Scroll to:

Mineral resource base of Russia’s cobalt: current state and development prospects

https://doi.org/10.17073/2500-0632-2025-02-368

Abstract

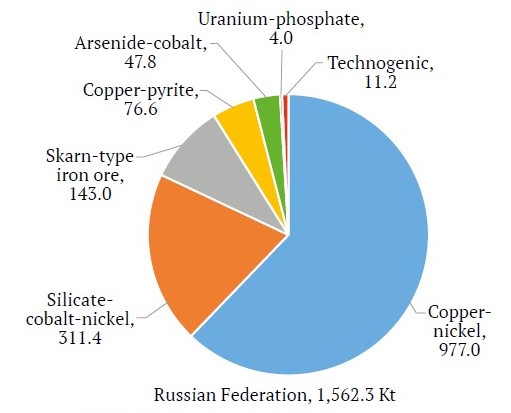

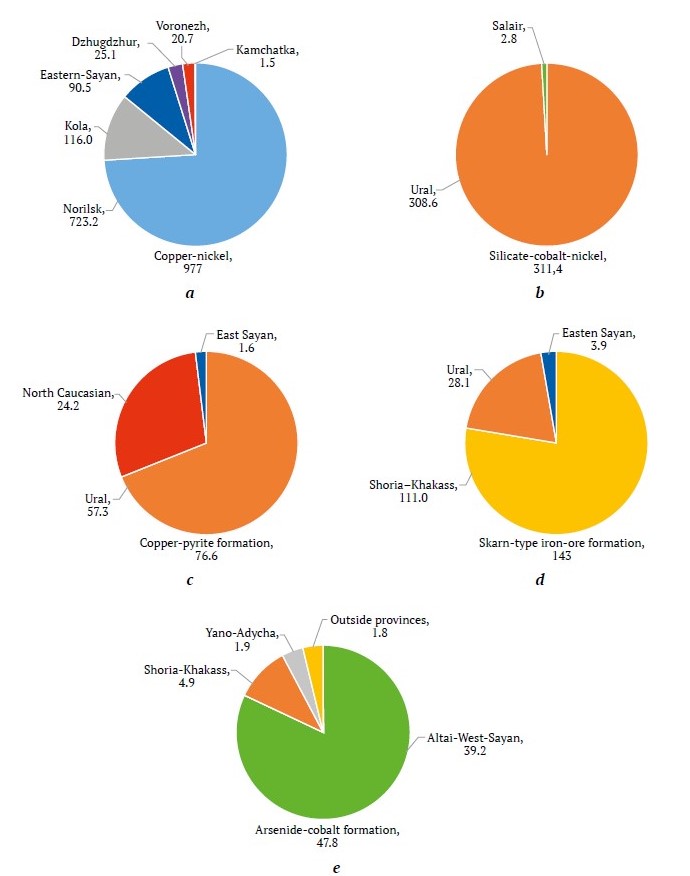

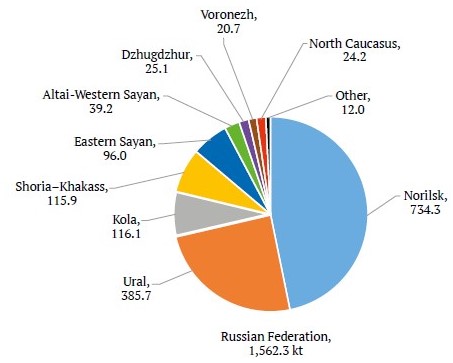

The relevance of this study stems from the need to obtain a comprehensive picture of the state of the cobalt mineral resource base of the Russian Federation. Objective: to examine the current state of Russia’s cobalt mineral resource base, the spatial distribution of cobalt deposits by ore formation types and within ore provinces, and the prospects for national cobalt production. Methods: statistical, graphical, and logical analysis. Results: a consolidated schematic map of Russia is presented, featuring 25 cobalt-bearing provinces and a sample of 150 of the most significant cobalt deposits across various ore formations, along with prospective sites and areas. Key characteristics are provided for the main ore formations hosting cobalt deposits in Russia, as well as for cobalt-bearing provinces and deposits outside these provinces. In Russia, cobalt is extracted as a by-product from sulfide copper-nickel ores (9.2 Kt in 2022). As of January 1, 2023, Russia’s balance reserves of cobalt totaled 1,562.3 Kt. The largest volumes of cobalt reserves are associated with the copper-nickel formation (62.5%) and the silicate-cobalt-nickel formation (19.9%), with the remaining 17.6% distributed among all other ore formations. By province, the Norilsk province accounts for 47.0% of Russia’s cobalt reserves, the Ural province – 24.7%, the Kola and Shoria-Khakass provinces – 7.4% each, the Easten Sayan province – 6.1%, and all other provinces – 7.7%. The Russian Federation has been allocated exploration areas on the international seabed in the Pacific Ocean, where geological surveys are underway in the cobalt-rich ferromanganese crust formation of the Magellan Mountains (resources of 110 Kt Co, with 0.50–0.61% Co) and in the ferromanganese nodule formation of the Clarion-Clipperton ore field (resources of 985 Kt Co, with 0.22–0.29% Co). Despite a substantial base of prepared cobalt reserves, Russia lacks a systematic accounting of forecast cobalt resources, complicating the planning of geological exploration for cobalt. A systematic review of existing geological and geochemical data on known occurrences and points of cobalt mineralization is proposed, with the aim of assessing forecast resources using a unified methodology and producing a consolidated forecast resource balance for cobalt in Russia. For deposits of the silicate-cobalt-nickel formation, where previous assessments were based on maximizing nickel reserves, a reassessment is proposed with 3D special modeling of cobalt distribution as the primary ore component. Such deposits can then be managed specifically for cobalt production. Advancements in underground and heap leaching technologies, as well as bioleaching of cobalt-bearing ores, will enable the development of cobalt deposits with low-grade ores and small reserves, as well as the reprocessing of technogenic materials derived from beneficiation and metallurgical processes. The most promising targets for cobalt extraction using in-situ leaching, heap leaching, and bioleaching technologies are the deposits of the silicate-cobalt-nickel formation.

Keywords

For citations:

Boyarko G.Yu., Bolsunovskaya L.M. Mineral resource base of Russia’s cobalt: current state and development prospects. Mining Science and Technology (Russia). 2025;10(2):118-147. https://doi.org/10.17073/2500-0632-2025-02-368

Mineral resource base of Russia’s cobalt: current state and development prospects

Introduction

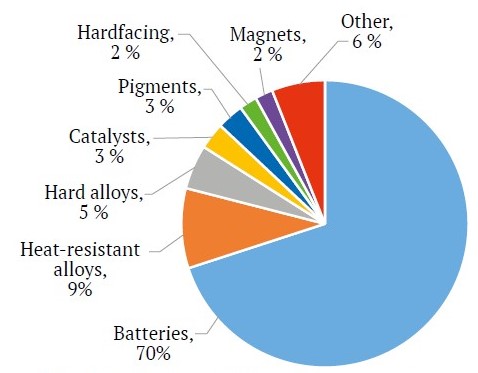

Cobalt is used in a wide range of applications: in the cathodes and anodes of electric batteries and accumulators (as cobalt oxide), in oxidation catalysts (cobalt acetates, carboxylates, and carbonyls), in blue pigments and dyes (cobalt phosphates and aluminates), in heat-resistant alloys (e.g., Vitallium, cermets), hard alloys (e.g., Stellite, Pobedit), and magnetic alloys (e.g., Alnico), as well as in strengthening powder coatings and alloy compositions. Global cobalt consumption reached 187 Kt in 2022 [1] and continues to rise due to growing demand for rechargeable batteries (Fig. 1). The leading cobalt-producing countries are the Democratic Republic of the Congo (76% of global production), Indonesia (9.7%), Russia (3.0%), Australia (2.0%), and the Philippines (1.9%). The cobalt market is considered high-risk due to the fact that primary cobalt deposits are extremely rare, and the cobalt available on the market is typically a by-product of the mining of copper, copper-nickel sulfide, and silicate-nickel deposits. As a result, the supply of cobalt is highly inelastic, which has led to price crises and sharp spikes in cobalt prices, such as in 1978 (due to the war in Zaire, now the Democratic Republic of the Congo) and in 2017 (due to a surge in demand for energy storage systems) [2, 3].

Fig. 1. Distribution of global cobalt consumption in 2022 [1]

In Russia, cobalt is classified as a strategic mineral resource, although its production volumes are not critical, as they significantly exceed domestic demand. Nevertheless, the issue of limited controllability over cobalt supply volumes does exist in Russia, as cobalt is extracted as a by-product from ores of the copper-nickel sulfide formation [4]. Despite Russia’s considerable accounted balance reserves of cobalt, planning to increase production in the context of the growing lithium-ion battery industry [5] will be challenging for new development projects targeting complex copper-nickel, silicate-nickel, iron ore, and sulfide (pyrite) deposits, where cobalt is of secondary importance. It is also worth noting the lack of a consolidated balance of forecast cobalt resources across the Russian Federation, as well as the inconsistent methodologies used by different authors to estimate cobalt reserves and resources at individual deposits. Given global trends of rising cobalt consumption – and the potential for a sharp increase in domestic demand – it is necessary to assess the capabilities of Russia’s cobalt mineral resource base, which is the aim of the present review.

Research methodology

To assess the state of Russia’s mineral resource base of cobalt, data were compiled on reserves and forecast resources of cobalt and cobalt-bearing deposits as of January 1, 2023. Sources included state reports of the Ministry of Natural Resources and Environment of the Russian Federation1, informational reports on the status and prospects of mineral resource use2, state cadastral passports of deposits and mineral occurrences in Russia3 and published open-access literature on cobalt deposits and resources. All figures on cobalt reserves, resources, and production are given in metric tons of contained cobalt (100% Co). A general schematic map of Russia was compiled, showing cobalt-ore provinces and a selection of the most significant cobalt deposits from various ore formations, along with promising targets and areas for geological exploration. The study also examined the potential for cobalt mining development using innovative extraction and processing technologies for cobaltbearing ores [6]. An analysis was carried out on the status of balance reserves by ore formation and by cobalt-ore province.

1 State report on the status and use of the mineral resources of the Russian Federation in 2021. Ministry of Natural Resources and Environment of the Russian Federation; 2022. 626 p. URL: https://www.mnr.gov.ru/docs/gosudarstvennye_doklady/o_sostoyanii_i_ispolzovanii_mineralno_syrevykh_resursov_rossiyskoy_federatsii/

2 Information on the status and prospects of use of the mineral resource base in the regions of the Russian Federation (as of 01.01.2022). St. Petersburg: VSEGEI, State Assignment No. 049-00018-22-01 of January 14, 2022; 2022. URL: http://atlaspacket.vsegei.ru/?v=msb2021#91474d2e700eb6c90

3 Passports of cobalt deposits. Russian Federal Geological Fund. The unified fund of geological information about the subsurface. The register of primary and interpreted data; 2023. 2023. URL: https://efgi.ru/

State of the cobalt mineral resource base in Russia

Russia ranks 6th globally in cobalt reserves, following the Democratic Republic of the Congo, Australia, Indonesia, Cuba, and the Philippines. It holds 3rd place in primary cobalt extraction, after the Democratic Republic of the Congo and Indonesia, and 6th place in refined cobalt production, after China, the United States, Finland, Canada, Japan, and Norway [4, 7]. Russia’s cobalt mineral resource base is primarily composed of deposits belonging to two key geological-industrial types: the copper-nickel sulfide type and the silicate-cobalt-nickel type. At present, cobalt is extracted exclusively as a by-product from copper-nickel sulfide ores. Mining at silicate-cobalt-nickel deposits has been suspended since 2012, and at arsenide-cobalt deposits since 1991. Balance reserves of cobalt are also recorded at currently developed copper-pyrite and skarn-type iron ore deposits, but cobalt is not extracted from these due to technological and economic limitations.

Based on the compiled data, the following materials were developed:

- a general map of Russia’s cobalt-ore provinces, major deposits, and cobalt occurrences (Fig. 2);

- charts presenting cobalt reserves by ore formation (as of 2021) (Fig. 3) and by province (Fig. 8);

- charts showing cobalt reserves by province within individual ore formations (Fig. 4).

The following sections provide an overview of the cobalt-bearing ore formations identified within the Russian Federation, as well as the corresponding cobalt-ore provinces.

Fig. 2. Cobalt-ore provinces, deposits, and occurrences by geological and technological type:

1 – cobalt-ore provinces; 2–13 – geological and technological types of cobalt deposits (a – reserves + resources over 10,000 t Co; b – 1,000–10,000 t Co): 2 – copper-nickel cobalt-bearing, 3 – low-sulfide platinum group element (PGE) cobalt-bearing, 4 – silicate cobalt-nickel, 5 – pyrite-type cobalt-bearing, 6 – skarn-type iron ore cobalt-bearing, 7 – titanomagnetite-type cobalt-bearing, 8–12 – arsenide-cobalt (8 – cobalt-nickel, 9 – bismuth-cobalt, 10 – primary arsenide-cobalt, 11 – gold-silver, 12 – tin-tungsten), 13 – uranium-type cobalt-bearing, 14 – manganese-ore cobalt-bearing; 15 – cobalt-iron-manganese crusts and nodules; 16 – technogenic cobalt-ore provinces: I – North Caucasian, II – Ergeninsky, III – Voronezh, IV – Baltic, V – Karelian, VI – Kola, VII – Ural, VIII – Norilsk, IX – Salair, X – Shoria-Khakass, XI – Altai–Western Sayan, XII – Eastern Sayan, XIII – North Baikal, XIV – Dzhugdzhur, XV – Yana–Adycha, XVI – Seymchan, XVII – Koryak, XVIII – Kamchatka. Cobalt deposits and occurrences: 1–24 – cobalt–copper–nickel (1 – Elan, 2 – Pedrorechenskoe, 3 – Semchozerskoe, 4 – Voloshovskoe, 5 – Zhdanovskoe, 6 – Tundrovoe, 7 – Sopchuayvench, 8 – Poaz, 9 – Nyud-Moroshkovoe, 10 – Nittis-Kumuzhya-Travyanaya, 11 – Oktyabrskoe-Cu-Ni, 12 – Talnakhskoe, 13 – Norilsk-1, 14 – Maslovskoe, 15 – Chernogorskoe, 16 – Vologochanskoe, 17 – Kingash, 18 – Verkhnekingash, 19 – Tokty-Oy, 20 – Chaya, 21 – Kun-Manie, 22 – Ariadnoe, 23 – Dukukskoe, 24 – Shanuch); 25–32 – low-sulfide platinum group element (PGE) cobalt-bearing (25 – Shalozerskoe, 26 – Viksha, 27 – Kievey, 28 – Monchetundrovskoe, 29 – Pyatirechenskoe, 30 – Mainitskaya, 31 – Valaginsko-Karaginskaya, 32 – Snezhnoye); 33–48 – silicate cobalt-nickel (33 – Buruktal, 34 – Novokievskoe, 35 – Sakharinskoe, 36 – Elizavetinskoe, 37 – Serovskoe, 38 – Yareney, 39 – Belininskoe, 40 – Aleksandrovskoe); 41–49 – pyrite-type cobalt-bearing (41 – Khudesskoe, 42 – Kizil-Dere, 43 – Gaiskoe, 44 – Dergamysh, 45 – Ivanovskoe, 46 – Saumskoe, 47 – Pyshminsko-Klyuchevskoye, 48 – Savinskoe, 49 – Degdenreken); 50–59 – skarn-type iron ore cobalt-bearing (50 – Techenskoe, 51 – Peschanskoe, 52 – Chesnokovskoe, 53 – Tashtagolskoe, 54 – Anzasskoe, 55 – Abakanskoe, 56 – Volkovsky Fe, 57 – Izygskoye, 58 – Oktyabrskoe-Fe, 59 – Taezhnoe); 60–62 – titanomagnetite-type cobalt-bearing (60 – Magazin-Musyur, 61 – Volkovsky Fe-V-Cu, 62 – Chineyskoe); 63–77 – arsenide-cobalt: 63–67 – cobalt-nickel (63 – Bazasskoe, 64 – Butrakhtinskoe, 65 – Atbashi, 66 – Kuruozek, 67 – Khovu-Aksy), 68–73 – bismuth-cobalt (68 – Yantau, 69 – Karakul, 70 – Perevalnoe, 71 – Uronaysky, 72 – Belogorskoe, 73 – Verkhne-Seimchanskoe, Vetrovoe), 74 – Haradzhul (primary arsenide-cobalt), 75–76 – cobalt-bearing gold-silver (75 – Orekhozero, 76 – Podgornoe), 77 – Alys-Khaya (cobalt-bearing tin-tungsten); 78–80 – uranium-type cobalt-bearing (78 – Bogorodskoe, 79 – Shargadykskoe, 80 – Kummolovskoe); 81–86 – manganese-ore cobalt-bearing (81 – Tetrauk, Zianchurinskoe, 82 – Matyuzhikha, 83 – Selezenskoe, 84 – Mazulskoe, Bityatskoe, Butkeevskoe-2, Tsepelyaevskoe, 85 – Kamenskoe, Rudnoe, Zapadny, 86 – Yuzhno-Khinganskoe, Bidzhanskoe); 87 – Pavlovskoe occurrence of continental cobalt–ferromanganese crusts; 88–89 – technogenic deposits (88 – dumps of the Allarechensky copper-nickel deposit, 89 – dumps of the Allarechensky copper-nickel deposit)

Fig. 3. Distribution of cobalt balance reserves in the Russian Federation by cobalt ore formation (as of 2021)

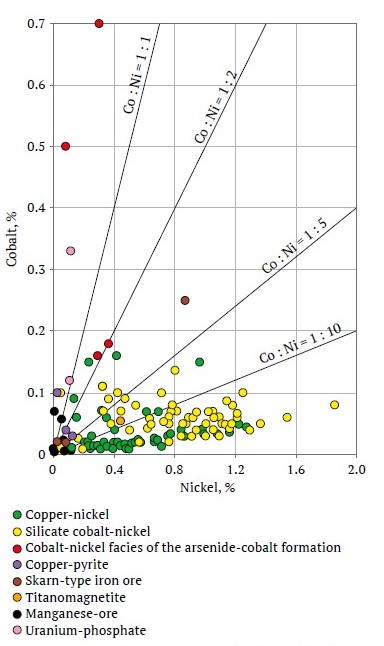

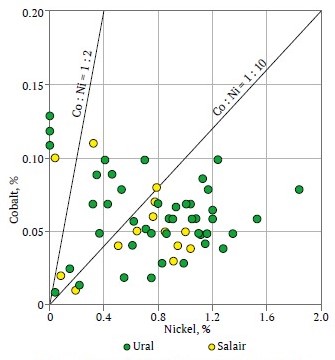

Fig. 4. Scatter plot of average cobalt and nickel grades in deposits by ore formation

Cobalt ore formations

Cobalt-bearing ore formations are classified into two groups: (1) primary cobalt formations, where cobalt is the principal (most valuable) mineral component, and (2) cobalt-associated formations, where cobalt occurs as a by-product. The first group includes the endogenic arsenide-cobalt formation and the biogenic formation of cobalt-rich crusts on oceanic seamounts. The second group comprises cobalt-associated endogenic formations such as the copper-nickel sulfide, low-sulfide platinum-group element (PGE), copper-pyrite, skarn iron-ore, vanadium-titanomagnetite, uranium-phosphate, and manganese-ore formations, as well as the exogenic silicate–cobalt–nickel formation. In the course of mining operations across these various formations – particularly under selective mining conditions and in waste management systems – technogenic cobalt-bearing deposits are also formed, giving rise to the technogenic formation.

At present, only complex copper–nickel formation deposits are being actively developed for cobalt. Previously, deposits of the silicate cobalt–nickel formation were exploited in the Ural, and arsenide–cobalt formation deposits in the Altai–Western Sayan and Seimchan provinces.

The currently developed cobalt-bearing copper–nickel and silicate cobalt–nickel formation deposits account for a combined 82.5% of Russia’s total economic cobalt reserves, whereas deposits of the primary cobalt (arsenide–cobalt) formation that were exploited in the past contribute only 3.0% (see Fig. 3). Consequently, due to the limited volume of proven cobalt reserves, it is extremely challenging to systematically plan for an increase in domestic cobalt supply.

An analysis of the spatial distribution of deposits with varying compositions across most endogenic cobalt-bearing formations indicates their spatial association with basic–ultrabasic rock complexes, with the exception of deposits and occurrences in the Seimchan and Yano–Odychan provinces. However, even in these regions, the presence of such complexes at depth is considered possible, due to the presence of siderophile elements (Co, Ni, Cr) in the ore bodies [8]. In virtually all cobalt and cobalt-bearing formations, cobalt is accompanied by nickel, often in considerably high concentrations (see Fig. 4).

In ophiolitic complexes, cobalt is concentrated in pentlandite (up to 3% Co), pyrrhotite (up to 0.9% Co), and pyrite (up to 1.8 % Co), while the majority of rock-bound cobalt occurs as a minor admixture in olivine (0.008 % Co), pyroxenes, and amphiboles (up to 0.004 % Co) [9, 10]. During hydrothermal alteration of basic and ultrabasic rocks–particularly in the course of endogenic serpentinization of olivine–cobalt readily enters solution and contributes to the formation of new ore parageneses. These include cobalt-bearing pyrite in the copper–pyrite formation [11]; arsenide and sulfoarsenide mineralization in the arsenide–cobalt formation [9, 10]; and cobalt-pyrite and cobaltite mineralization in the skarn-type iron ore formation [12] and vanadium–titanomagnetite formation.

Under supergene conditions, weathering of ophiolitic rocks leads to serpentinization of silicates and oxidation of sulfides, resulting in the mobilization of both cobalt and nickel. This process forms ore bodies of the silicate–cobalt–nickel formation, with cobalt accumulating in nontronite and garnierite, as well as being adsorbed on goethite, asbolane, and other manganese oxides and hydroxides [13, 14]. With further infiltration, cobalt precipitates at chemical barriers formed by diagenetic sulfides in the uranium–phosphate formation [35] and in manganese-ore formation bodies [9].

According to Co : Ni ratios (Table 1), the highest values are observed in the manganese-ore, copper–pyrite, uranium–phosphate, and arsenide–cobalt formations. In these, the primary cobalt concentrators are, respectively: manganese oxides, pyrite, organic matter, and cobalt arsenides and sulfoarsenides. The lowest Co : Ni ratios are found in copper–nickel formation deposits, where pentlandite serves as the main cobalt-bearing mineral, and in the silicate–cobalt–nickel formation, where nontronite and garnierite are the main cobalt and nickel carriers.

Table 1

Cobalt-to-nickel ratios by cobalt ore formation*

Formation | Co : Ni ratio |

Copper–nickel | 0.088* |

Silicate cobalt–nickel | 0.089 |

Iron ore | 0.51 |

Titanomagnetite | 0.315 |

Arsenide–cobalt | 2.08 |

Copper–pyrite | 2.1 |

Uranium–phosphate | 1.92 |

Manganese-ore | 6.92 |

* – the numerator shows the average value, the denominator shows the range of values.

In ophiolitic complexes, cobalt is concentrated in pentlandite (up to 3% Co), pyrrhotite (up to 0.9% Co), and pyrite (up to 1.8 % Co), while the majority of rock-bound cobalt occurs as a minor admixture in olivine (0.008 % Co), pyroxenes, and amphiboles (up to 0.004 % Co) [9, 10]. During hydrothermal alteration of basic and ultrabasic rocks–particularly in the course of endogenic serpentinization of olivine–cobalt readily enters solution and contributes to the formation of new ore parageneses. These include cobalt-bearing pyrite in the copper–pyrite formation [11]; arsenide and sulfoarsenide mineralization in the arsenide–cobalt formation [9, 10]; and cobalt-pyrite and cobaltite mineralization in the skarn-type iron ore formation [12] and vanadium–titanomagnetite formation.

Under supergene conditions, weathering of ophiolitic rocks leads to serpentinization of silicates and oxidation of sulfides, resulting in the mobilization of both cobalt and nickel. This process forms ore bodies of the silicate–cobalt–nickel formation, with cobalt accumulating in nontronite and garnierite, as well as being adsorbed on goethite, asbolane, and other manganese oxides and hydroxides [13, 14]. With further infiltration, cobalt precipitates at chemical barriers formed by diagenetic sulfides in the uranium–phosphate formation [35] and in manganese-ore formation bodies [9].

According to Co : Ni ratios (Table 1), the highest values are observed in the manganese-ore, copper–pyrite, uranium–phosphate, and arsenide–cobalt formations. In these, the primary cobalt concentrators are, respectively: manganese oxides, pyrite, organic matter, and cobalt arsenides and sulfoarsenides. The lowest Co : Ni ratios are found in copper–nickel formation deposits, where pentlandite serves as the main cobalt-bearing mineral, and in the silicate–cobalt–nickel formation, where nontronite and garnierite are the main cobalt and nickel carriers.

The copper-nickel formation is currently the primary source of cobalt in Russia and is represented by a number of producing and explored deposits. Sulfide copper-nickel deposits are spatially and genetically associated with mafic and ultramafic igneous massifs located along platform margins (Norilsk-type), within cratons (Pechenga-type), and in the central parts of fold belts [15]. The main commercial products of these deposits are copper and nickel, while cobalt, platinum-group elements, selenium, and tellurium are extracted as by-products [16].

According to officially recorded reserves, the copper–nickel formation accounts for 62.5% of Russia’s balance cobalt reserves (977 kt of Co)4 (see Fig. 2), with average cobalt grades in the deposits reaching up to 0.19%. In total, 73 copper–nickel deposits and occurrences with reported cobalt reserves or resources are known in Russia, including 50 containing over 1 kt and 25 with more than 10 kt of cobalt. Mining of copper–nickel ores and extraction of cobalt from them is carried out at deposits in the Norilsk and Kola provinces (operated by PJSC MMC Norilsk Nickel), as well as in the Kamchatka province (JSC SPC Geotekhnologiya). Copper–nickel deposits containing cobalt are currently being prepared for development in the Eastern Sayan, Dzhugdzhur, and Voronezh provinces (see Fig. 5, a). In 2022, 12,651 t of cobalt was produced in Russia from cobalt–copper–nickel formation ores, the majority of which was exported5.

Fig. 5. Distribution of cobalt balance reserves by individual cobalt ore formations across Russian provinces as of 2021:

a – copper–nickel; b– silicate–cobalt–nickel; c – copper–pyrite; d – skarn-type iron ore; e – arsenide-cobalt

The main cobalt-bearing mineral in copper-nickel ore deposits is pentlandite, which contains between 0.1 and 3.0 % cobalt, in which cobalt isomorphically replaces nickel and iron. In the ores of some sulfide copper–nickel deposits, cobalt-bearing pyrite is also present, with cobalt grade up to 1.8 %.

Adjacent to the copper-nickel formation is the low-sulfide platinum-group element (PGE) formation, in which dispersed sulfide mineralization contains only minor copper–nickel components, and the primary economic value lies in PGE mineralization [17–19]. These deposits and occurrences also contain associated cobalt, with average grades reaching up to 0.07%. PGE deposits and occurrences are known in the Kola, Karelian, Ural, and Chukotka–Koryak provinces.

The silicate-cobalt-nickel formation represents the products of supergene weathering of serpentinized ultramafic and mafic rocks, including both residual and infiltration types [13]. Serpentinite massifs with cobalt-bearing nickel-rich weathering crusts are known within the Ural and Salair provinces.

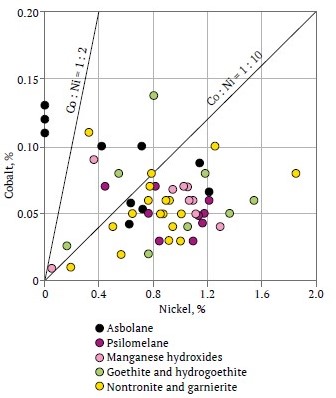

At deposits of the silicate cobalt–nickel formation, the distribution pattern shows generally lower Co : Ni ratios compared to deposits of the copper–nickel formation (see Fig. 4), indicating relative cobalt enrichment in weathering crusts in comparison to nickel. However, within the Co : Ni ratio distribution across silicate cobalt–nickel formation deposits, no significant differences are observed between the deposits of the Ural and Salair provinces (Fig. 6).

Fig. 6. Average cobalt and nickel grades in deposits of the silicate–cobalt–nickel formation by province

Fig. 7. Average cobalt and nickel grades in deposits of the silicate–cobalt–nickel formation by cobalt-bearing minerals

Nickel tends to accumulate in the middle part of the weathering profile within the nontronite zone, primarily as nickel-bearing hydrosilicates (garnierite, revdinskite, nepouite, etc.), whereas cobalt is typically concentrated in the lower part of the profile, in the ocher zone, together with manganese, occurring as cobalt-containing manganese oxides and hydroxides (asbolane, cobaltian manganite, cobalt-rich psilomelane). As a result, the spatial distribution patterns (geometry) of nickel and cobalt halos may not coincide, forming localized enrichment zones of either nickel or cobalt. Given that geological exploration is primarily focused on nickel, cobalt resources may be underestimated when its mineralization occurs outside the assessment contour of the primary ore component.

The highest cobalt concentrations are observed when it is sorbed onto asbolane (according to the literature, up to 32% Co [9]); at the Kaincha occurrence in the Salair province, values of up to 10% Co have been reported. In the Ural province, the Elizavetinskaya group of deposits {No. 36} is classified as asbolane-bearing. At sites where asbolane is identified as the principal cobalt concentrator (see Fig. 7, Table 2), the highest average cobalt contents are recorded. Cobalt-bearing goethite and hydrogoethite are sometimes found accumulating alongside asbolane [14]. Nontronite and garnierite occur predominantly in the central nontronite zone of the weathering crust, where nickel accumulates, typically at lower cobalt concentrations. However, in some cases, linear weathering zones host unusual garnierite veins with high contents of both nickel and cobalt. These may have been enriched through late-stage hydrothermal alteration of the weathering crust material [20, 21].

Table 2

Cobalt-nickel ratios by cobalt-bearing minerals in deposits and occurrences of the silicate–cobalt–nickel formation

Main cobalt-bearing mineral | Co : Ni ratio |

Asbolane | 0.105* |

Goethite | 0.088 |

Manganese Hydroxides | 0.096 |

Garnierite | 0.053 |

Nontronite | 0.079 |

Psilomelane | 0.062 |

* – the numerator shows the average value, the denominator shows the range of values.

According to officially recorded reserves, the silicate–cobalt–nickel formation accounts for 19.9% of Russia’s cobalt balance reserves (311.4 Kt of Co)6 (see Fig. 3), with average cobalt grades in deposits reaching up to 0.11%. In total, 59 deposits and occurrences of silicate–cobalt–nickel ores with recorded cobalt reserves or resources are known in Russia, including 33 with more than 1 Kt and 6 with over 10 Kt of cobalt. Silicate–cobalt–nickel ore extraction was previously carried out at deposits in the Ural province by Southern Urals Nickel Plant PJSC (Kombinat Yuzhuralnikel) (until 2013). The occurrences of silicate–cobalt–nickel ores identified through geolo|gical exploration in the Salair province have not yet been prepared for development (see Fig. 5, b).

The copper–pyrite formation represents a mixed group of deposits of volcanogenic hydrothermal–sedimentary and hydrothermal–metasomatic origin, occurring as bed- and lens-shaped accumulations of consolidated sulfide ores, with pyrite and copper sulfides playing the leading role [22, 23]. The formation of cobalt-bearing copper–pyrite deposits is primarily driven by the release of cobalt from the olivine mineral matrix during hydrothermal serpentinization of ultramafic rocks, followed by its precipitation onto sulfides [11]. Most copper–pyrite deposits are located in the Ural province, where they are mined primarily for copper and zinc; some are also found in the North Caucasus province. Many copper–pyrite deposits in both the Ural and North Caucasus provinces are characterized by cobalt as a by-product mineralization [24, 25] (see Fig. 5, c).

Two types of cobalt-bearing pyrite–copper deposits are distinguished: the so-called Cyprus-type sulfur-copper–pyrite deposits and Ural-type copper–zinc pyrite deposits [26]. The Cyprus type is characterized by cobalt occurring in the mineral form of cobaltite, and to a lesser extent as an impurity in pyrite and chalcopyrite. These deposits are generally small, occasionally medium in size. Most of the Cyprus-type sulfur–copper–pyrite deposits (some of which were mined for cobalt) have now been depleted. In contrast, cobalt in Ural-type deposits is predominantly found in cobalt-bearing pyrite, and less frequently in cobalt-bearing pyrrhotite. Copper–zinc pyrite deposits of the Ural type are notable for their significant reserves of zinc and copper, and some also contain cobalt as a by-product, which is primarily associated with the pyrite ores rather than the copper–zinc ores. The cobalt grade in copper concentrates from Ural deposits reaches 0.005 %, and in zinc concentrates, 0.003%. As a result, at the currently operating Ural-type copper–zinc pyrite deposits, cobalt is not extracted during copper and zinc production and instead accumulates in pyrite-rich tailings from the beneficiation process.

The cobalt-bearing copper–pyrite formation accounts for 4.9% of Russia’s officially recorded cobalt balance reserves (76.5 Kt of Co)7 (see Fig. 3), with average cobalt grades in deposits reaching up to 0.07%. In total, 28 deposits and occurrences of cobalt-bearing copper–pyrite ores with recorded cobalt reserves or resources are known in Russia, including 9 with more than 1 Kt and 2 with over 10 Kt of cobalt. Cobalt is not extracted from the mined copper and zinc ores due to the lack of economic viability of extracting cobalt-bearing pyrite concentrates.

The cobalt-bearing skarn-type iron ore formation is represented by contact-metasomatic deposits occurring at the interface between intrusive rocks ranging from mafic to felsic composition and limestone sedimentary rocks. Iron-rich skarn formations serve as the substrate for superimposed sulfide mineralization containing cobalt minerals [12, 27]. The sulfide mineralization consists of pyrite and copper minerals (chalcopyrite, bornite). Cobalt occurs in cobalt-bearing pyrite, occasionally as cobaltite, and sometimes in tetrahedrite-group minerals (fahlores).

A total of 21 cobalt-bearing skarn-type iron ore deposits and occurrences are known in the Russian Federation, where cobalt reserves or resources have been identified. Among them, 14 objects contain more than 1 kt, and 6 objects contain more than 10 kt of cobalt, with average cobalt grades in individual deposits reaching up to 0.18%. These deposits are located in the Ural and Shoria-Khakass provinces (see Fig. 5, d), as well as outside the delineated provinces – including the Oktyabrskoe-Fe deposit in Irkutsk Region {No. 58} (reserves of 6 kt Co, 0.028% Co), the Tayozhnoye boron–iron ore deposit in the Republic of Sakha (Yakutia) {No. 59}, which contains blocks enriched in cobalt mineralization (11.6 kt Co, 0.11% Co) [28], and the Chesnokovskoe occurrence in Altai Territory {No. 52} (1 kt Co, 0.02% Co) [29]. Cobalt is not extracted from mined high-grade iron ores due to the absence of a sulfide phase separation process during beneficiation. However, there have been successful attempts to extract cobalt-bearing pyrite concentrate from the magnetic separation tailings of iron ores from the Shoria-Khakass province at the Abagur beneficiation plant [30].

Cobalt-bearing skarn-type iron ore formations account for 9.0% of Russia’s total economic cobalt reserves (141 kt of Co)8, (see Fig. 3).

The vanadium-bearing titanomagnetite formation is paragenetically related to the cobalt-bearing skarn-type iron ore formation. In this formation, postmagmatic sulfide mineralization containing copper and cobalt minerals is superimposed on magmatic titanomagnetite ores [31, 32]. Cobalt is present in titanomagnetite ores as part of cobalt-bearing pyrite [28] and, to a lesser extent, as cobaltite. For three deposits of this formation with identified cobalt mineralization, off-balance cobalt reserves and resources have been estimated, with average Co grades at individual sites reaching up to 0.04%.

The arsenide–cobalt formation represents a group of deposits and occurrences with diverse parageneses of arsenides, sulfoarsenides, and sulfides, all characterized by the predominant role of cobalt and cobalt-bearing minerals [9, 10]. A distinct arsenide–cobalt facies can be identified, as well as cobalt–nickel, bismuth–cobalt, gold–silver, and tin–tungsten facies of hydrothermal cobalt-bearing formations. The occurrences of the arsenide–cobalt formation are most extensively developed in the Altai–Sayan fold system, particularly concentrated in the Altai–Western Sayan province, as well as in the Seymchan and Yano–Adychan provinces (see Fig. 5, d), with one known occurrence in the Karelian province. Some bismuth–cobalt facies sites lie outside the delineated cobalt ore provinces – for example, the Uronaysky deposit in Zabaykalsky Krai {No. 71}, with cobalt reserves of 1.2 kt at 0.06% Co [33], and the Belogorskoe occurrence in Primorsky Krai {No. 72}, where overprinting mineralization is hosted by the skarn polymetallic ores of the Partizanskoye deposit [34]. The cobalt ore bodies of the arsenide–cobalt formation are predominantly vein-shaped and are spatially associated with fault zones. They also show a spatial association with alkaline-basaltic and granitoid magmatism, as well as proximity to pre-ore ophiolitic formations, which may have served as a source of cobalt mobilization during hydrothermal activity. The mineral form of cobalt in the arsenide–cobalt facies is represented by cobaltite, smaltite, and cobalt-bearing pyrite; in the cobalt–nickel facies – by cobaltite, smaltite, glaucodot, and tennantite; in the bismuth–cobalt facies – by cobaltite, glaucodot, and fahlore ores; in the gold–silver facies – by cobaltite and glaucodot; and in the tin–tungsten facies – by cobaltite and tetrahedrite-group minerals.

Cobalt production from the arsenide–cobalt formation was previously conducted at the Khovu-Aksy cobalt–nickel deposit (1956–1991) and at a group of cobalt-bearing gold deposits in the Seymchan area (Verkhne-Seymchanskoye, Vetrovoe).

In the Russian Federation, 43 deposits and occurrences of the arsenide–cobalt formation have been identified that contain recorded cobalt reserves or resources. Among them, 14 sites hold over 1 kt of cobalt, and 3 sites exceed 10 kt. The average cobalt grade in individual deposits reaches up to 2.26 %. This formation accounts for 3.0% of Russia’s total cobalt reserves (47.8 kt Co)9 (see Fig. 3).

Cobalt-bearing organophosphate uranium ore formation. Russia’s cobalt reserve balance includes 35.4 kt (2.3%) associated with complex phosphate–rare-earth–uranium ores in the Ergyninsky province, located in the Republic of Kalmykia [35]. These ores represent accumulations of fish bone remains embedded within marine clays of the Oligocene Maikop Horizon. The genesis of these metalliferous formations is interpreted as sedimentary, involving the sorption of uranium onto organic matter and the capture of other metals by diagenetic sulfides. In addition to uranium and cobalt, the Ergyninsky deposits contain reserves of other associated elements, including molybdenum, phosphorus, and rare-earth elements. Similar geological conditions are observed in the Baltic province (within the Baltic oil shale basin), where Ordovician Dictyonema shales (black oil shales) and obolites (phosphatic sandstones) host diagenetic uranium mineralization. These deposits contain documented reserves of associated vanadium, nickel, molybdenum, and rhenium [36]. Cobalt has also been identified, with a Co : Ni ratio of approximately 1 : 3, although its resources have not been assessed [36, 37]. Elevated concentrations of metals (U, Mo, Re, V, Ni, Co, Zn, Se) are also recorded in the oil shales of the Volga shale basin, including the Orlovskoye, Kashpir–Khvalynskoye, Perelyubskoye, and Kotsebin deposits [38]. The formation of these metalliferous bodies is attributed to the fossilization of organic matter during sedimentation, accompanied by the formation of diagenetic pyrite and the sorption of metals from seawater [39].

The direct development of cobalt-bearing organo-phosphate uranium ores is feasible primarily from the standpoint of uranium extraction. However, the proposed heap and in-situ leaching technologies offer the potential for the extraction of associated valuable components, including molybdenum, rhenium, nickel, cobalt, and others [40]. In a broader sense, considering the cobalt-bearing potential of uranium ore formations also brings attention to the metalliferous nature (including cobalt content) of the more widespread black shale formation [41].

Manganese minerals (asbolane, psilomelane, pyrolusite, etc.) serve as natural adsorbents of cobalt from infiltration solutions in both supergene and hypogene processes. In typical marine sedimentary–diagenetic and diagenetic manganese deposits, cobalt is consistently present (ranging from thousandths of a percent to 0.01%) [9]. This highlights the need to define a separate cobalt-bearing manganese ore formation, comprising ore objects formed in sedimentary basins proximal to substantial cobalt source areas – such as denudation zones of serpentinized ultrabasic massifs and their associated weathering crusts.

According to the inventory data of manganese deposits in the Russian Federation, 14 documented sites contain elevated concentrations of cobalt in manganese ores (up to 1%). The Mazulskoe deposit in Krasnoyarsk Krai, now depleted, was initially explored in the 1930s specifically as a cobalt–manganese deposit. Some occurrences of cobalt-bearing manganese ores are located within known cobalt ore provinces (Ural [42], Salair [43], Shoria–Khakass [4], and Easten Sayan[45]), consistent with their genesis through sorption of infiltrated cobalt released from serpentinites of ophiolitic complexes in these regions. However, occurrences of cobalt-bearing manganese ores are also found outside the established cobalt ore provinces—for example, the Mazulskoe deposit {No. 84} in Krasnoyarsk Krai (average grade of 0.023% Co) [46], and the Yuzhno-Khinganskoe and Bidzhanskoe deposits {No. 86} in the Jewish Autonomous Region (0.05% Co) [47]. These geological features suggest the possible existence of large-scale sources of mobile cobalt in the supergene environment and the potential for discovering new cobalt ore provinces.

The cobalt content of manganese ore formations has not been systematically studied, and cobalt resources in manganese deposits across Russia have not been assessed, despite the known tendency of manganese minerals to sorb infiltrating cobalt. Sampling of manganese ores for cobalt during geological exploration was sporadic and limited to isolated spot samples. Due to the generally low concentrations detected, cobalt did not attract significant interest. Consequently, there is no data on the distribution of cobalt within the ore bodies of manganese deposits or on potential enrichment zones.

The technogenic formation results from human impact on the subsurface, giving rise to new deposits of secondary mineral raw materials, including waste dumps of overburden and substandard ore, tailings and intermediate product storage from beneficiation processes, slag and calcine dumps from metallurgical processing, and mineralized mine waters [48]. In Russia’s cobalt reserves, the technogenic formation accounts for 0.8% of the balance (12.2 kt Co)10. Three technogenic deposits with registered cobalt reserves are known within the Russian Federation: the tailings storage facility of the Norilsk concentrator {No. 89} (reserves of 11.1 kt, 0.09% Co), the cooling pond Lake Barernoye of the nickel plant (0.023% Co) in Norilsk, and the waste dumps of substandard ores from the Allarechensky deposit {No. 88} in Murmansk Oblast (0.015% Co) [49]. For waste products derived from copper–nickel ores, a higher Co : Ni ratio is observed compared to the original ores, indicating relative cobalt enrichment.

Cobalt resources totaling 1.8 kt with an average grade of 0.112% have been estimated in only three of the five sluiced tailings cells formed from the beneficiation of arsenic–cobalt–nickel ores at the Tuvacobalt plant. As part of an environmental initiative aimed at neutralizing arsenic in long-term storage waste, the extraction of cobalt and nickel from these tailings is considered feasible [50].

At the beneficiation plant of the Gai Mining and Processing Plant (Gai GOK), which processes pyrite-bearing copper–zinc ores, pyrite concentrates from tailings containing up to 0.05% cobalt are stored separately. Similar storage facilities exist at other concentrators that process Ural copper–pyrite ores, as well as at former sulfuric acid production plants that accumulated pyrite cinders in dumps [51]. The cobalt resources of these technogenic stockpiles have not been evaluated.

Overall, the resource potential of technogenic deposits remains underestimated due to the limited scope of specialized geological exploration conducted at waste facilities of mining enterprises developing copper–nickel and copper–pyrite deposits.

Cobalt-rich ferromanganese crust formation. By decision of the International Seabed Authority (ISA), the Russian Federation has been granted rights to the Russian Exploration Area for cobalt-rich ferromanganese crusts (REA-CRC), located in the western segment of the Magellan Seamounts in the Pacific Ocean. Within this area, the State Scientific Center Yuzhmorgeologiya is conducting assessments of cobalt, nickel, and manganese resources in accordance with the ISA’s Regulations on Prospecting and Exploration for Cobalt-Rich Ferromanganese Crusts in the Area [52]. Cobalt-rich ferromanganese crusts are accumulations of iron and manganese hydroxides formed on exposed rock surfaces of underwater uplifts (guyots) at depths ranging from 800 to 3,000 meters. The crusts can reach thicknesses of up to 25 cm, with productivity rates of 60–80 kg/m2. The cobalt content in these crusts ranges from 0.5 to 0.7%, with estimated average grades of 0.50–0.61% across the evaluated blocks; nickel content is 0.4–0.5%, and manganese content is 19–23% [53]. The genesis of these crusts is interpreted as both hydrogenetic and biogeochemical, involving sorption of cobalt, nickel, and manganese from seawater by bacterial mats [54]. The estimated cobalt resources in the crusts on the Alba, Kotzebue, Govorov, and Vulkanolog guyots within the Russian Exploration Area amount to 110,000 t of cobalt [53, 55]. Overall, deposits of the cobalt-rich ferromanganese crust formation are considered highly promising targets for cobalt extraction, although progress in developing the required deep-sea mining technologies remains slow [56]. Closely related to this formation is the ferromanganese nodule formation of oceanic abyssal plains. However, due to their greater depths and the classification of cobalt as a secondary (by-product) component (Co content of 0.22–0.29%), they are of lesser interest compared to CRC deposits [53], despite the estimated cobalt resources in the Clarion–Clipperton Zone (CCZ) ferromanganese nodules within the Russian contract area reaching 985,000 t.

The confirmed presence of significant cobalt-rich ferromanganese crust deposits in the World Ocean indicates the possibility of analogous formations within onshore geological structures in the Russian Federation. To explore this potential, it is essential to identify geological complexes with conditions resembling those of present-day marine environments where cobalt precipitates from seawater. This includes developing exploration criteria, such as revising existing geological data, conducting prospecting activities, and evaluating CRC-type resources. The importance of this task is underscored by the presence of continental analogues—for example, the occurrences in the Pavlovskaya area (site No. 87) in Primorsky Krai [57].

Cobalt ore provinces

Due to the predominance of deposits belonging to the copper–nickel formation and, to some extent, the copper–pyrite formation, cobalt ore provinces partially or entirely overlap with the contours of copper ore provinces – namely, the North Caucasus, Voronezh, Karelian, Kola, Ural, Easten Sayan, Norilsk, North Baikal, Dzhugdzhur, Koryak, and Kamchatka provinces [16]. Provinces have been identified that are dominated by deposits of the silicate–cobalt–nickel formation (Salair province), skarn-type iron ore formation (Shoria–Khakass province), arsenide–cobalt formation (Altai–Western Sayan, Yana–Adycha, and Seymchan provinces), and uranium–phosphate formation (Ergyninsky and Baltic provinces).

Numerous deposits of the copper–pyrite formation are known in the North Caucasus province. Some of them have registered associated cobalt reserves – for example, the Kizil-Dere reserve deposit {No. 42} with 17.7 kt Co at an average grade of 0.03% Co [24], and the Khudes deposit {No. 41}, which is being prepared for mining (combined reserves and resources amount to 21.2 kt Co, 0.02% Co). In total, the North Caucasus province accounts for 24.2 kt of economically viable (balance) cobalt reserves, representing 1.5% of the national total (see Fig. 8), or 31.6% of the reserves attributed to the copper–pyrite formation (see Fig. 5, b). Numerous copper–pyrite occurrences have also been identified in the region, some of which contain cobalt mineralization (cobalt-bearing pyrite, cobaltite) [58, 59].

Fig. 8. Volumes of recorded cobalt reserves in the Russian Federation by province as of 2021

Sources: State report on the status and use of the mineral resources o f the Russian Federation in 2021. Ministry of Natural Resources and Environment of the Russian Federation; 2022. 626 p. URL: https://www.mnr.gov.ru/docs/gosudarstvennye_doklady/o_sostoyanii_i_ispolzovanii_mineralno_syrevykh_resursov_rossiyskoy_federatsii/; Information on the status and prospects for the use of the mi neral resource base of the regions of the Russian Federation (as of January 1, 2022 ). St. Petersburg: VSEGEI, State Assignment No. 049-00018-22-01 dated January 14, 2022. 2022. URL: http://atlaspacket.vsegei.ru/?v=msb2021#91474d2e700eb6c90

In the Ergyninsky (Kalmykia) province, there are deposits and occurrences of the cobalt-bearing organophosphate uranium ore formation [35, 40], including the Bogorodskoe deposit {No. 78} (combined reserves and resources: 20.8 kt Co, 0.04% Co) and the Shargadyk deposit {No. 79} (12.6 kt Co, 0.01% Co). These ore bodies consist of accumulations of uranium-bearing fossilized fish bones and scales cemented by clay material containing pyrite and melnikovite. Cobalt is concentrated in diagenetic pyrite and melnikovite. Open-pit mining has been proposed for the uranium deposits of the Ergyninsky district, followed by heap leaching of valuable components using sulfuric acid and nitric acid schemes [40]. The cobalt balance reserves of the Ergyninsky province (4 kt) account for 0.26% of Russia’s total cobalt reserves.

In the Voronezh province, deposits and occurrences of the cobalt-bearing copper–nickel ore formation are known [60, 61], including the Elan deposit {№ 1} with recorded associated cobalt reserves of 15.3 kt at an average grade of 0.036% Co, and the Elkinskoye deposit (5 kt Co, 0.03% Co). Cobalt is concentrated in pentlandite, cobaltite, and gersdorffite. The cobalt reserves of the Voronezh province (20.7 kt) represent 2.12% of Russia’s copper–nickel ore formation reserves.

In the Baltic province, there are deposits and occurrences of the cobalt-bearing organophosphate uranium ore formation [35, 36], which were mined in the 1950s for uranium extraction [62]. Known uranium deposits in the area with recorded associated reserves of nickel, vanadium, molybdenum, and rhenium include Kummolovskoe, Kotlovskoe, Kaibolovskoe, Krasnoselskoe, and Ranolovskoe. Although cobalt resources in these uranium-bearing sediments have not been assessed, estimates based on nickel-to-cobalt ratios suggest a cumulative cobalt potential of up to 4 kt with an average grade of 0.013% Co across the known deposits [36, 37]. Cobalt recovery (together with other associated valuable components) may be feasible using proposed heap and in-situ leaching technologies applied to the uranium-bearing Dictyonema shales of the Baltic region [40]. No cobalt balance reserves have been recorded for the Baltic province.

The Karelian province is located in the southeastern part of the Fennoscandian Shield. Based on geological exploration, 16 deposits and occurrences with associated cobalt have been identified in this area, including 13 belonging to the copper–nickel formation, 2 to the low-sulfide platinum-group element (PGE) formation, and one to the gold–silver facies of the arsenide–cobalt formation. The most promising are the copper–nickel deposits of Semchozerskoe {No. 3} (resources: 80 kt Co, average grade 0.02 % Co), Pedrorechenskoye {No. 2} (50 kt Co, 0.06% Co) [63], and Voloshovskoe {No. 4} (14 kt Co, 0.02% Co), all characterized by copper–nickel ores with associated cobalt mineralization [64]. The low-sulfide PGE formation includes the Viksha occurrence (Vikshozero, Kenti, and Shargi areas) {No. 21} (4.5 kt Co, 0.01% Co) [65] and the Shalozerskoye (Kukruchey) site {No. 20} (0.15 kt Co, 0.17% Co) [63]. An occurrence of the gold–silver facies of the arsenide–cobalt formation with cobaltite and glaucodot has also been identified – Orekhozero {No. 75} (2.5 kt Co, 0.07% Co) [66]. The Karelian province accounts for 10 kt of cobalt balance reserves, or 0.64% of the national total.

The Kola province is located in the northern part of the Fennoscandian Shield, where the rift-related Pechenga–Imandra–Varzuga greenstone belt hosts numerous Paleoproterozoic layered intrusions. These intrusions include deposits and occurrences of sulfide copper–nickel and low-sulfide PGE formations with associated cobalt–copper–nickel mineralization [67, 68], as well as occurrences of cobalt-bearing vanadium-rich titanomagnetite ores of magmatic origin [31]. The Kola province holds 116.1 kt of cobalt balance reserves, which accounts for 7.4% of Russia’s total (see Fig. 8).

Within the Kola province, 30 deposits and occurrences of the copper–nickel formation have been identified, with recorded reserves and resources of associated cobalt. These include the actively developed Zhdanovskoe deposit {No. 3} (combined reserves and resources: 68 kt Co, average grade 0.024% Co), Sopchuivench {No. 5} (23.7 kt Co, 0.01% Co), Nyud-Moroshkovoe {No. 7} (21.3 kt Co, 0.02% Co), Poaz {No. 6} (21.2 kt Co, 0.01% Co), Nittis–Kumuzhya–Travyanaya {No. 8} (16.9 kt Co, 0.19% Co), and Tundrovoe {№ 4} (16.7 kt Co, 0.023% Co). In addition, there are 9 other cobalt–copper–nickel sites with total cobalt reserves and resources exceeding 1 kt. In total, the copper–nickel deposits of the Kola province account for 116 kt of balance cobalt reserves, or 11.9% of the cobalt reserves hosted in copper–nickel ores in Russia (see Fig. 5, a). Associated cobalt mineralization is also known at the platinum-group element (PGE) deposit of Kievey {No. 22} and the PGE occurrences of Monchetundrovskoe {No. 23}, Chuarvy Vostochnoye, and Severny Kamenik. Cobalt resources at these PGE sites are generally small, typically under 1 kt.

In the East Kievey Belt of the Baltic titanomagnetite province, geological exploration has confirmed the presence of cobalt at the vanadium-bearing titanomagnetite magmatic formation of the Magazin–Musyur deposit {No. 60} (resources: 51.5 kt Co, 0.02% Co), located within the Early Proterozoic Magazin–Musyur gabbro-anorthosite intrusion.

The Ural province is located within the Ural Fold System. This region hosts deposits and occurrences of silicate cobalt–nickel ores, as well as copper–pyrite, skarn-type iron ore, and PGE–copper–nickel formations, all featuring associated cobalt mineralization [26, 67, 70, 71]. The Ural province accounts for 385.7 kt of Russia’s balance cobalt reserves (24.7%), yet mining of silicate cobalt–nickel ores has been discontinued since 2013, and cobalt is not recovered during the development of cobalt-bearing copper–pyrite and iron ore deposits.

Supergene deposits of the oxide–silicate cobalt–nickel formation in the Ural province are represented by residual and infiltration products of Mesozoic exogenous weathering of serpentinized ultramafic and mafic rocks in the Orsk–Khalil (Southern Urals), Ufaley, and Rezh (Middle Urals) cobalt–nickel ore districts [21, 23]. Based on formation characteristics, the primary substrate for the development of these supergene deposits consists of cobalt- and nickel-bearing ultrabasic rocks. Of their total outcrop area within the Ural province, 89.7% is occupied by rocks of the dunite–harzburgite formation, 8.7% by the dunite–clinopyroxenite formation, and 1.6% by the pyroxenite–peridotite and alkaline olivine basalt formations [13].

The Ural province hosts 45 deposits and occurrences of silicate cobalt–nickel ores, including the Buruktal deposit {No. 33} (reserves: 136.7 kt Co at an average grade of 0.058% Co) [72], Serovskoe {No. 37} (133.8 kt Co, 0.026% Co), Sakharinskoe {No. 35} (reserves + resources: 11.7 kt Co, 0.06%), Novokievskoe {No. 34} (reserves: 15.5 kt Co, 0.08% Co), Elizavetinskoe {No. 36} (14.1 kt Co, 0.07% Co), as well as 20 cobalt–copper–nickel sites with total cobalt reserves and resources in the range of 1–10 kt. Cobalt is concentrated in asbolane, psilomelane, cobalt–nickel oxyhydroxides, nontronite, and hydrogoethite. Among the promising sites is the Yareney area {No. 38} in the Polar Urals (resources: 125 kt Co, 0.11% Co), spatially associated with a manganese-rich siallite–ferruginous weathering crust developed on Devonian sandstone–shale formations. The ore mineralization here is represented by fine-crystalline, granular, or botryoidal aggregates of cobalt–nickel asbolane.

The accounted cobalt reserves in silicate cobalt–nickel deposits of the Ural province amount to 308.6 kt, representing 99.1% of Russia’s total reserves in this formation (see Fig. 5, b). Until 2013, silicate cobalt–nickel ores were extracted from deposits in the Ural province by Southern Urals Nickel Plant PJSC and processed primarily into ferronickel at the Orsk, Ufalei, and Rezh nickel plants. Many small and medium-sized cobalt–nickel deposits have been either fully or partially depleted. Since cobalt is considered a harmful impurity in ferronickel production, mining operations prioritized selective extraction of highgrade nickel ores, leaving behind pillars of boulder asbolane ores that were low in nickel but rich in cobalt.

In the copper–pyrite formation of the Ural province, cobalt is found in so-called Cyprus-type and Urals-type sulfur-rich copper–pyrite deposits. These are associated with submarine sedimentary–volcanogenic basaltic formations formed during the early stages of the eugeosynclinal development of the Southern and Central Urals [69]. A total of 21 cobalt-bearing copper–pyrite deposits and occurrences have been identified in the province, with cobalt reserves or resources reported at each. Among them, nine contain over 1 kt of cobalt, and one – Gai deposit {No. 43} –contains more than 10 kt (resources: 17 kt Co at an average grade of 0.02% Co) [73].

The balance reserves of cobalt in the Ural province amount to 50.8 kt of Co, or 66.3% of Russia’s cobalt reserves hosted in copper–pyrite formations (see Fig. 5, c). Cobalt-bearing Cyprus-type sulfur–copper–pyrite deposits are generally small in terms of reserves and largely depleted, such as the Dergamysh {No. 44} [74], Ivanovskoye [25], and Ishkinino [75] deposits in the Southern Urals, and the Pyshminsko-Klyuchevskoye {No. 45} deposit [76] in the Middle Urals. In Cyprus-type deposits, cobalt occurs predominantly in the form of cobaltite, which sometimes forms monomineralic concentrations in massive sulfide bodies. Average cobalt contents in these deposits range from 0.05% (Dergamysh) to 0.12% (Southern Yuluk). Cobalt was recovered from pyrite ores during the development of some Cyprus-type deposits (Dergamysh – 1.3 kt; Nikitovskoye – 0.1 kt). Ural-type cobalt-bearing copper–zinc–pyrite deposits are characterized by significant reserves of zinc and copper, with associated cobalt recorded at a number of sites, including: Saumskoe {№ 46} (reserves: 37 kt Co, 0.058% Co), Gaysky (reserves + resources: 17 kt Co, 0.02% Co), Ivanovskoe, Osenneye (reserves: 4.4 kt Co, 0.062% Co), Shemurskoe (reserves: 4.3 kt Co, 0.06% Co), Novo-Shemurskoye (reserves: 4.3 kt Co, 0.07% Co), Sibayskoye (reserves: 2.4 kt Co, 0.026% Co), among others. In these deposits, cobalt is primarily concentrated in cobalt-bearing pyrite, and less commonly in cobalt-bearing pyrrhotite. However, copper–zinc ores are generally low in cobalt compared to true cobalt-bearing pyrite ores. As a result, cobalt does not accumulate in the final metals or industrial products during ore processing. Consequently, cobalt-bearing pyrite ores either remain unmined (as they are of no interest for copper and zinc extraction) or end up in processing tailings.

The cobalt-bearing skarn-type iron ore formation in the Ural province is represented by Silurian–Devonian contact-metasomatic bodies overprinted by later copper and cobalt sulfide mineralization [12]. In total, 8 deposits and occurrences of the cobalt-bearing skarn-type iron ore formation have been identified in the Ural province, all of which have assessed cobalt reserves or resources, with 6 sites exceeding 1 kt Co. Five of these deposits are located in the Middle Urals: Techenskoe {No. 50} (resources: 13.6 kt Co, at an average grade of 0.028% Co), Severo-Goroblagodatkoye (reserves: 8.7 kt Co, 0.01% Co), Peschanskoe {No. 51} (reserves: 6.9 kt Co, 0.02% Co), Lebyazhinskoye (reserves: 6 kt Co, 0.02% Co), and Vysokogorsk (reserves 3.4 kt Co, 0.03% Co) [12]; and one deposit is in the Polar Urals: Novogodnee (resources: 2.7 kt Co, 0.015%) [77]. Cobalt is primarily concentrated in cobalt-bearing pyrite, as well as in cobaltite (at the Peschanskoe, Lebyazhinskoye, and Vysokogorsk deposits) and pyrrhotite (at Novogodnee). The Ural province accounts for 28.1 kt of cobalt in reserves, representing 19.9% of Russia’s total reserves in the cobalt-bearing skarn-type iron ore formation (see Fig. 5, d).

The Ural province also hosts an operating deposit of vanadium-bearing titanomagnetite formation with associated cobalt mineralization – the Volkovsky copper–titanomagnetite deposit {№ 61} (resources: 5 kt Co, 0.004% Co) [32]. It is composed of Silurian–Devonian contact-metasomatic bodies with later overprinting of copper and cobalt sulfide mineralization. Cobalt is not recovered from the copper concentrates at the Volkovsky deposit due to economic considerations.

The supergene deposits of the oxide–silicate cobalt–nickel formation in the Salair province are represented by linear and areal weathering crusts of Mesozoic exogenous origin, developed over serpentinized Cambrian ultramafic intrusions of the Salair ophiolite belt [9]. Fifteen deposits and occurrences have been identified here, including 7 with total cobalt reserves and resources exceeding 1 kt: Belininskoe {No. 39} (reserves: 2.8 kt Co, 0.04% Co), Alexandrovskoye {No. 40} (reserves: 1.1 kt Co, 0.11% Co), Uksunayskoye (resources: 6 kt Co, 0.04% Co), Stary Tyagun (resources: 6 kt Co, 0.05% Co), Tyagunskoe (resources: 5 kt Co, 0.06% Co), Kolpachek (resources: 4 kt Co, 0.01% Co), and Yaminskoye (resources: 1 kt Co, 0.07% Co). At most of these sites, cobalt occurs in nickel-bearing nontronite, although noteworthy concentrations are found in goethite and psilomelane (e.g., the Alexandrovskoye deposit), as well as in cobalt-bearing asbolane at the Novofirsovskoye (up to 1.31% Co) and Kaincha (up to 10% Co) occurrences. Previously, these supergene silicate cobalt–nickel deposits in the Salair province were not considered promising due to their small size, but with advances in underground leaching technologies for nickel and cobalt, sulfuric acid leaching of cobalt–nickel ores were investigated at the Belininskoe deposit [78].

Among other cobalt-bearing sites in the Salair province are the Sedova Zaimka occurrence of the copper–nickel formation (0.016% Co, 0.3% Cu, and 0.48% Ni), featuring superimposed cobaltite–gersdorffite mineralization [79], and the Matyuzhikha occurrence of the manganese ore formation (up to 1% Co) in a residual Silurian weathering crust [43].

The Shoria–Khakass province is situated in the southern part of the Kuznetsk Alatau orogenic structure, within the Mrassko–Batenevo anticlinal structural–formational zone. This zone is characterized by a thick sequence of Riphean–Cambrian–Ordovician deposits rich in volcanic rocks of the basalt–andesite–trachyte–liparite group and was shaped by Late Early Paleozoic dioritic and plagiogranitic magmatism of the Salair or Early Caledonian tectonic cycle [80]. The region hosts deposits and occurrences of the skarn-type iron ore formation, as well as of the arsenic–cobalt and manganese ore formations. The total cobalt reserves in the Shoria–Khakass province amount to 115.9 kt, representing 7.4% of Russia’s total cobalt reserves (see Fig. 8).

The deposits of the skarn-type iron ore formation are Cambrian contact-metasomatic formations with superimposed cobalt mineralization. Within the Shoria–Khakass province, 7 deposits and occurrences of cobalt-bearing skarn-type iron ores are known, of which 5 contain over 1 kt of cobalt, and 4 exceed 10 kt. These include the Tashtagol deposit {No. 53} (reserves: 65.4 kt Co, 0.02% Co), Volkovsky {No. 56} (resources: 42 kt Co, 0.02% Co), Anzasskoe {No. 54} (reserves: 29.9 kt Co, 0.02% Co), and Abakanskoe {No. 55} (reserves: 26.9 kt Co, 0.18% Co). Cobalt is primarily hosted in cobalt-bearing pyrite, and in some cases as the cobaltite mineral phase, the latter forming locally enriched zones within the iron ore at the Abakanskoe deposit. Cobalt-bearing fahlore ores are also present at the Tashtagol deposit, while cobalt-bearing magnetite occurs at Volkovsky. As the Shoria–Khakass deposits are developed primarily for high-grade iron ore without beneficiation, cobalt is not recovered. Cobalt reserves in the skarn-type iron ore deposits of the Shoria–Khakass province amount to 111 kt, or 77.6% of Russia’s total reserves in this formation (see Fig. 5, d).

In the Shoria-Khakass province, geological exploration has identified occurrences of the hydrothermal arsenic–cobalt formation, including the Bazasskoe occurrence {No. 63} (resources of 7 kt Co at an average grade of 0.25% Co, with tennantite and annabergite mineralization), the Butrakhtinskoe deposit {No. 64} (1.2 kt Co, 0.16% Co, with tennantite and cobaltite mineralization), and the Kharadzhulskoye deposit {No. 74} (3.7 kt Co, 0.08% Co, with cobaltite and cobalt-bearing pyrite mineralization). Cobalt reserves of the arsenic–cobalt formation in the Shoria-Khakass province amount to 4.9 kt, or 10.2% of Russia’s total cobalt reserves of this formation (see Fig. 5, d).

At the Selezenskoe deposit {№ 78}, a manganese-ore formation located near the Tashtagol iron ore deposit, cobalt has been recorded at concentrations of up to 0.016% [81].

The Altai–Western Sayan province is the region with the highest concentration of hydrothermal cobalt mineralization in Russia. Targeted exploration for deposits of the arsenic–cobalt formation has been carried out in this area [82]. Nearly all facies of the arsenic–cobalt formation are found in this region:

– true arsenic–cobalt occurrences: Yustydskoye [83], Olen-Dzhularskoye [82], Zagadka (Karagemskoye) [84], Toshtuozekskoye (0.15% Co), Svetly (1.45% Co) [82], Ulandryk [85], Tsentralny Akchat (0.15% Co), Shemush-Dag (0.19% Co), Bai-Taiga, Sagsayskoye, Kok-Uzek [82], Talailyk, Shemushdag, Aksumon, Akoyuk, Oyukhemskoye [10];

– nickel–cobalt occurrences: Khovu-Aksy deposit {No. 67} (19.8 kt Co, 2.26% Co) [86]; occurrences Atbashi {No. 65} (9.4 kt Co, 0.22% Co), Kuruozek {No. 66} (7.3 kt Co, 0.18% Co) [82], Vladimirovskoye (0.5% Co) [87], Kokkaya (0.7% Co), Askhatin-Gol, Khuren-Taiga, Kyzyl-Oyuk [82], Akol, Uzunkhem, Uzyuk, Sarytash [10];

– bismuth–cobalt occurrences: Karakul deposit {No. 69} (25.7 kt Co, 0.33% Co) [88]; occurrences Yantau {№ 68} (1.6 kt Co, 0.03% Co), Perevalnoe {No. 70} (6.1 kt Co, 0.08% Co), Uzunoyskoye, Mogenburenskoye, Kaat-Taiga [82], Chergak [89], Butrakhtinskoe, Dzhulukul [82], Kyzylshin [10].

Arsenic–cobalt deposits occur as zones or veins with sulfide–arsenide and sulfoarsenide mineralization, including cobaltite, glaucodot, Co–Ni–arsenopyrite, cobalt-bearing pyrite and pyrrhotite, as well as other cobalt sulfides, arsenides, and sulfoarsenides [86, 88]. The cobalt ores also contain minerals of nickel, copper, gold, bismuth, tungsten, and uranium.

Cobalt mineralization in this province occurred in three distinct metallogenic epochs, corresponding to periods of extensive ultramafic and mafic magmatism [90, 91]:

– Devonian–Early Carboniferous (D–C₁): Yustydskoye, Sagsayskoye, Khovu-Aksy, Vladimirovskoye, Butrakhtinskoe;

– Permian–Triassic (P₂–T): Chergakskoye, Askhatin-Gol, Khuren-Taiga, Uzunoyskoye, Mogenburenskoye;

– Late Jurassic–Early Cretaceous (J₃–K₁): Kok-Uzek, Kyzyl-Oyuk, Khuren-Taiga, Kaat-Taiga, Sergeyevskoye, Dzhulukul.

It is evident that the mineral facies of cobalt deposits form parageneses based on the surrounding rock substrate (as the source of ore material and metasomatic energy) and are not bound to a specific age, being observed across all three epochs.

A total of 27 deposits and occurrences of the arsenic–cobalt formation is known in the Altai–Western Sayan province, of which 7 contain cobalt reserves or resources exceeding 1 kt, and 3 exceed 10 kt. Individual deposits feature average cobalt grades of up to 2.26%. The province accounts for 82% of Russia’s balance cobalt reserves of the arsenic–cobalt formation (39.2 kt Co)11; see Fig. 5, d), or 2.5% of the country’s total cobalt reserves. The Altai–Western Sayan province remains the most promising area for the discovery of new arsenic–cobalt formation deposits.

The Eastern Sayan province is located at the junction of the northeastern part of the Altai–Sayan orogenic zone and the southwestern margin of the Siberian Platform. The region hosts deposits and occurrences of copper–nickel (3 sites), pyrite (1 site), skarn-type iron ore (1 site), and manganese (3 sites) formations. The Eastern Sayan province accounts for 96 kt of cobalt reserves, representing 6.1% of Russia’s cobalt reserve base (see Fig. 8).

The copper–nickel formation deposits are associated with serpentinized ultrabasic rocks of the gabbro–peridotite–dunite magmatic formation and contain disseminated cobalt–PGE–copper–nickel mineralization. The Kingash {No. 17} (reserves: 46.0 kt Co, 0.02% Co) [92] and Verkhnekingash {№ 18} (reserves: 44.1 kt Co, 0.0017% Co) [93] deposits are being prepared for mining operations targeting Ni, Cu, Pt, Pd, and Co. Geological exploration is underway at the Tokty-Oy site {No. 19}, which hosts cobalt–copper–nickel mineralization (resources: 30 kt Co, 0.02% Co). The Eastern Sayan province holds 9.1% of Russia’s cobalt reserves associated with the copper–nickel formation (90.5kt) (see Fig. 5, a).

A notable geological site assigned to the pyrite formation is the Savin cobalt deposit {No. 48} (reserves: 1.9 kt Co, 0.0017% Co), where cobalt-bearing pyrite mineralization is superimposed on the main magnesite body of the Savin deposit [94].

In the Irbinskaya group of Cambrian skarn-type iron ore deposits, cobalt-bearing pyrite mineralization has been identified at the Izygskoye deposit {No. 57} (reserves: 3.9 kt Co, 0.011% Co).

In the Prisayan Depression, elevated cobalt concentrations have been recorded in manganese-bearing horizons of the Upper Riphean Tagul Formation (Izansko–Bolsheerminskaya manganese-bearing zone). These include the Kamenskoe manganese deposit {No. 85} (0.01% Co) and the Rudnoye (0.014% Co) and Zapadny site (0.01% Co) occurrences [95]. Cobalt mineralization has also been reported at the Nikolaevskoye deposit within the same manganese-bearing zone (0.02–0.15% Co) [45].

The Norilsk province is located in the northwestern part of the Siberian Platform at its junction with the Yenisei–Khatanga Trough. The region hosts world-class copper–nickel formation deposits notable for both the scale and quality of their reserves. Cobalt is recovered as a by-product of ore processing. The currently operating deposits include Oktyabrskoe-Cu-Ni {No. 11} (reserves :376.6 kt Co, 0.034% Co), Talnakhskoe {No. 12} (reserves: 230.5 kt Co, 0.026% Co), and Norilsk-1 {No. 13} (reserves: 80.3 kt Co, 0.016% Co). The Maslovskoe {No. 14} (reserves: 26.3 kt Co, 0.013% Co) and Chernogorskoe {No. 15} (reserves: 20.9 kt Co, 0.026% Co) deposits are being prepared for development [96]. Cobalt is also accounted for in the resources of other deposits in the province, including Vologochanskoe {No. 12} (resources: 31.8 kt Co, 0.019% Co), the Southern Norilsk branch (resources: 23.5 kt Co, 0.01% Co), Norilsk-2 (resources: 3.9 kt Co, 0.03% Co), Gorozubovskoye (resources: 6.2 kt Co, 0.15% Co), and an exploration area in the Chibichete River basin (resources: 2.6 kt Co, 0.01% Co). The Norilsk province accounts for 734.3 kt of cobalt reserves, representing 47% of Russia’s cobalt reserve base (see Fig. 8), and 723.2 kt of cobalt reserves in the copper–nickel formation, or 74% of Russia’s reserves in this formation (see Fig. 5, a).

The North Baikal province is located in the southeastern part of the fold belt bordering the Siberian Platform, where platinum–copper–nickel mineralization has been identified within dunite–troctolite–gabbro intrusions [97]. Since the 1980s, authorial assessments have been carried out to evaluate the significance of copper–nickel formation deposits and occurrences in this province, including the Chaikskoye deposit {No. 20} (resources: 27 kt Co, 0.02% Co) [98], the Yoko-Dovyren massif (resources: 9.5 kt Co, up to 0.14% Co), the Avkit massif (up to 0.032% Co), and the Marinka massif (up to 0.089% Co) [99].

The Dzhugdzhur Province is located on the eastern flank of the Dzhugdzhur–Stanovoy mobile belt, which experienced Proterozoic and Mesozoic tectonic reactivation. This region hosts deposits and occurrences of the copper–nickel formation with associated cobalt mineralization [99]. The most developed deposit is Kun-Man’ye {No. 21} (reserves: 25.1 kt Co, 0.015% Co) [100], and copper–nickel mineralization has also been identified in the Nyandoma prospective area in the eastern part of the province [101]. The Dzhugdzhur Province accounts for 2.6% of Russia’s balance reserves of cobalt in copper–nickel formations (25.1 kt). The province also contains 25.1 kt of cobalt balance reserves overall (1.5% of the national total) (see Fig. 8) or 2.5% of Russia’s cobalt reserves in copper–nickel formations (see Fig. 5, a).

The Yana–Adycha province is situated within the Kular–Nera belt of the Verkhoyansk–Kolyma fold system, which formed in the Jurassic–Cretaceous period as a result of the intrusion of collisional granitoids of the Kolyma Series into Triassic terrigenous sediments, producing gold–quartz, gold–antimony, and tin–tungsten mineral systems [102]. The tin–tungsten ore systems of the region are characterized by the presence of Early Cretaceous arsenopyrite–pyrite and stibnite mineralization [102].

The Alys-Khaya tin–tungsten deposit {No. 77} (reserves:1.4 kt Co, 0.08% Co) is classified as a tin–tungsten facies of the arsenic–cobalt formation [102]. Cobalt mineralization is represented by cobaltite and cobalt-bearing arsenopyrite and fahlore ores. Other occurrences of this facies include the Ilin-Tas deposit (reserves of 0.4 kt Co, 0.015% Co), and the Burgachan and Ergelyakhskoye occurrences.

Ophiolite complexes are absent in the Yana–Adycha province, and it is assumed that the source of siderophile elements (Co, Ni, Cr) in the ore bodies may be deep-seated, yet unidentified sources [8].

The Seymchan province is located within the Sugoy Trough of the Verkhoyansk–Kolyma fold system, composed of Paleozoic terrigenous–carbonate sediments intruded by Cretaceous alkaline granites, which are associated with gold ore deposits of the gold–rare-metal formation [103]. The granitoids are characterized by elevated concentrations of Ni, Cu, As, Pb, Sr, Ag, Nb, and Y, while the gold ore bodies exhibit high contents of volatile elements (As, Bi, Se, Te) [103, 104]. The Seymchan province hosts cobalt deposits of the arsenic–cobalt and pyrite formations.

The Verkhne-Seymchan deposit of the bismuth–cobalt facies of the arsenic–cobalt formation {No. 73} (reserves: 0.7 kt Co, 0.11% Co) was mined in the 1950s, yielding 0.8 kt of Co (including from the adjacent Vetrovoe deposit). Cobalt is present in the form of cobaltite, gersdorffite, and glaucodot. The Verkhne-Seymchan ore cluster also includes other deposits and occurrences of the bismuth–cobalt facies such as Vetvistoye, Volochok, Vetrovoe [104], Levo-Seymkanskoye, Obkhod [105], Solnechnoye, Vysoky, Khetagchan, and Khalali [103].

The Podgornoe occurrence {No. 76}, with combined reserves and resources of 1.2 kt Co at 2.6% Co, belongs to the gold–silver facies of the arsenic–cobalt formation. The cobalt mineralization occurs in the form of cobalt-bearing arsenopyrite. The Natalka gold deposit, which also contains cobalt-bearing arsenopyrite mineralization, can likewise be attributed to this facies [106].

The Porozhistoye tin occurrence, with cobalt-bearing arsenopyrite mineralization, belongs to the tin–tungsten facies of the arsenic–cobalt formation.

At the Degdenreken (Piritovy) copper deposit of the copper–pyrite formation {No. 49} (resources: 80 kt at 0.01% Co), cobaltite mineralization has been identified.

As in the Yano–Adychan province, ophiolite complexes – traditionally regarded as cobalt sources for cobalt ore formations – are absent in the Seymchan province.

The Koryak province is located in the northern part of the Koryak–Kamchatka Mesozoic–Cenozoic volcanic belt, where occurrences of low-sulfide PGE–copper–nickel formation have been identified within Alpine-type mafic–ultramafic complexes [18, 19]. The identified targets within the Mainitskaya {No. 30} and Valaginskaya–Karaginskaya {No. 31} [19] prospective areas, as well as the Ust-Beloe, Chirina, Krasnaya Gora, and Snezhnoye {No. 32} occurrences of the low-sulfide PGE formation, are associated with copper–nickel mineralization and contain cobalt as an accessory component [28]. The geology of the Koryak province remains poorly explored, and the discovery of new deposits of the PGE–copper–nickel formation, including those with cobalt content, is considered highly likely.

The Kamchatka province is situated in the southern part of the Koryak–Kamchatka Mesozoic–Cenozoic volcanic belt, where copper–nickel formation deposits associated with hornblende peridotites and gabbroids have been identified within the Late Cretaceous–Paleocene Kvinum–Kuvalarog metallogenic zone. These include the currently operating Shanuch deposit {No. 24} (reserves: 1.9 kt, 0.145% Co) [107], whose copper–nickel ores are exported. This metallogenic zone also hosts deposits of cobalt-bearing copper–nickel formation: the Dukukskoe {No. 23} (resources: 15 kt, 0.03% Co), Kvinum I (resources: 5 kt, 0.11% Co), Kvinum II (resources: 2 kt, 0.05% Co), and Kuvalarog (0.01% Co).

In total, the Kamchatka province accounts for 1.9 kt of cobalt reserves (0.1% of Russia’s total), or 0.2% of the country’s copper–nickel formation reserves (see Fig. 5, a).

4 State report on the status and use of the mineral resources of the Russian Federation in 2021. Ministry of Natural Resources and Environment of the Russian Federation; 2022. 626 p. URL: https://www.mnr.gov.ru/docs/gosudarstvennye_doklady/o_sostoyanii_i_ispolzovanii_mineralno_syrevykh_resursov_rossiyskoy_federatsii/

5 Ibid.

6 State report on the status and use of the mineral resources of the Russian Federation in 2021. Ministry of Natural Resources and Environment of the Russian Federation; 2022. 626 p URL: https://www.mnr.gov.ru/docs/gosudarstvennye_doklady/o_sostoyanii_i_ispolzovanii_mineralno_syrevykh_resursov_rossiyskoy_federatsii/; Information on the status and prospects for the use of the mineral resource base of the regions of the Russian Federation (as of January 1, 2022). St. Petersburg: VSEGEI, State Assignment No. 049-00018-22-01 dated January 14, 2022. 2022. URL: http://atlaspacket.vsegei.ru/?v=msb2021#91474d2e700eb6c90

7 State report on the status and use of the mineral resources of the Russian Federation in 2021. Ministry of Natural Resources and Environment of the Russian Federation; 2022. 626 p. URL: https://www.mnr.gov.ru/docs/gosudarstvennye_doklady/o_sostoyanii_i_ispolzovanii_mineralno_syrevykh_resursov_rossiyskoy_federatsii/

8 Ibid.

9 Ibid.

10 Ibid.

11 Ibid.

Discussion of challenges in Russia’s cobalt resource base

Difficulties in planning and managing cobalt production volumes. The majority of cobalt reserves in the Russian Federation are concentrated in ore formations where cobalt occurs as an associated component and is recovered as a by-product. At such deposits, production planning and management are focused on maximizing the recovery of the main ore components, while the extraction of by-products like cobalt is treated as a secondary objective. Consequently, for complex deposits with associated cobalt, it is virtually impossible to regulate production volumes based on market demand for cobalt products.

Several development projects for new copper–nickel formation deposits include provisions for by-product cobalt recovery, with the following projected annual outputs (kt/year): Chernogorskoe (0.73), Norilsk I, southern section (0.7), Maslovskoye (0.7), Kingashs and Verkhnekingash (4.0), Kun-Manie (1.8), and Elan and Elkinskoye (0.9)12. These projects will be launched at different times, and some of the additional copper–nickel ore volumes will be processed at PJSC MMC Norilsk Nickel’s existing metallurgical facilities without increasing total throughput. As a result, the actual increase in cobalt output will be significantly lower. The Buruktal silicate cobalt–nickel deposit is also expected to yield by-product cobalt, with projected output of up to 0.13 kt/year13. Overall, cobalt production from copper–nickel formation deposits remains tied to copper and nickel output levels. As such, production volumes can only be estimated based on expected metal recovery, not on market demand.