).

Since direct measurement of air leakage from the ventilation duct along the studied section of the chamber was not feasible, the leakage volume was estimated based on regulatory air leakage rates outlined in the official documentation used at VPMSD mines to calculate the required ventilation airflow in dead-end chambers[2]. The regulatory air leakage rate represents the maximum permissible leakage from the ventilation duct under normal conditions, assuming no structural damage and nominal performance of the local ventilation fan. Under standard operating conditions, for a 100-meter-long flexible ventilation duct, the air leakage coefficient is set at 1.07. Consequently, in the analyzed sections of the dead-end chambers in seams Kr-II and AB, the air volume at the face was considered 7% lower than the air volume passing through the chamber mouth.

With known airflow values, the measured gas concentrations (%) were converted into the gas volume passing through the studied points (m³/min). When assessing changes in gas volume (m³/min) along the working, the influence of air leakage from the ventilation duct on the concentration of harmful impurities in the ventilation airflow path (from the face to the chamber mouth) was excluded. Therefore, changes in gas volume along the working reflect the impact of the sorption properties of the rock mass surrounding the excavation on the gas balance within the dead-end chambers at VPMSD mines.

Table 2 presents the changes in the average volume of gas impurities passing through the working, as well as the sorption capacity of the rock mass for each seam, as determined in this experiment.

Table 2

Reduction in gas volume in the studied working areas

Steam | Gas volume at measurement point, m³/min | Reduction, % | |

Face | Chamber mouth | ||

Seam Кr-II (KCl 29 %) | |||

Combustible gases (CH4 + H2) | 0.07099 | 0.06895 | 3* |

Carbon monoxide СО | 0.000072 | 0.000067 | 7 |

Seam АB (KCl 39 %) | |||

Combustible gases (CH4 + H2) | 0.08170 | 0.05613 | 31 |

Carbon monoxide СО | 0.000068 | 0.000017 | 75 |

Hydrogen sulfide H2S | 0,00566 | 0,00059 | 88 |

The data presented in Table 2 indicate that gas volume in dead-end chambers decreases from the face to the chamber mouth. The most intensive reduction in gas impurity concentrations occurs in the dead-end chambers of seam AB, which is consistent with laboratory experiments [7], where a higher KCl content in sylvinite was shown to have a stronger sorption effect on gas impurities.

The very minor reduction in combustible gases and carbon monoxide concentrations in seam Kr-II does not allow for definitive conclusions regarding the sorption properties of the rock mass in this seam. The slight variations observed may be attributed to the measurement uncertainty of the equipment and methodology. A more precise assessment of gas impurity reduction in seam Kr-II would require increasing the length of the studied working.

[6] Gorbatenko Yu. A. Adsorption of toxic gas impurities from contaminated air. 2014.

[7] Temporary guidelines for calculating the required air volume for ventilation of ore mines. 1983.

Conclusion

This study involved a series of experimental observations conducted in underground dead-end workings of a potash mine, specifically in productive seams Kr-II and AB. Based on the results of the experiments, an analysis was performed to assess the impact of the sorption properties of potash salts on the gas environment within dead-end working areas. Additionally, the influence of air leakage from ventilation ducts on the reduction of gas impurity concentrations was evaluated.

The experimental investigations revealed that in extended dead-end chambers of seam AB (100 meters or longer), a gradual reduction in gas impurity concentrations was observed along the working, from the face to the chamber mouth. The obtained data align with previous laboratory experiments [9], which demonstrated that potash salts are capable of absorbing carbon monoxide (CO) and combustible gases, such as hydrogen (H2) and methane (CH4). Furthermore, this study included experiments in seam AB to examine the dynamics of hydrogen sulfide (H2S) concentration changes during ore extraction, as air moves from the face to the chamber mouth. The experimental results showed that the average sorption efficiency of sylvinite from seam AB (with KCl content of 39%) over a 100-meter ventilation path from the dead-end to the chamber mouth was: 31% for combustible gases (hydrogen (H2) and methane (CH4)), 75% for carbon monoxide (CO), and 88% for hydrogen sulfide (H2S). During the study, factors influencing gas concentration reduction in the working area were considered. Additionally, the ventilation duct leakage coefficient was accounted for when converting gas impurity concentrations to actual gas volume passing through the measurement control points.

This research continues the investigation of the sorption properties of potash salts concerning the absorption of combustible and toxic gas components from the mine atmosphere. The observations of the impact of potash salts' sorption characteristics on mine air composition in extended dead-end workings at the VPMSD mine serve as a continuation of a series of laboratory experiments [7]. The findings of this study will contribute to the further development of methodologies for evaluating factors affecting the mine atmosphere composition within dead-end workings. Additionally, the results will provide a basis for the development of a gas survey methodology for working areas in potash mines. In the future, the study is expected to be expanded to cover all VPMSD mines, enabling the accumulation of statistical data and the testing of an improved gas survey methodology for potash mining operations.

References

1. Kuzminykh E. G., Levin L. Yu., Maltsev S. V. Distribution of exhaust gas products from machinery with internal combustion engines through the shaft ventilation system. Gornoye Ekho. 2023;(2):96–103. (In Russ.) https://doi.org/10.7242/echo.2023.2.17

2. Trushkova N. A. Investigation of the gas composition of mine air to assess the possibility of using recirculating ventilation. Gornoye Ekho. 2019;(3):84–87. (In Russ.) https://doi.org/10.7242/echo.2019.3.23

3. Medvedev I. I., Krasnoshtein A. E. Aerology of potash mines. Sverdlovsk: Academy of Sciences of the USSR; 1990. Pp. 119–126. (In Russ.)

4. Barannikov V. G., Krasnoshtein A. E., Papulov L. M. et al. Speleotherapy in a potash mine. Yekaterinburg: Publishing House of the Ural Branch of the Russian Academy of Sciences; 1996. Vol. 173. (In Russ.)

5. Puławska A., Manecki M., Flasza M. et al. Origin, distribution, and perspective health benefits of particulate matter in the air of underground salt mine: a case study from Bochnia, Poland. Environmental Geochemistry and Health. 2021;43(9):3533–3556. https://doi.org/10.1007/s10653-021-00832-2

6. Calin M., Zoran M., Calin M. Radon levels assessment in some Northern Romanian salt mines. Journal of Radioanalytical and Nuclear Chemistry. 2012;293(2):565–572. https://doi.org/10.1007/s10967-012-1686-1

7. Yao N., Chen J., Feng R. et al. Mechanistic understanding of adsorption of low concentrations of N-nitrosodiethylamine in water by functional MIL-96: experiments and theoretical calculations. Chemical Engineering Journal. 2022;451(3):138761. https://doi.org/10.1016/j.cej.2022.138761

8. Yang D., Peng X., Peng Q. et al. Probing the interfacial forces and surface interaction mechanisms in petroleum production processes. Engineering. 2022;18:49–61. https://doi.org/10.1016/j.eng.2022.06.012

9. Sukhanov A. E., Bruev N. A., Gazizullin R. R., Starikov A. N. Research of sorption properties of salt on the example of gases contained in the atmosphere of potash mines. Izvestija Tulskogo Gosudarstvennogo Universiteta. Nauki o Zemle. 2023;(1):495–507. (In Russ.) https://doi.org/10.46689/2218-5194-2023-1-1-495-507

10. Kuznetsovа Y. L. Size evolution of a soluble aerosol particle in air. Computational Continuum Mechanics. 2022;15(1):31–44. https://doi.org/10.7242/1999-6691/2022.15.1.3

11. Barannikov V. G., Chereshnev V. A. Hygienic assessment of air self-purification processes in a potassium mine. In: Safety problems in the exploitation of mineral deposits in urban agglomerations: Abstracts of the International Symposium. Moscow, Perm: 1995. Pp. 12–13. (In Russ.)

12. Isaevich A. G., Starikov A. N., Maltsev S. V. Improvement of air sampling method to determine relative concentration of combustion gases in mine air. Mining Informational and Analytical Bulletin. 2021;(4):143-153. (In Russ.) https://doi.org/10.25018/0236_1493_2021_4_0_143

13. Norina N. V., Isaevich A. G. Methods and technical means of neutralization sulfur-containing gases in the atmosphere of potassium mines. Izvestija Tulskogo Gosudarstvennogo Universiteta. Nauki o Zemle. 2021;(4):550–557. (In Russ.)

14. Smetannikov A. F., Filippov V. N. Some features of the mineral composition of salt rocks and their processed products using the example of Verkhnekamskoe salt deposit. Problems of Mineralogy, Petrography and Metallogeny. Scientific Readings in Memory of P.N. Chirvinsky. 2010;13:99–113. (In Russ.)

15. Zemskov A. N., Liskova M. Yu. Features formation of component composition of gases of potash fields. Izvestija Tulskogo Gosudarstvennogo Universiteta. Nauki o Zemle. 2019;(2):88–97. (In Russ.)

16. Gazizullin R. R., Isaevich A. G., Levin L. Yu. Numerical modeling of the processes for removing harmful impurities from mine atmosphere during ventilation of dead-end workings using various methods. Scientific Researches and Innovations. 2011;5(2):127–129. (In Russ.)

17. Krasnoshtein A. E. Physico-chemical mechanisms in the process of adsorption of toxic impurities from the mine atmosphere using potash salts. Perm: Perm Polytechnic Institute; 1977. (In Russ.)

18. Zhu X., Wen H. Numerical simulation study on the influence of air leakage on oxygen concentration in goafs of fully mechanized caving mining with shallow buried and large mining height. Frontiers in Earth Science. 2023;11:1138925. https://doi.org/10.3389/feart.2023.1138925

About the Authors

A. N. StarikovRussian Federation

Alexey N. Starikov – PhD-Student; Engineer of the Department of Aerology and Thermophysics

Perm

S. V. Maltsev

Russian Federation

Stanislav V. Maltsev – Cand. Sci. (Eng.), Head of the Mine Ventilation Sector of the Department of Aerology and Thermophysics

Perm

A. E. Sukhanov

Russian Federation

Andrey E. Sukhanov – PhD-Student, Junior Researcher at the Department of Aerology and Thermophysics

Perm

Review

For citations:

Starikov A.N., Maltsev S.V., Sukhanov A.E. Influence of the sorption properties of potash salts on the gas environment in dead-end mine workings. Mining Science and Technology (Russia). 2025;10(1):25-33. https://doi.org/10.17073/2500-0632-2024-01-210

JATS XML