Scroll to:

Substantiation of environmental safety in metro facility operations considering hydrogeological risks

https://doi.org/10.17073/2500-0632-2024-04-259

Abstract

In today’s world of rapid urbanization, environmental safety has become a key aspect of urban planning and management. The issue of environmental safety encompasses a wide range of concerns, from pollution reduction and biodiversity conservation to ensuring the sustainable use of natural resources. In this context, metro facilities, as an integral part of urban infrastructure, play a crucial role in providing mobility for urban populations, yet they also pose potential environmental challenges. The operation of metro facilities is associated with noise pollution, emissions of harmful substances due to the use of energy produced from fossil fuels, energy consumption, undesirable impacts on groundwater, and other negative environmental aspects. Equally important is the issue of waste disposal and the use of construction materials during the building and maintenance of metro systems. The aim of this study was to assess the environmental safety of metro facility operations. The consideration of this topic is particularly relevant in light of global efforts towards sustainable development and the need to ensure a high quality of life for urban populations. The assessment of environmental safety in metro operations is proposed to be conducted through a comprehensive approach, involving field studies and modelling the distribution patterns of defects in metro structures under the influence of hydrogeological risks. A systematic approach to evaluating environmental safety in metro operations, based on modelling the development of defects in tunnel structures under the influence of hydrogeological factors, will help organize existing information on potential accidents and develop monitoring methods and measures to minimize risks that compromise the environmental sustainability of underground transport infrastructure. The research results, which include the systematization of environmental safety criteria for metro operations and the analysis of tunnel structure defects caused by hydrogeological factors, provide the basis for further developing methods to ensure environmentally safe operation of urban transport tunnels.

Keywords

For citations:

Zhukov S.A. Substantiation of environmental safety in metro facility operations considering hydrogeological risks. Mining Science and Technology (Russia). 2024;9(3):283-291. https://doi.org/10.17073/2500-0632-2024-04-259

Substantiation of environmental safety in metro facility operations considering hydrogeological risks

Introduction

To assess the environmental safety of metro systems, several key criteria must be considered to help ensure their sustainable operation.

Hydrogeological criterion. This includes determining the hydrostatic pressure of groundwater, its mineralization, and composition.

Pollutant emissions. This involves measuring levels of carbon dioxide emissions, nitrogen oxides, and other pollutants that may affect air quality in cities. Particular attention should be given to areas with high concentrations of people, such as metro stations and transfer hubs.

Noise pollution. Metro operations are often accompanied by high noise levels, which can negatively affect the health and quality of life of city residents. It is important to assess noise levels and take measures to reduce them.

Energy efficiency. Efficient energy use is a key factor in reducing the environmental impact of metro systems. This includes the use of energy-saving technologies and transitioning to renewable energy sources.

Waste management and material use. Proper waste management during the construction and operation of metro systems, as well as the selection of environmentally sustainable materials, are critical aspects.

Impact on ecosystems and biodiversity. It is necessary to consider the impact of metro systems on natural ecosystems, particularly during the construction of new metro lines and the development of infrastructure.

Applying these criteria requires a comprehensive approach that includes regular monitoring, the use of modern technologies, and innovative solutions. It is also essential to develop and implement regulatory frameworks that govern the environmental aspects of metro operations.

Environmental safety criteria should be regularly reviewed and updated in accordance with the latest scientific research and technological advancements. This will ensure adaptability and continuous improvement in response to changing conditions and potential emergencies.

Implementing these criteria will not only reduce the negative environmental impact of metro systems but also increase their efficiency and convenience for both staff and passengers, thus contributing to the sustainable development of urban transport systems.

Examples of best practices

Stockholm Metro, Sweden. One of the most environmentally friendly metro systems in the world. Thanks to the use of 100% renewable energy for metro trains, Stockholm has significantly reduced the carbon footprint of its transport system. Additionally, efficient ventilation and noise reduction systems have been implemented.

Singapore Metro. An example of a highly efficient and innovative transport system. The Singapore metro uses regenerative braking, which helps reduce overall energy consumption. Strict standards for noise and air pollution reduction are also applied.

London Underground, United Kingdom. A program has been introduced to reduce energy consumption and improve air quality. The London Underground is also actively working on improving its infrastructure to reduce noise and vibration levels.

Examples of problematic aspects

New York City Subway, USA. Despite its size and significance, it faces several environmental challenges, primarily related to outdated infrastructure and high noise levels. Projects for infrastructure modernization and energy efficiency improvement are in development and implementation stages.

Moscow Metro, Russia. Although steps have been taken in recent years to improve environmental safety, such as the introduction of energy-efficient lighting and improved ventilation, challenges remain related to the aging infrastructure and changing geological and hydrological conditions due to urban landscape transformations.

Materials and methods

One of the most hazardous environmental risks in underground metro facilities, which significantly reduces environmental safety, is hydrogeological risk. This refers to potential social and economic losses resulting from the development of adverse hydrogeological processes, which manifest as a reduction in the stability of metro tunnels and environmental safety within the “rock mass–underground structure–environment” system. Hydrogeological risks are evidenced by the formation of defects in the supporting structures of tunnels, such as leaks, water ingress, soil washouts into underground facilities, water breakthroughs, and quicksand.

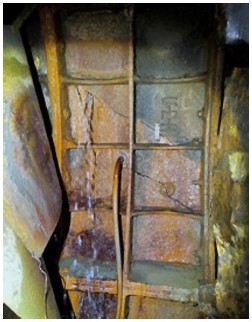

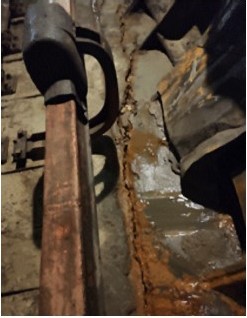

As an example, we can consider the assessment of environmental safety at an existing Moscow metro facility, based on data from engineering geological surveys conducted over different periods. Photographs of the Moscow metro tunnel are shown in Figs. 1–3.

Fig. 1. Leaching and wet spots at the inter-ring and inter-block joints of the tubbing lining, active leakage. Crack in the back of the tubbing

Fig. 2. Soil washout into the area of the contact rail

Fig. 3. Leaching and destruction of the concrete structure of the roof slab due to erosion of the waterproofing barrier

During the in-situ inspection of the structures at the emergency section of the running tunnel of the Moscow Metro line, the following most characteristic defects and damages were identified:

- concrete spalling in wall blocks, including areas with exposed reinforcement;

- concrete spalling in roof slabs, including areas with exposed reinforcement;

- leaching observed on the wall blocks of the running tunnel;

- leaching observed on the roof slabs of the running tunnel;

- wet spots on the wall blocks of the running tunnel;

- disruption of joint sealing in wall blocks and roof slabs;

- active leakages;

- cracks in the roof slabs with an aperture width of up to 0.2 mm.

The classification of the identified defects is reflected in Table 1.

Table 1

Classification of defects (according to GOST R 57208–2016)

No | Type of defect | Possible causes | Potential consequences |

1 | Concrete spalling in wall blocks and roof slabs, including areas with exposed reinforcement | Mechanical impact | Reduction in load-bearing capacity proportional to the decrease in cross-sectional area |

2 | Leaching on wall blocks and roof slabs of the running tunnel. Wet spots on wall blocks. Dripping. Active leakages | Waterproofing failure | Concrete degradation, metal and reinforcement corrosion, reduction in operational performance |

3 | Steps at the joints of the roof slabs in the running tunnel up to 30 mm | Errors during manufacturing and installation | The degree of reduction in load-bearing capacity is determined by calculation |

4 | Cracks in roof slabs with an aperture width of up to 0.2 mm | Shrinkage due to the heat and moisture treatment of the concrete mix, properties of the cement, etc. | No effect on load-bearing capacity. May reduce durability |

5 | Disruption of joint sealing in wall blocks and roof slabs | Tunnel and metro operations (including vibrations from moving trains) | Increased water infiltration and reduced operational performance of the structure |

Results

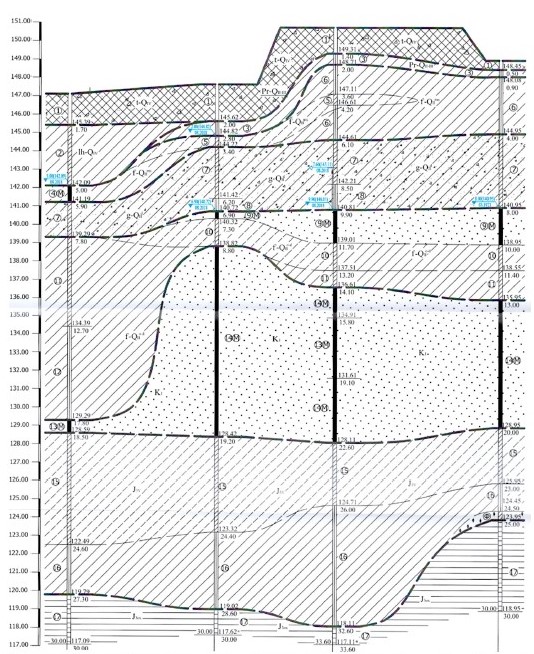

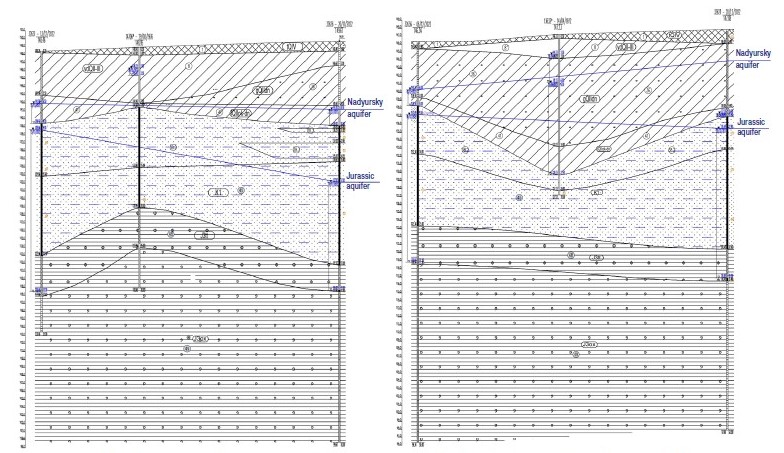

The geological cross-sections of the examined section of the running tunnel, observed over different time periods, are shown in Figs. 4 and 5.

Fig. 4. Geotechnical cross-section of the running tunnel section between stations at time period t1

Fig. 5. Geotechnical cross-section of the running tunnel section between stations at time period t2

From the presented cross-sections, it can be concluded that the level of the aquifer has changed over time, which significantly affected the physical and mechanical properties of the rock and the development of defects in the load-bearing structures of the tunnel, primarily influencing the geometry of the tunnel lining.

To determine the rate of decline and recovery of water inflow, calculations of the filtration properties of the aquifer near the running tunnel were conducted (Table 2).

Table 2

Aquifer characteristics

Type of aquifer | Confined |

Aquifer thickness, H (m) | 17.8 |

Well radius, m | 0.063 |

Pumping duration, days | 0.5 |

Discharge rate, m³/day | 64.8 |

Static water level, m | 7.2 |

Dynamic water level, m | 23.45 |

Water level drawdown, m | 16.25 |

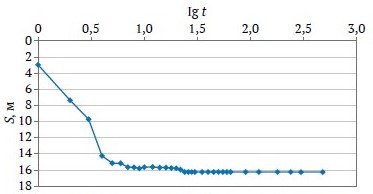

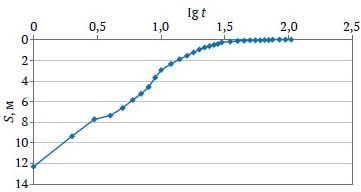

Based on observations of the aquifer level near the running tunnel, changes in the hydrological regime were identified (Figs. 6 and 7). The presented graphs indicate that over an extended period, the aquifer level fluctuated within a range of 2 to 16 m.

Fig. 6. Graph tracking the decline of the water level in the well

Fig. 7. Graph tracking the recovery of the water level in the well

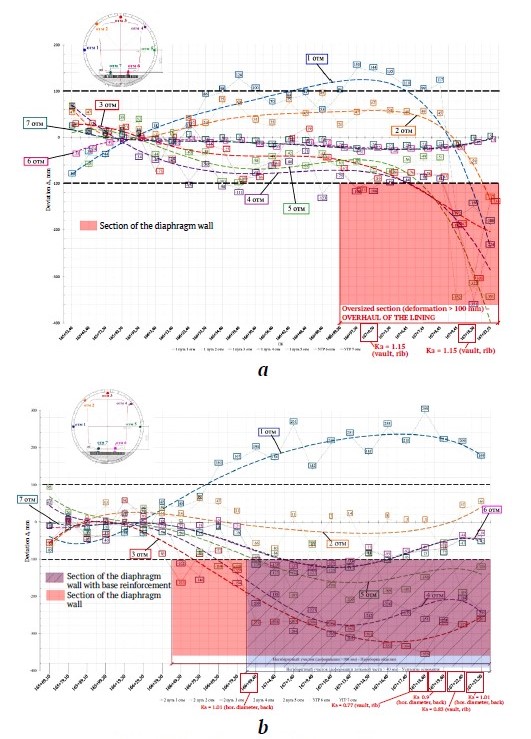

As part of the inspection of the technical condition of problematic sections of running tunnels, in-situ measurements of the actual geometric dimensions of the tunnel structures were carried out. The measurements of the actual dimensions of the studied structures were conducted using a Leica DISTO D2 handheld laser distance meter. Measurement accuracy: ±1.5 mm. Based on the measurement results, deviations of the actual geometric dimensions of the tunnel lining from the design values were identified, with deviations exceeding 50 mm at the examined chain ages (Fig. 8). The area highlighted in Fig. 8, a represents an oversized section of the metro tunnel lining that could lead to the development of a potential emergency situation. The area highlighted in red in Fig. 8, b shows an oversized section of the metro tunnel lining before the process of reinforcing the base of the trough zone, which could also create a potential emergency risk. The blue-highlighted area shows the results of measurements taken after the reinforcement process, which reduced the deformation from 100 to 40 mm.

Fig. 8. Deformation graph of the tunnel lining: a – for the first track (left running tunnel); b – for the second track (right running tunnel)

From Fig. 8, it follows that deformation processes caused by increased groundwater inflow to the tunnel lining lead to cracking in the cast iron tubbing structure. This, in turn, contributes to the formation of leaks and soil washouts into the interior space of the tunnel, including onto the track sections.

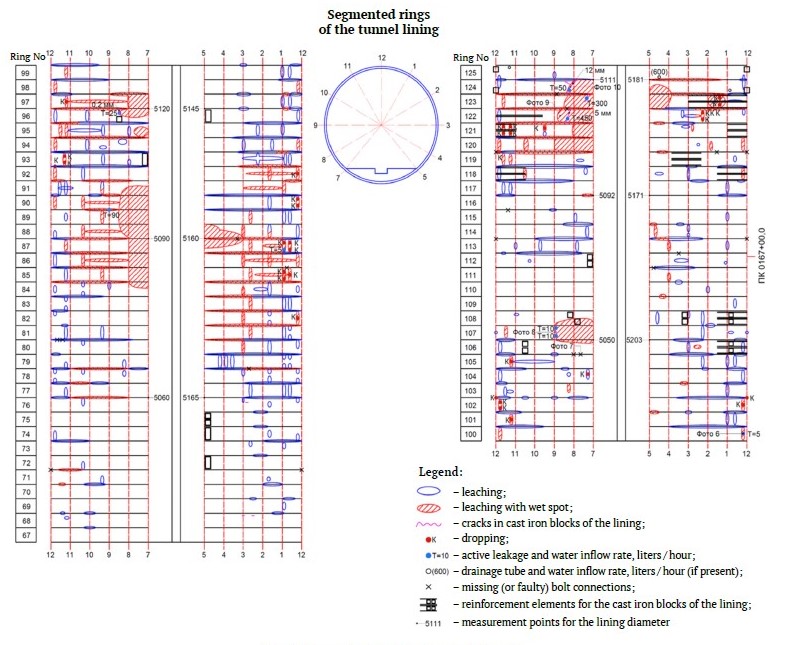

Based on the results of the in-situ inspection, a defect map of the tunnel lining was created, with a fragment shown in Fig. 9.

Fig. 9. Tunnel lining defect map, obtained from the in-situ inspection of operational facilities (PK167 + 00.0)

Conclusions

The identified changes in the tunnel lining structure showed that 60% of the leaks are concentrated around the locations of construction joints. The tubbing itself also begins to filter water, exacerbating leaching processes, which leads to the appearance of wet spots. Since the surrounding rock mass consists of weak, unstable soils, the washout of soil into the tunnel space could result in subsidence, which, in turn, would cause deformations and settlement of the ground surface. Consequently, there is a marked reduction in the environmental and geotechnical safety level of the metro running tunnel.

The obtained research results, including the analysis of defects in tunnel structures caused by hydrogeological factors, form the basis for further determination of acceptable risks and the development of methods for ensuring the environmentally safe operation of urban metro transport tunnels.

Future plans include the creation of a geomechanical impact model on metro structures. The modeling will allow for the evaluation of how geomechanical phenomena such as karst processes, ground surface subsidence, soil heaving, and changes in the groundwater regime contribute to the stress-strain state of the prefabricated lining of metro running tunnels. The modeling is planned to be conducted using a three-dimensional numerical method in the ANSYS Workbench software package. Comparing the results of the modeling with experimental data will allow for an assessment of the reliability of the proposed methodology.

References

1. Kulikova E. Yu., Balovtsev S. V., Skopintseva O. V. Complex estimation of geotechnical risks in mine and underground construction. Sustainable Development of Mountain Territories. 2023;15(1):7–16. (In Russ.) https://doi.org/10.21177/1998-4502-2023-15-1-7-16

2. Kulikova Е. Yu. Safety and risk management in underground construction as a complex information process. Mining Informational and Analytical Bulletin. 2021;(2–1):134-143. (In Russ.) https://doi.org/10.25018/0236-1493-2021-21-0-134-143

3. He X. C., Xu Y. S., Shen S. L., Zhou A. N. Geological environment problems during metro shield tunnelling in Shenzhen, China. Arabian Journal of Geosciences. 2020;13(2):87. https://doi.org/10.1007/s12517-020-5071-z

4. Xu Y. S., Shen J. S., Zhou A. N., Arulrajah A. Geological and hydrogeological environment with geohazards during underground construction in Hangzhou: a review. Arabian Journal of Geosciences. 2018;11:544. https://doi.org/10.1007/s12517-018-3894-7

5. Lin X.-T., Chen R.-P., Wu H.-N., Cheng H.-Zh. Deformation behaviors of existing tunnels caused by shield tunneling undercrossing with oblique angle. Tunnelling and Underground Space Technology. 2019;89:78–90. https://doi.org/10.1016/j.tust.2019.03.021

6. Merisalu J., Sundell J., Rosén L. Probabilistic cost-benefit analysis for mitigating hydrogeological risks in underground construction. Tunnelling and Underground Space Technology. 2023;131(7):104815. https://doi.org/10.1016/j.tust.2022.104815

7. Konyukhov D. S. Criteria analysis of modern technologies of underground construction. Geotekhnika. 2021;(1):40–55. (In Russ.)

8. Konyukhov D. S. Analysis of mechanized tunneling parameters to determine the overcutting characteristics. Mining Science and Technology (Russia). 2022;7(1):49–56. https://doi.org/10.17073/2500-0632-2022-1-49-56

9. Lebedev M. O. Choosing a calculation method for stress-strain of supports and lining of transport tunnels. In: 16 th World Conference of the Associated Research Centers for the Urban Underground Space (ACUUS 2018). 5–7 November 2018, Hong Kong. Pp. 678–687.

10. Bourget A. P. F., Chiriotti E., Patrinieri E. Evolution of risk management during an underground project’s life cycle. In: Peila D., Viggiani G., Celestino T. (Eds). Tunnels and Underground Cities: Engineering and Innovation meet Archaeology, Architecture and Art. London: CRC Press; 2019. Pp. 4375–4385. https://doi.org/10.1201/9780429424441-463

11. Mahdi S., Gastebled O., Ningre H., Senechal M. Grand Paris Express, Line 15 East – predictive damage analysis combining continuous settlement trough modeling, risk management, automated vulnerability checks and visualization in GIS. In: Peila D., Viggiani G., Celestino T. (Eds). Tunnels and Underground Cities: Engineering and Innovation meet Archaeology, Architecture and Art. London: CRC Press; 2019. Pp. 5855–5864. https://doi.org/10.1201/9780429424441-619

12. Hongjun W. Earth human settlement ecosystem and underground space research. Procedia Engineering. 2016;165:765–781. https://doi.org/10.1016/j.proeng.2016.11.774

13. Garber V. A. Abnormal situations at underground transport facilities. Podzemnye Gorizonty. 2018; (16):20–25. (In Russ.)

14. Kulikova E. Yu. Methodical principles for improving the ecological and technological reliability of urban underground structures. Mining Informational and Analytical Bulletin. 2020;(6–1):176–185. (In Russ.) https://doi.org/10.25018/0236-1493-2020-61-0-176-185

15. Kulikova E. Yu., Balovtsev S. V. Risk control system for the construction of urban underground structures. In: IOP Conference Series: Materials Science and Engineering. 2020;962(4):042020. https://doi.org/10.1088/1757-899X/962/4/042020

16. Kim D. Y., Farrokh E., Song M. K., Hyun K. S. Cutting tool wear evaluation for soft ground TBMs. In: Proceeding of the World Tunnel Congress 2017. Surface challenges – Underground solutions. 9–15 th June 2017, Bergen, Norway. Bergen; 2017.

17. Potapova E. V. Typology of metro structures for the tasks of geotechnical risk classification. Mining Science and Technology (Russia). 2021;6(1):52–60. (In Russ.) https://doi.org/10.17073/2500-0632-2021-1-52-60

18. Kuepferle J., Roetteger A., Thesen W., Alber M. Wear prediction for soft-ground tunneling tools – a new approach regarding the dominant influencing factors in the tribological system of tunneling tools. In: Proceeding of the World Tunnel Congress 2017. Surface challenges – Underground solutions. 9–15 th June 2017, Bergen, Norway. Bergen; 2017.

Review

For citations:

Zhukov S.A. Substantiation of environmental safety in metro facility operations considering hydrogeological risks. Mining Science and Technology (Russia). 2024;9(3):283-291. https://doi.org/10.17073/2500-0632-2024-04-259