Scroll to:

Application of polystyrene sulfonates for the depression of magnesium-containing silicates in copper-nickel ore flotation

https://doi.org/10.17073/2500-0632-2025-06-419

Abstract

It is very urgent to increase the efficiency of depressing magnesium-containing silicates (MS) in the course of the flotation of copper-nickel ores to reduce the content of magnesium in the concentrate, which causes a significant increase in energy consumption in pyrometallurgical processing of the concentrate. The use of polymer reagents containing sulfo groups seems to be a promising area of research. However, only lignosulfonates have been studied so far in this field. The question of the effectiveness of the depressing effect of other polymer sulfonates including polystyrene sulfonates (PSS), and their comparison with polysaccharides used in industrial conditions remains unclear. The purpose of this work is to study the depressing effect of PSS on the performance of bulk flotation of copper-nickel ores. Research objectives: to experimentally compare the effectiveness of the depressing effect of PSS and a reagent from the polysaccharide class on MS; to determine the modes of PSS use to reduce the magnesium content in the concentrate without significantly reducing the recovery of copper and nickel into the bulk concentrate; to establish the effect of molecular weight and the method of obtaining PSS samples on the effectiveness of their depressing effect. Laboratory experimental studies were carried out on the bulk flotation of copper-nickel ores from the Kola Peninsula, containing 15.7% of magnesium, 0.44% of nickel and 0.25% of copper. The effect of the following polymer anionic reagents on the flotation was studied: PSSs with molecular weight ranging from 89,000 to 208,000 g/mol; polyanionic cellulose (PAC-N) was used for comparison. To increase the effectiveness of these reagents, magnesium chloride was previously added. It was found that the lowest magnesium content in the concentrate of 14.7% was achieved using a composition of magnesium chloride and PSS against 16.7% without the depressants. It was shown that PSS provides a higher recovery of copper (by 7%) and nickel (by 8%) into the concentrate than when using PAC-N, since PSS, unlike polysaccharides, does not form chelate complexes with these metals. It was also shown that for PSS samples, the molecular weight within these limits has virtually no effect on the studied ore flotation performance. New scientific knowledge has been obtained about the effect of the consumption and properties of PSS on the flotation performance. It has been shown that the practical use of this class of reagents is advisable for the flotation of copper-nickel ores with a high magnesium content in cases where it is necessary to achieve the maximum possible decreasing the content of this element in the concentrate without significantly reducing the recovery of copper and nickel.

Keywords

For citations:

Lavrinenko A.A., Golberg G.Yu., Kuznetsova I.N., Lusinyan O.G., Tverskoy V.A. Application of polystyrene sulfonates for the depression of magnesium-containing silicates in copper-nickel ore flotation. Mining Science and Technology (Russia). 2025;10(3):280-288. https://doi.org/10.17073/2500-0632-2025-06-419

Application of polystyrene sulfonates for the depression of magnesium-containing silicates in copper-nickel ore flotation

Introduction

The current stage of mining industry development is characterized by the involvement of relatively lean copper-nickel ores in processing [1–4]. A significant problem in the flotation of such ores is the presence of magnesium–containing silicate minerals (MS), including talc, serpentinite, and a number of others [5, 6]. As a result of the extraction of these silicates into the concentrate, the content of harmful impurities, especially magnesium, increases. This, in turn, has an adverse effect on the subsequent processes of pyrometallurgical processing of the concentrate. For instance, according to [7], the effect of MS on the processing of nickel sulfide concentrate consists in increasing energy consumption, increasing equipment wear, and growing the amount of sulfur dioxide atmospheric emission. This makes the problem of MS depression in copper–nickel ore flotation processes rather relevant.

Lowering MS recovery into flotation concentrate is achieved by using depressants that change the surface properties of these minerals by reducing the contact angle and/or increasing the negative surface charge. As a result, a potential barrier is created between a MS particle and an air bubble, which prevents the formation of a flotation complex and its extraction into the concentrate.

To date, various methods for depression of MS, mainly talc and serpentinite, have been developed. The first one is characterized by natural hydrophobicity due to the peculiarities of the crystal structure: weakly polar Si–O bonds predominate on the basal surface, which constitutes about 90% of the total surface of this mineral [8]. Therefore, the contact angle is relatively high, from 60 to 90o [9, 10]. Unlike talc, serpentinite is more hydrophilic, but its surface charge in acidic, neutral, and alkaline media (up to pH 11–12) is positive [11]. As a result of the mutual attraction of negatively charged sulfide particles and positively charged serpentinite particles, the latter are extracted into flotation concentrate. In this regard, various methods are used for talc and serpentinite depression.

Polysaccharides including carboxymethylated starches and celluloses (CMS and CMC, respectively), have become popular as talc depressants [12, 13]. They are characterized by a strong depressing effect not only on silicates, but also on sulfide minerals [14], i.e. low selectivity. Studies carried out at the IPKON RAS have shown that a domestically produced CMC sample manufactured under the PAC–N brand name (low molecular weight polyanionic cellulose) has a higher depressing capability against MS than foreign samples of reagents of the same class [15]. It is known that the effectiveness of CMC increases when combined with liquid glass, both in acidified [16] and in neutral form [17]. The papers [18, 19] have shown the possibility of effective depression of talc by lignosulfonates with the preliminary addition of calcium cations. The mechanism of depression in this case consists in reducing the hydrophobicity of talc under the influence of strong anionic sulfonate groups. At the same time, calcium cations contribute to an increase in the adsorption capacity of talc in relation to lignosulfonates. It is noted that the adsorption of lignosulfonate on chalcopyrite is lower than that on talc; this suggests that polymer reagents containing sulfo groups are selective in their depressing effect on talc. The effect of other polymer sulfonates on the flotation of copper–nickel ores has not yet been studied both in Russia and abroad.

The results of monomineral talc flotation showed the depressing effect of sodium polystyrene sulfonates (PSS), which is slightly weaker than that of CMC and increases when magnesium or aluminum cations are pre–added [20].

For the depression of serpentinite during the flotation of copper–nickel ores, liquid glass in particular is used [21]. Its effect is mainly to neutralize the positive surface charge of this mineral by silicate anions. It is also known about the use of graphene oxide, which can selectively aggregate serpentinite [7, 22], organic phosphates, in particular sodium phytate [6], and acid treatment [23].

An analysis of the literature sources made it possible to establish the following:

- Modern methods of MS depression using polysaccharides, liquid glass, and other reagents make it possible in some cases to effectively reduce the magnesium content in the concentrate, but at the same time reduces, and in some cases significantly, the recovery of copper and nickel into the bulk flotation concentrate due to the depression of the sulfides of these metals;

- to date, the effectiveness of the depressing effect of polymer sulfonates and polysaccharides has not been compared;

- The effect of PSS on monomineral talc flotation has been studied, but it is unclear what effect PSS has on the flotation performance of copper–nickel ore containing MS, including on the concentrate yield, its magnesium content, and the recovery of copper and nickel.

The purpose of this work is to study the depressing effect of polystyrene sulfonates on the performance of bulk flotation of copper–nickel ore.

Research objectives:

- experimental comparison of the effectiveness of the depressing effect of PSS and a reagent from the polysaccharide class on MS;

- determining the modes of PSS use that reduce the magnesium content in the concentrate without significantly reducing the recovery of copper and nickel into the bulk concentrate;

- establishing the effect of molecular weight and the method of producing PSS samples on the effectiveness of their depressing effect.

To achieve these goals, it was planned to conduct experimental studies on the flotation of copper–nickel ores with reagent compositions to achieve the lowest magnesium content in the concentrate without significantly reducing the recovery of copper and nickel.

Procedure of experiments

The studies were carried out with a sample of copper–nickel ore from the Kola Peninsula. The elemental composition of the ore according to X–ray fluorescence analysis was as follows: Si – 17.2, Mg – 15.8, Fe – 12.9, Al – 2.5, Ca – 2.0, S – 1.13, Ni – 0.44, Cu – 0.25, Cr – 0.20 %. X–ray phase analysis revealed the following minerals in the ore: antigorite, chlorite, amphibole, olivine, spinel minerals, pentlandite, violarite, pyrrhotite, chalcopyrite, chalcophyllite, etc.

The experiments were carried out on a laboratory flotation machine with a cell volume of 150 cm3 according to a scheme that involves sequential rougher and recleaner flotation of the initial ore sample with separate supply of reagents and appropriate stirring. A sample of an aqueous suspension of the initial ore (pulp) was prepared: the weight of the sample was 45 g, pH = 9. After mixing for 60 seconds, the reagents were sequentially fed in the following order: a depressant, collectors, and a frother. The contact time of each reagent with the pulp was 60 sec with permanent stirring. The froth product was sampled every 15 seconds. After 300 seconds of rougher flotation, a recleaner flotation of the cell product was carried out, with adding the above reagents sequentially in an amount equal to 40% of the consumption in the rougher flotation. The recleaner flotation lasted 180 sec. The combined concentrate and tailings were weighted. The grades of copper, nickel, magnesium, and silicon in them were determined by X–ray fluorescence analysis. The studies were carried out using parallel experiments. Statistical analysis showed that the discrepancy between the results in a pair of the parallel experiments was approximately ±0.8% (relative).

The effectiveness of the depressing effect of the studied reagents was determined based on the yield of concentrate γ, the recovery of copper εCu and nickel εNi into the concentrate; the grades of these metals (βCu and βNi, respectively) in the concentrate, as well as the content of magnesium βMg; the Hancock–Luyken criterion (HL), which takes into account the values of ε, γ, as well as the grades of copper and nickel in the initial ore α:

HL = (ε - γ)/(100 - α). (1)

Laboratory samples of linear sodium PSS, which were not previously used in ore flotation, were used as MS polymer depressants. The properties of the studied PSS samples are presented in Table 1. For comparison, carboxymethylated cellulose PAC–N manufactured by Policell CJSC with an average viscosity molecular weight of about 116,000 g/mol and a gamma number of 90% was also used as a polymer depressant.

Table 1

Properties of the studied polystyrene sulfonates

Reagent symbol | Medium viscosity molecular weight (MW), g/mol | Chain growth regulator; concentration, mol/l |

L–50 | 97,000 | Isopropanol; 0.3 |

L–51 | 89,000 | Isopropanol; 0.9 |

L–54 | 89,000 | Glycine, 0.9 |

L–55 | 96,000 | Glycine, 0.9 |

L–5 | 93,000 | Trimethylamine; 0.008 |

L–6 | 208,000 | Trimethylamine; 0.041 |

L–7 | 176,000 | Trimethylamine; 0.082 |

Potassium butyl xanthate (PBX) and dibutyl dithiophosphate (DBTP) were used as collectors. To increase the effectiveness of the depressing effect of the polymer reagents, MgCl2 was added, since the Mg2+ cation, according to [20], contributes to talc depression with the use of PSS.

Findings and Discussion

In the ore flotation without depressants but with the use of PBX and DBTP, the highest copper and nickel recoveries were achieved at PBX consumption of 112 g/t and that of DBTP of 84 g/t: 89.6% and 85.5%, respectively. This reagents composition was used in further experiments.

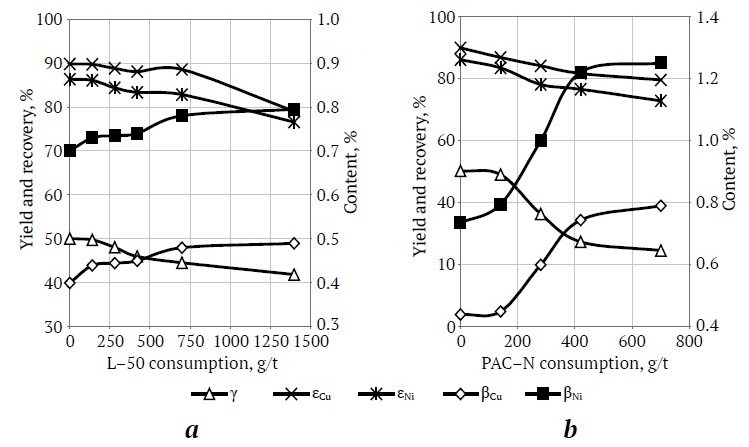

The depressing effect of polystyrene sulfonates on MS was studied using the example of the effect of L–50 in comparison with PAC–N (Fig. 1).

Fig. 1. The effect of depressant consumption on ore flotation: a – L–50; b – PAC–N

In Fig. 1, one can see that the optimal consumption of L–50 depressant is 700 g/t. At this consumption, the concentrate yield decreases from 49.8% to 44.6%. At the same time, copper recovery decreases from 89.7% to 88.5%, and nickel recovery, from 86.1% to 82.8%. A further increase in the depressant consumption leads to a significant decrease in the recovery of the metals into the concentrate. For instance, at L–50 consumption of 1,400 g/t, copper recovery into the concentrate was 79%, and that of nickel, 76.6%.

The data presented in Fig. 1, b show that effective results were obtained at a PAC–N consumption of 420 g/t. Under this flotation regime, copper recovery into the concentrate was 81.7%, and that of nickel, 76.6%, while the grades in the concentrate increased from 0.4 to 0.74% Cu and from 0.7 to 1.22% Ni.

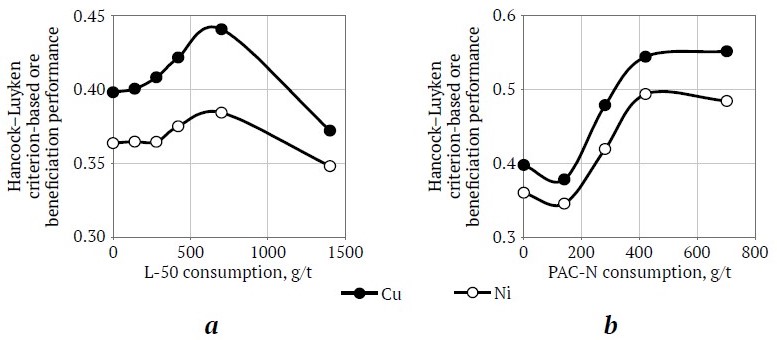

An analysis of the beneficiation performance when using various depressants in accordance with the Hancock–Luyken (HL) criterion showed (Fig. 2) that the maximum HL criterion for both copper and nickel is achieved at L–50 and PAC–N consumption of 700 and 420 g/t, respectively.

Fig. 2. The effect of depressant consumption on the ore beneficiation performance according to Hancock–Luyken criterion:

a – L–50; b – PAC–N

Thus, the optimal consumption of the depressants was 700 g/t for L–50 and 420 g/t for PAC–N, that corresponded to relatively low metal losses in the course of flotation. These values were adopted for further research to determine the most effective modes of the use of these reagents.

According to a number of studies, for example [20], the effectiveness of the depressing effect of polymer reagents on MS increases when multicharged cations, in particular Mg2+, are pre–added. Therefore, in this study, the effect of the addition of this cation on the depressing action of PSS and PAC–N was investigated.

The results of experiments using L–50 and the preliminary addition of MgCl2 at a consumption of 0 to 70 g/t showed that the lowest bulk concentrate yield was achieved at a consumption of MgCl2 of 7 g/t through reducing the floatability of rock minerals due to hydrophilization of their surfaces. This reduces the magnesium content in the concentrate by approximately 2.0% compared to the regime without the use of the depressants.

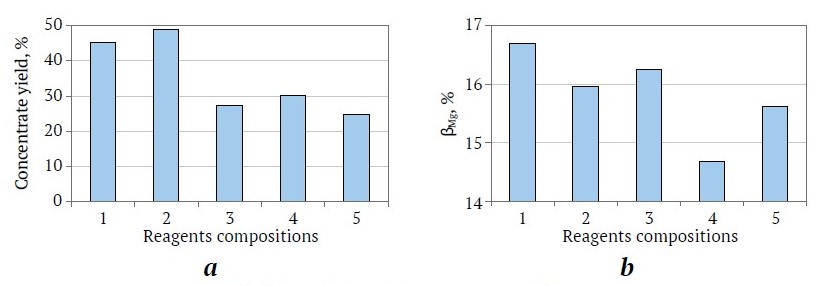

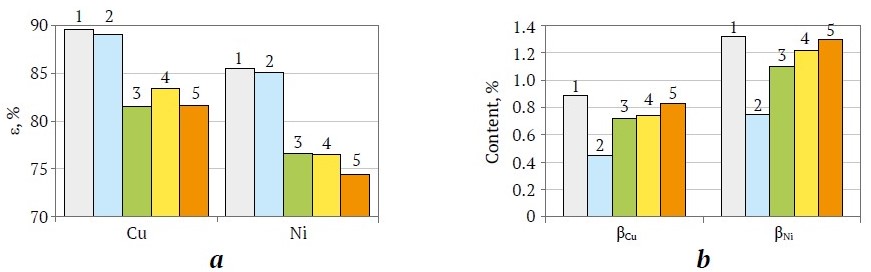

Figs. 3 and 4 show data characterizing the ore flotation with the following compositions of the studied depressants: 1 – without depressants; 2 – L–50, 700 g/t; 3 – PAC–N, 420 g/t; 4 – MgCl2, 7 g/t + L–50, 700 g/t; 5 – MgCl2, 7 g/t + PAC–N, 420 g/t.

Fig. 3. The effect of depressant compositions:

a – on the concentrate yield; b – on the magnesium content in the concentrate

Fig. 4. The effect of depressant compositions:

a – on the recovery of copper and nickel into the concentrate; b – on the content of copper and nickel in the concentrate

The data in Fig. 3, a show that the lowest values of γ, approximately 27% and 25%, are achieved by using PAC–N and MgCl2 in combination with PAC–N, respectively, that indicates the latter's high depressing capacity. At the same time, L–50, if used individually, even slightly increases the γ value that may be due to the manifestation of some flocculating ability of this reagent.

In the case of preliminary addition of MgCl2, for L–50, the γ value decreases from 49 to 30%, and for PAC–N, from 27 to 25%. It is obvious that the difference in γ values with the use of MgCl2 and a polymer reagent compared to the individual use of the latter for L–50 is 19% versus 2% for PAC–N. This is probably due to the fact that L–50 sulfo groups are more strongly attracted to the surface of minerals modified by Mg2+ ions than PAC–N carboxyl groups.

Fig. 3, b shows that composition No. 4 (MgCl2 and L–50) provides the lowest magnesium content in the concentrate: 14.7% versus 16.7% for No. 1 (without depressants) and 15.6% for No. 5 (MgCl2 and PAC–N). Overall, the magnesium content in the concentrate is reduced by about 2%.

Fig. 4, a shows downtrend of the recovery values ε with the use of the depressants. At the same time, L–50 reduces the recovery to a lesser extent than PAC–N, as can be seen from the comparison of compositions Nos. 2, 3 and Nos. 4, 5: in the case of individual use of the depressants, L–50 reduces the recovery of copper and nickel compared to the experiment without depressants by 0.5 and 0.4%, respectively, against 8.1 and 8.9% for PAC–N at its effective consumption. When MgCl2 is first added to L–50, the recovery of copper and nickel decreases by 6.2% and 9.0%, respectively, compared to the experiment without the depressants; for PAC–N, by 7.9 and 11.1%, respectively. The data in Fig. 4, b show that the least decrease in β is observed when MgCl2 and PAC–N are used.

Thus, L–50 has an effect on MS in the presence of MgCl2 only, and, at the same time, provides less effective depression as compared to PAC–N. A comparative analysis of the mechanisms of interaction between PSS and PAC–N with the MS surface, taking into account literature data, showed that for linear PSS macromolecules characterized by a smaller Kuhn segment length (4 nm versus about 20 nm), and, therefore, higher flexibility than PAC–N, some of the anionic groups are distant from the surface, or shielded, and therefore do not participate in the formation of surface charge. Unlike PSS, a PAC–N macromolecule has a wave–like, close to flat shape and is located along the mineral surface [24]. As a result, most of the anionic groups participate in the formation of surface charge. In contrast to PSS, a PAC–N macromolecule also contains hydrogen atoms capable of forming hydrogen bonds with electronegative atoms on the MS surface. This presumably determines the weaker effect of PSS on these minerals compared to CMC.

At the same time, polysaccharides, in contrast to PSS, form chelated complexes with copper and nickel [25, 26], and this leads to a lower recovery of these metals into the concentrate when using PAC–N compared to L–50.

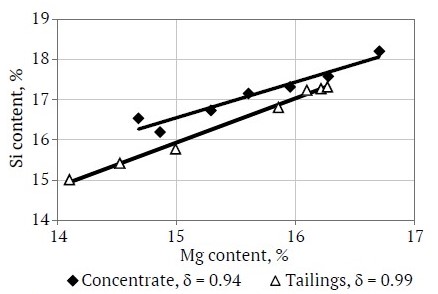

It was also found that the contents of silicon and magnesium in both concentrate and tailings are correlated with very high values of the determination coefficient δ, as can be seen in Fig. 5; this confirms that magnesium is mainly concentrated in silicate minerals.

Fig. 5. Correlation between silicon and magnesium content in flotation products

The attempts to use other PSS samples for MS depression, which differ from L–50 in MM values, as well as by reagents for regulating chain growth, showed very similar recovery and content values in the bulk concentrate:

- for Cu – 85.7–87.0% and 0.48–0.59%, respectively;

- for Ni – 75.2–80.4% and 0.74–0.90%, respectively.

The analysis of the dependences of γ, as well as ε and β values for copper and nickel on the MM of these PSS samples showed that the determination coefficient δ does not exceed 0.21; this indicates that the MM value in the range from 89,000 to 208,000 g/mol has virtually no effect on the results of the ore flotation with the listed PSS samples. The reagents used to regulate chain growth during the polymerization of PSS (isopropanol, glycine, trimethylamine, see Table 1) also did not had an effect on the results.

Practical application

Based on the experimental data obtained, the use of PSS is recommended for the flotation of copper–nickel ores with a high magnesium content in cases where it is necessary to achieve the greatest possible restriction of the content of this element in the bulk concentrate without significantly reducing the recovery of copper and nickel, especially when the use of polysaccharide depressants does not significantly reduce the magnesium content in the concentrate and/or there is a significant decrease in the valuable metal recovery. PSS consumption is several hundred grams per ton; it is determined experimentally for a specific ore. Before applying PSS, it is advisable to add aqueous solutions of magnesium compounds so that the consumption of Mg2+ ions is about 5–10 g/t. At the same time, the expected magnitude of reducing the recovery of copper and nickel into the bulk concentrate will be lower compared to the use of CMC. This will make it possible to obtain an economic effect by reducing energy consumption for the subsequent pyrometallurgical processing of the concentrate.

It also seems appropriate to conduct separate studies with linear PSS samples with a MM of more than 1 million g/mol.

Conclusions

Based on experimental studies on bulk flotation of copper–nickel ore using sodium polystyrene sulfonate and PAC–N carboxymethyl cellulose, new scientific knowledge was obtained about the effect of the consumption and properties of polystyrene sulfonates on flotation performance.

1) It was found that in terms of reducing the concentrate yield, polystyrene sulfonate generally has a weaker depressing effect on magnesium–containing silicates than PAC–N. However, when using polystyrene sulfonate, the magnesium content in the concentrate is approximately 1% lower than when using PAC–N that allows reducing energy consumption in the course of the subsequent pyrometallurgical processing of the concentrate. Polystyrene sulfonate also provides a higher recovery of copper (up to by 7%) and nickel (up to by 8%) into the concentrate than when using PAC–N, since it does not form chelate complexes with these metals unlike polysaccharides.

2) It was found that the most effective MS depression is achieved by sequential applying magnesium chloride with a consumption of 7 g/t and polystyrene sulfonate with a consumption of 700 g/t. At the same time, the magnesium content in the concentrate is reduced by 2% compared to the flotation without depressants that justifies the use of this composition.

3) It was found that for the polystyrene sulfonate samples, the molecular weight ranging 89,000 to 208,000 g/mol, as well as the reagents used in the course of the synthesis process to regulate chain growth, have virtually no effect on the flotation results.

4) It has been shown that the practical use of PSS is advisable for the flotation of copper–nickel ores with a high magnesium content in cases where it is necessary to achieve the maximum possible decreasing the content of this element in the concentrate without significantly reducing the recovery of copper and nickel.

References

1. Boyarko G. Yu., Lapteva A. M., Bolsunovskaya L. M. Mineral resource base of Russia’s copper: current state and development prospects. Mining Science and Technology (Russia). 2024;9(4):352–386. https://doi.org/10.17073/2500-0632-2024-05-248

2. Svetlov A. V., Krasavtseva E. A., Goryachev A. A., Potorochin E. O. The challenge in mineral processing for low-grade ores and man-made waste: how to reduce the negative environmental impact from the mining industry? Bulletin of the Kola Science Centre of the Russian Academy of Sciences. 2020;12(3):21–33. https://doi.org/10.37614/2307-5228.2020.12.3.003

3. Gan F., Gao L., Dai H., et al. Study on beneficiation technology for rational utilization of low-grade copper nickel symbiotic ore. Journal of Mining Science. 2023;59(5):828–839. https://doi.org/10.1134/S1062739123050150 (Orig. ver.: Gan F., Gao L., Dai H., et al. Study on beneficiation technology for rational utilization of low-grade copper nickel symbiotic ore. Fiziko-Texhnicheskiye Problemy Razrabbotki Poleznykh Iskopaemykh. 2023;(5):140–151. (In Russ.) https://doi.org/10.15372/FTPRPI20230515)

4. Stepanova K. D., Kazantseva M. I. Impact of material composition of copper-nickel ores on their processing. Mining Industry Journal. 2021;(S5–2):17–23. (In Russ.)

5. Xie J., Sun W., Zhao K., et al. Upgrading of talc-bearing copper-nickel sulfide ore by froth flotation using sodium phytate as depressant. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 2024;687:133561. https://doi.org/10.1016/j.colsurfa.2024.133561

6. Zhao K., Yan W., Wang X., et al. Effect of a novel phosphate on the flotation of serpentine-containing copper-nickel sulfide ore. Minerals Engineering. 2020;150:106276. https://doi.org/10.1016/j.mineng.2020.106276

7. Yin F., Zhang Ch., Yu Y., et al. Review on the challenges of magnesium removal in nickel sulfide ore flotation and advances in serpentinite depressor. Minerals. 2024;14(10):965. https://doi.org/10.3390/min14100965

8. Dikmen S., Ersoy B., Dikmen Z. Adsorption behaviour of ionic and non-ionic surfactants onto talc a naturally hydrophobic mineral-a comparative study. Eskişehir Technical University Journal of Science and Technology A – Applied Sciences and Engineering. 2020;21:139–152. https://doi.org/10.18038/estubtda.829712

9. Douillard J. M., Zajac J., Malandrini H., Clauss F. Contact angle and film pressure: study of a talc surface. Journal of Colloid and Interface Science. 2002;255(2):341–351. https://doi.org/10.1006/jcis.2002.8611

10. Galet L., Goalard C., Dodds J.A. The importance of surface energy in the dispersion behaviour of talc particles in aqueous media. Powder Technology. 2009;190(1–2):242–246. https://doi.org/10.1016/j.powtec.2008.04.086

11. Binbin Li, Guofan Zhang, Dezhi Liu, Jianhua Chen. Selective alteration mechanisms of sodium tripolyphosphate towards serpentine: Implications for flotation of pyrite from serpentine. Journal of Molecular Liquids. 2022;368(Part A):120687. https://doi.org/10.1016/j.molliq.2022.120687

12. Krasavtseva E. A., Goryachev A. A. Review of methods of talc depression at the flotation of copper-nickel ores. Proceedings of the Kola Science Centre of the Russian Academy of Sciences. 2019;10(6–1):149–154. (In Russ.) https://doi.org/10.25702/KSC.2307-5252.2019.6.020

13. Liao R., Deng J., Lai H., et al. An overview of technologies and selective depressing agents for separating chalcopyrite and talc. International Journal of Metallurgical & Materials Engineering. 2018;4:146. https://doi.org/10.15344/2455-2372/2018/146

14. Huang R., Liu J., Yang D., et al. Depression effect of CMC on sulfide ore flotation and its influencing factors. Chinese Journal of Engineering. 2024;46(4):627–636. (In Chinese) https://doi.org/10.13374/j.issn2095-9389.2023.02.28.006

15. Lavrinenko A. A., Kuznetsova I. N., Lusinyan O. G., Golberg G. Yu. Utilizing Russian polymer anion active depressants in the flotation of out-of-balance talcose copper nickel ore. Izvestiya. Non-Ferrous Metallurgy. 2023;29(5):5–14. https://doi.org/10.17073/0021-3438-2023-5-5-14

16. Xue J., Tu H., Shi J., et al. Enhanced inhibition of talc flotation using acidified sodium silicate and sodium carboxymethyl cellulose as the combined inhibitor. International Journal of Minerals, Metallurgy and Materials. 2023;30(7):1310–1319. https://doi.org/10.1007/s12613-022-2582-5

17. Lavrinenko A. A., Kuznetsova I. N., Golberg G. Yu., Lusinyan O. G. Joint use of sodium silicate and polysaccharides in the flotation of talcose copper-nickel ores. Izvestiya. Non-Ferrous Metallurgy. 2024;(2):5–15. https://doi.org/10.17073/0021-3438-2024-2-5-15

18. Fu Y., Zhu Zh., Yao J., et al. Improved depression of talc in chalcopyrite flotation using a novel depressant combination of calcium ions and sodium lignosulfonate. Colloids and Surfaces A. 2018;558:88–94. https://doi.org/10.1016/j.colsurfa.2018.08.056

19. Mai Q., Zhou H., Ou L.. Flotation separation of chalcopyrite and talc using calcium ions and calcium lignosulfonate as a combined depressant. Metals. 2021;11(4):651. https://doi.org/10.3390/met11040651

20. Lavrinenko A. A., Kuznetsova I. N., Gol'berg G. Yu. Depression of flotation-sensitive silicates using polymeric anion active reagents. Journal of Mining Science. 2024;60(6):1022–1028. https://doi.org/10.1134/S1062739124060176 (Orig. ver.: Lavrinenko A. A., Kuznetsova I. N., Gol'berg G. Yu. Depression of flotation-sensitive silicates using polymeric anion active reagents. Fiziko-Texhnicheskiye Problemy Razrabbotki Poleznykh Iskopaemykh. 2024;(6):160–167. (In Russ. https://doi.org/10.15372/FTPRPI20240617)

21. Molifie A., Becker M., Geldenhuys S., McFadzean B. Investigating the reasons for the improvement in flotation grade and recovery of an altered PGE ore when using sodium silicate. Minerals Engineering. 2023;195:108024. https://doi.org/10.1016/j.mineng.2023.108024

22. Cao J., Tian X., Luo Y., Hu X. The effect of graphene oxide on the slime coatings of serpentine in the flotation of pentlandite. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 2017;522:621–627. https://doi.org/10.1016/j.colsurfa.2017.03.043

23. Feng B., Lu Y., Feng Q., et al. Mechanisms of surface charge development of serpentine mineral. Transactions of Nonferrous Metals Society of China. 2013;23(4):1123–1128. https://doi.org/10.1016/S1003-6326(13)62574-1

24. Wang J., Somasundaran P. Adsorption and conformation of carboxymethyl cellulose at solid-liquid interfaces using spectroscopic, AFM and allied techniques. Journal of Colloid and Interface Science. 2005; 291(1): 75–83. https://doi.org/10.1016/j.jcis.2005.04.095

25. El-Saied H., Basta A. H., Hanna A. A., El-Sayed A.M. Semiconductor properties of carboxymethyl cellulose-copper complexes. Polymer-Plastics Technology and Materials. 1999;38(5):1095–1105. https://doi.org/10.1080/03602559909351633

26. Hosny W. M., Abdel Hadi A. K., El-Saied H., Basta A. H. Metal chelates with some cellulose derivatives. Part III. Synthesis and structural chemistry of nickel (II) and copper (II) complexes with carboxymethyl cellulose. Polymer International. 1995;37(2):93–96. https://doi.org/10.1002/pi.1995.210370202

About the Authors

A. A. LavrinenkoRussian Federation

Anatoly A. Lavrinenko – Dr. Sci. (Eng.), Chief Researcher, Head of the Laboratory

Moscow

G. Yu. Golberg

Russian Federation

Grigory Yu. Golberg – Dr. Sci. (Eng.), Leading Researcher

Moscow

I. N. Kuznetsova

Russian Federation

Irina N. Kuznetsova – Cand. Sci. (Eng.), Senior Researcher

Moscow

Scopus ID 57201564209

O. G. Lusinyan

Russian Federation

Oganes G. Lusinyan – Cand. Sci. (Eng.), Lead Engineer

Moscow

Scopus ID 57201648662

V. A. Tverskoy

Russian Federation

Vladimir A. Tverskoy – Dr. Sci. (Chem.), Professor

Moscow

Scopus ID 6604012434

ResearcherID H-8042-2017

Supplementary files

Review

For citations:

Lavrinenko A.A., Golberg G.Yu., Kuznetsova I.N., Lusinyan O.G., Tverskoy V.A. Application of polystyrene sulfonates for the depression of magnesium-containing silicates in copper-nickel ore flotation. Mining Science and Technology (Russia). 2025;10(3):280-288. https://doi.org/10.17073/2500-0632-2025-06-419

JATS XML