Scroll to:

Justification of the prospects for developing gas-bearing sites in the Karaganda coal basin

https://doi.org/10.17073/2500-0632-2025-06-425

Abstract

The relevance of this study is due to the current need to meet energy resources demand. A promising option worth considering is the production of methane gas from unconventional sources, whose reserves significantly exceed those of conventional deposits. Objective: to evaluate gas-bearing sites and justify the principles for rating their prospects based on an analysis of geological and technological factors affecting the process of gas release from coal seams. To achieve this goal, the study examined the Karaganda coal basin as a promising district for methane gas extraction, divided into five sites: Tenteksky, Saransky, Promyshlenny, Sherubainurinsky, Taldykuduksky. The most gas-bearing seams (reservoirs), with depth of occurrence ranging from 420 to 635 m, were studied. As a result of the study, first- and second-level coal seam zones were identified for methane extraction from coal seams. The parameters used to identify these zones were: depth of occurrence, permeability, and desorption of coal in a seam. At a depth of 250–300 m, gas permeability of the seams was recorded within the range of 10–15 millidarcy (mD). It was established that gas permeability decreases with increasing depth, and at a depth of 600–700 m, it amounts to hundredths and thousandths of a millidarcy. To determine the gas content of coal seams, representative samples were taken to characterize the gas content of coal seams from K20 to K1 across the entire area of the mining allotment under investigation. Sites in fault zones were not considered. They are classified as unrepresentative due to gas losses exceeding 30%. It has been established that the increase in gas content (methane content) in the Karaganda basin follows the ascending branch of a S-shaped curve and is described by the Langmuir equation. Methane resources in all host rocks have been determined based on a minimum methane content of 1 m3/t, and in claystones and siltstones with disseminated coal inclusions, based on a methane content of 4–5 m3/t of rock. At the same time, it has been established that in order to make a rough estimate of the resources, it is necessary to have data on total and effective porosity, water saturation of sandstones, and other factors. For the first time in the Karaganda coal basin, an integrated system for assessment of sites in terms of the potential of methane extraction has been implemented, incorporating more than 10 factors. Unlike previous studies, where assessments were made based on individual characteristics (depth, gas content, permeability), this paper proposes a generalized scoring method that allows for quantitative comparison of sites and prediction of methane production performance. Besides, the study novelty comprises the dependencies of Langmuir coefficients on fusinite content and temperature established in the study, which had not previously been applied to local coals. During the study, first- and second-order zones were identified in terms of methane production prospects; quantitative dependencies of gas content on depth, coal rank (stage of maturation), and petrographic composition were established; sites with the greatest commercial production potential were identified, and a methodology for the criterion-based assessment of sites was developed.

Keywords

For citations:

Mussin R.A., Nemova N.A., Akhmatnurov D.R., Zamaliyev N.M., Reshetnyakov E.D., Reznik A.V. Justification of the prospects for developing gas-bearing sites in the Karaganda coal basin. Mining Science and Technology (Russia). 2025;10(4):321–337. https://doi.org/10.17073/2500-0632-2025-06-425

Justification of the prospects for developing gas-bearing sites

in the Karaganda coal basin

Introduction

Currently, Kazakhstan's fuel and energy sector is facing the problem of depletion of hydrocarbon reserves such as natural gas and oil. In addition to the constantly deteriorating conditions for extraction, the structure of existing reserves is also changing, i.e., the share of hard-to-recover reserves is growing. For example, global natural gas resources are already unable to meet the needs of the population, as the most accessible (easily extractable) deposits are largely depleted. At the same time, China, the United States, and Russia are the leaders in terms of primary energy production (according to Enerdata, 2024). Natural gas, crude oil, uranium, and coal constitute the main share of extracted natural resources. Meanwhile, coal accounts for the largest share, 15.9 billion tonnes of oil equivalent, followed by uranium, 10.3 billion tonnes of oil equivalent, while oil accounts for the smallest share, 5.2 billion tonnes of oil equivalent, followed by natural gas, 3.5 billion tonnes of oil equivalent.

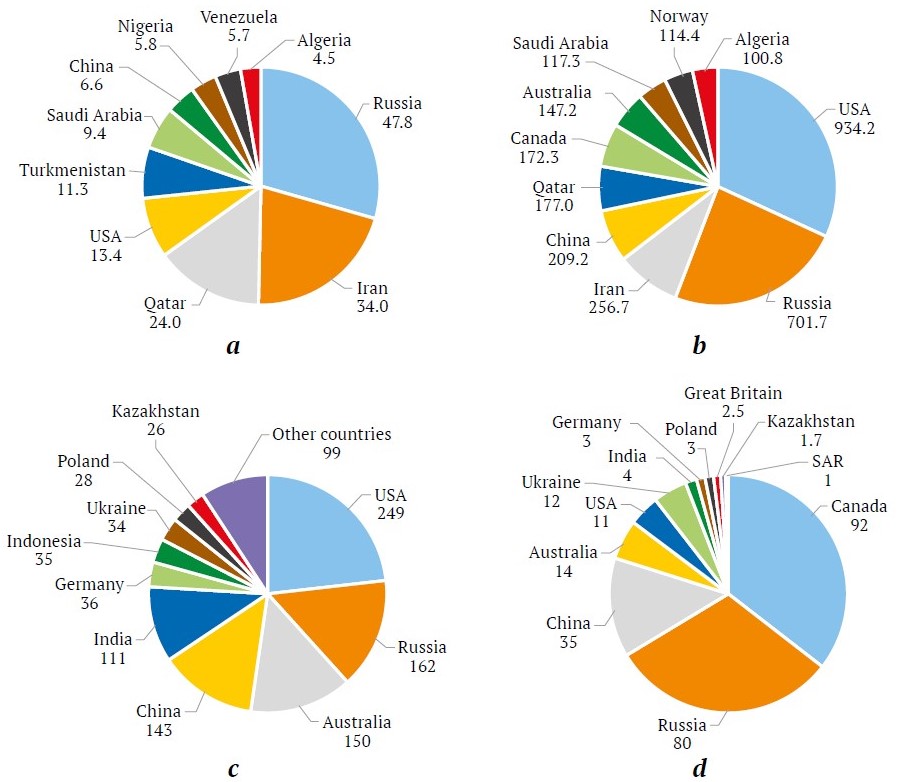

Fig. 1 shows global reserves (a) and production volumes (b) of natural gas at the beginning of 2023, estimated by OPEC at 207.9 trillion m3. At the same time, according to the US Energy Information Administration, global oil reserves amounted to 1.7 trillion barrels as of 2023. However, energy needs can be met by extracting methane gas from unconventional sources, whose reserves significantly exceed those of conventional deposits. According to the International Energy Agency, global coal production in 2033 will amount to 8.7 billion tons, with reserves of hard coal at 9.5 trillion tons and those of lignite at 4.9 trillion tons. The presence of significant reserves indicates the presence of large amounts of methane in the subsoil, which mean that projects for their assessment and subsequent extraction may prove promising (Fig. 1, c, d). At the same time, according to data from the International Energy Agency, global methane production from coal seams could reach 200 billion m3 by 2035. Statistical reports from IEA1 also show that global predicted reserves of gas from unconventional sources exceed those in conventional deposits by 2.2 times, with Canada, Russia, and the US leading in terms of the reserves, and the US leading in terms of production2.

Fig. 1. World reserves as of 2023:

a – natural gas, trillion m3; b – natural gas production volumes, billion m3;

b – coal, billion t; c – coal seam methane, trillion m3

Unconventional gas reserves significantly exceed those of conventional deposits and, according to data from the International Energy Agency3, amount to 921 trillion m3. Meanwhile, the volume of methane in coal seams worldwide is estimated at 256 trillion m3, which accounts for more than 19% of total gas resources (Table 1).

Table 1

Structure of Global Gas Resources [1]

Types of gas resources | Volume of gas resources, trillion m3 | Shares of gas resources by type, % |

1 Conventional gas resources | 405 | 30.54 |

2 Unconventional gas resources | 921 | 69.46 |

2.1 Tight sandstone gas | 209 | 15.76 |

2.2 Coal seam methane | 256 | 19.31 |

2.3 Shale gas | 456 | 34.39 |

Total gas resources | 1,326 | 100.00 |

Various techniques for extracting methane from coal seams are being used quite successfully in certain countries [2, 3]. Practically all over the world, coal seam methane (CSM) extraction has become strategically important both in the context of preliminary (advance) degassing of methane-bearing seams to improve mining safety and as an independent area of subsoil use – the extraction of unconventional hydrocarbons, namely coal seam methane.

1 International Energy Agency, World Energy Outlook. 2023.

2 Coal bed methane: Prospects for the development of unconventional hydrocarbons in the CIS. 2011. URL: https://gaap.ru/articles/Metan-ugolnyh-plastov/

3 International Energy Agency, World Energy Outlook. 2023.

Problem definition

For a long time, methane contained in coal seams was considered a harmful factor that reduced the performance of coal mining. A significant portion of the costs associated with organizing coal mining is directed toward creating safe working conditions. This includes the costs of measures to monitor the gas conditions in a mine, ventilate mine workings, purchase equipment to suppress dust and ensure explosion safety, emergency monitoring and warning systems, search and rescue equipment, communication equipment and alarms, as well as degassing of coal-rock mass. Equally important are the costs of operating drainage, electricity, water, and heating systems, purchasing specialized transport, tools, and materials for safe blasting, and other measures. It should be noted that coal seam degassing opens up the feasibility of using methane as a by-product natural resource4. To date, in order to improve the environmental situation and reduce methane emissions into the environment, it is necessary to extract methane from coal seams by means of advance degassing. It should also be noted that methane entering the atmosphere leads to the destruction of the ozone layer, and its annual accumulation in the atmosphere is 1–2%, which exceeds the accumulation rate of other gases. However, methane is a good unconventional energy source and can be considered as a component of the country's fuel and energy raw material base. Given that global predicted reserves of coal seam methane (in coal formations) account for more than 19% of total gas reserves and exceed its availability in conventional deposits by 2.2 times, it is necessary to conduct a resource estimation of the gas-bearing sites of the Karaganda coal basin and justify the rating of the prospectivity of these sites based on an analysis of geological and technological factors affecting the process of gas release from coal seams that is the purpose of this study.

In this regard, the following tasks were set: to analyze the current state and global experience in the field of methane extraction from coal seams; to investigate the methane content of coal seams in the Karaganda basin, taking into account the depth of occurrence, geological structure, and coal rank (stage of coal maturation); to establish dependencies between the geological and petrographic characteristics of coal and methane content parameters based on sorption isotherms; to determine, based on the results of pilot-plant tests, the influence of a number of geological and technological factors characterizing the prospects of the sites on methane recoverability; justify the rating of the prospects of the sites based on the established criteria and a scoring system for key indicators; determine the first and second order sites in terms of methane production prospects, taking into account integral indicators.

4 Jaireth S., Huleatt M. B. Australian in situ coal resources. Geoscience Australia, Canberra; 2012. URL: http://pid.geoscience.gov.au/dataset/ga/74097

Research methodology and objects

1. Research Methodology

This study used a set of methods tested and approved in international and domestic practice for studying the gas content of coal seams, including: direct desorption analysis (canister test) to assess actual gas content, construction of sorption isotherms based on the Langmuir model, and petrographic analysis of coals with the determination of vitrinite and fusinite.

Unlike existing approaches, in which the potential of sites is determined on the basis of individual parameters (depth, gas content, permeability), this study uses an integrated methodology developed earlier by the authors, combining 10 key factors that influence methane content and commercial methane recoverability.

The research methodology includes a comprehensive assessment of the gas content of coal seams based on direct desorption analysis (canister test), determination of sorption kinetic parameters using the Langmuir equation, and petrographic analysis of coal. All methods have been tested and approved in international and domestic practice [4–6] and applied at the pilot-plant testing stage at five sites in the Karaganda basin. The novelty of the approach lies in the integrated criterion-based assessment of sites, taking into account a combination of factors: permeability, moisture content, sorption characteristics, volatile-matter yield, and gas pressure. These parameters were used together for the first time to rank sites for the conditions of this basin.

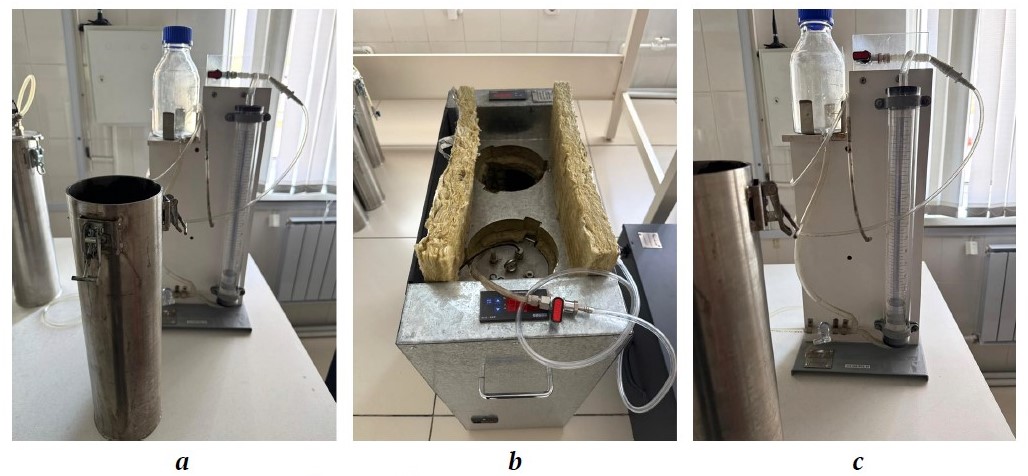

To determine gas content, the desorption method of investigation was used, the canister test, which is used both internationally and in Russia [7]. This choice was based on the possibility of quantitative determining the volume of desorbable and residual gas under various thermobaric conditions that is particularly important for coals from the Karaganda basin of different stage of maturation (coal rank). This method involves sampling coal core from coal seams using removable KG-55 core gas samplers in exploration wells, using a control calculation method, forecasting the methane content of coal seams based on petrographic composition data. Next, gas was extracted from a gas collector, the core receiver with the coal core sample was separated from the core gas sampler and sealed with plugs. After that, the coal core samples were placed into a thermostat set to a temperature equal to the temperature of the seam from which the samples were taken. The volume of desorbed gas was determined using a measuring cylinder and residual gas in coal under three degassing modes until complete gas extraction: first, at a temperature of 60–90 °C, second, during thermal vacuuming with heating to 60–90 °C, and third, after crushing a sample in a ball mill at 60–90 °C and vacuuming. The total gas content was determined as the sum of the volumes of lost, desorbed, and residual gas. The stages of the workflow for determining the volume of desorbed gas are shown in Fig. 2.

Fig. 2. Geokrak Desorption Unit (Poland):

a – container for collecting samples K01; b – installation for creating formation temperature;

c – gas release recording device

Langmuir isotherms, traditionally used in Coal-Seam Methane (CSM) deposit studies, were used to analyze the sorption capacity of coals5. The authors' contribution lies in refining the coefficients of the Langmuir equation for coal seams in the Karaganda basin based on laboratory data, taking into account temperature conditions and petrographic composition (in particular, the contents of fusinite and vitrinite). The proposed approach for the first time integrates desorption, permeability, moisture content, maturation, and petrographic parameters of coal into a single scoring system for comprehensive assessment of site potential that is a development of approaches previously described in [8, 9].

5 Pashin J. C. Geologic heterogeneity and coalbed methane production – experience from the Black Warrior Basin. In: Selected Presentations on Coalbed Gas in the Eastern United States. U.S. Geological Survey Open-File Report 2004-1273. Pp. 61–92.

Jaireth S., Huleatt M. B. Australian in situ coal resources. Geoscience Australia, Canberra; 2012. URL: http://pid.geoscience.gov.au/dataset/ga/74097

2. Sampling

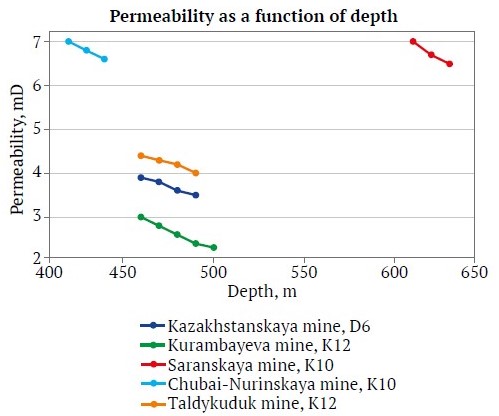

Samples were taken from the study sites with the most gas-bearing seams, which were considered to be representative of the sites. At various depths and several times for the accuracy of the studies conducted to determine the effect of the depth of a seam occurrence on its permeability, samples were taken at the following sites: Tenteksky, with sampling depths of 450, 470, 500 m, Saransky, sampled from 600, 620, 635 m, Promyshlenny, from 460, 480, 500 m, Sherubainurinsky, 420, 435, 440 m, and Taldykuduksky, 460, 475, 500 m.

All laboratory studies (analyses and tests) were conducted at the Abylkas Saginov Karaganda Technical University (Karaganda, Kazakhstan).

3. Laboratory Research

The whole set of sample processing involved determination of gas composition, technical analysis of samples (Ad, W, Vdaf), calculation of methane content (CH4+heavy hydrocarbons) was carried out in laboratory conditions. A total of 107 representative samples were selected from 59 seam intersections. The largest number of samples came from the thickest seams: K18, K12, K10, and D6. The results of the laboratory investigations are shown in Table 2 and demonstrate the amount of desorbed methane in the selected samples. The highest values were found in the samples from the Dolinskaya formation that is connected with the stage of coal maturation (coal rank).

Table 2

Results of methane desorption from coal seams

Sample number | Seam | Initial pressure, MPa | Volume of desorbed methane, cm³/g | Temperature, °C | Time to peak desorption, hours |

K18-1 | K18 | 1.98 | 5.22 | 18.8 | 8.0 |

K18-2 | K18 | 1.46 | 7.62 | 22.7 | 9.2 |

K18-3 | K18 | 1.94 | 5.99 | 18.1 | 14.1 |

K18-4 | K18 | 1.61 | 6.79 | 21.1 | 6.5 |

K18-5 | K18 | 2.3 | 8.29 | 20.2 | 8.9 |

K12-1 | K12 | 1.4 | 7.05 | 18.8 | 14.8 |

K12-2 | K12 | 2.48 | 6.04 | 22.5 | 13.1 |

K12-3 | K12 | 2.02 | 6.91 | 20.2 | 12.2 |

K12-4 | K12 | 2.03 | 7.65 | 20.2 | 12.2 |

K12-5 | K12 | 1.53 | 7.09 | 20.8 | 11.7 |

K10-1 | K10 | 1.38 | 6.01 | 21.1 | 12.4 |

K10-2 | K10 | 1.66 | 5.52 | 20.0 | 6.0 |

K10-3 | K10 | 2.42 | 5.72 | 18.5 | 13.6 |

K10-4 | K10 | 2.34 | 8.37 | 22.6 | 9.5 |

K10-5 | K10 | 1.98 | 5.82 | 22.8 | 11.7 |

D6-1 | D6 | 1.75 | 5.08 | 21.9 | 12.7 |

D6-2 | D6 | 2.1 | 5.05 | 20.5 | 10.4 |

D6-3 | D6 | 2.04 | 7.65 | 20.9 | 14.6 |

D6-4 | D6 | 2.18 | 8.45 | 21.6 | 10.6 |

D6-5 | D6 | 1.36 | 6.18 | 22.8 | 11.8 |

A detailed description of these methods is not provided in the paper, as they are widely recognized in professional circles. Instead, emphasis is placed on refining the parameters of the Langmuir equation and adapting the methods to the conditions of the Karaganda basin.

Analysis of methods for identifying promising sites in countries around the world which extract methane

Many different approaches are proposed for identifying promising sites for methane extraction, one of which is computer modeling of a deposit. For these purposes, a deposit is divided into small areas, which then are compared with each other in a number of characteristics. This method is discussed in more detail in [10]. Its essence lies in a multi-stage analysis of the prospectivity of territories for coal seam methane extraction. The method includes the following main stages: division of a deposit into sites – geological and structural zoning of the territory is carried out, with identifying blocks with different geological and geophysical characteristics; determination of site parameters – assessment of gas content, permeability, coal seam thickness, depth, degree of fracturing, and other criteria affecting methane recoverability; selection of sites suitable for commercial development based on a combination of technical, technological, and economic parameters; ranking by level of prospectivity – sites are classified according to drilling priority based on an integral prospectivity index; making drilling decisions – based on the assessments obtained, operating procedure for drilling methane producing wells is formed and their key characteristics (depth, design, flow rate, etc.) are determined; assessment of integral methane recoverability – potential methane extraction volumes are calculated by mine field; analysis of financial viability – the economic effects of planned coal seam methane production are assessed, taking into account capital and operating costs. This approach allows for well-founded planning of degassing measures, increased performance of commercial methane production, and minimization of geological and economic risks.

In [11], a method for identifying promising sites ("gas domes") is proposed, which includes geodynamic zoning of the territory under consideration, conducting geophysical surveys to verify the results of geodynamic studies, drilling of exploratory wells to confirm the presence of gas domes, their delineation using wells data, and drilling of directional inclined-horizontal wells for early degassing of the mine field with the feasibility of using the methane obtained. The use of this method allows confirming the boundaries of gas domes identified on the surface during geodynamic zoning and determining the preliminary volume of methane gas resources.

Another method is to evaluate sites based on key factors that affect methane production. For example, they take into account the depth of occurrence, faulting, permeability, and methane content of coal seams. Each assessed site is assigned a score from 10 to -10, where 10 is the best indicator, while negative values are assigned to indicators that have a negative impact. Gas saturation and critical gas desorption pressure indicators are also used to determine the prospects for methane extraction from coal seams. This method is described in paper [12].

In foreign countries, such as the United States, a comprehensive method of identifying "sweet spots" is used to determine promising methane extraction sites: geological, technological, geophysical, and petrophysical studies to determine the permeability and porosity, physical and mechanical properties, elemental and material composition of coal and coal-bearing rocks; coal seam assessment, which is carried out based on the analysis of well log survey data, core and slurry studies, geological and technological studies, hydrodynamic studies, and seismic surveys, during which petrophysical relationships are established, fractured zones and regional faults are identified, and the data is linked to coal horizons; core samples are taken to determine the amount of gas and the permeability of coal in a given site6 [1]. To increase the performance of methane extraction from coal seams (up to 80%), a process was developed and implemented based on the application of pneumatic and hydrodynamic actions on a coal mass, which contribute to the intensification of desorption and increased gas recovery [13]. Similar approaches have been successfully applied in Australia7 [1] and China [14], where they have proven their effectiveness for low-permeability and complex coal seams.

Studies [7, 10] present various methods used in Russia to determine the potential of sites for methane extraction at different stages of coal-gas deposit development. For example, at the regional stage, geological data is obtained after coal exploration, and, based on this data, the most promising sites for exploration for gas are selected. During the exploration and appraisal stage, structural wells are drilled and seismic surveys are conducted to clarify the structural and tectonic structure of a deposit, study the geological sequence of a coal-bearing formation, and investigate the permeability and porosity of coal seams. The information presented is a key to identifying the most productive coal seam groups and making informed decisions about positioning of exploration and appraisal wells. In addition, a retrospective method of predicting methane resources based on the analysis of historical data on coal mining and methane release is used to assess the methane content potential of mine fields. The method takes into account: actual coal production volumes and methane release both for mines as a whole and for individual mining sites; the effectiveness of previously used degassing and methane extraction techniques; changes in gas abundance under different mining, geological, and geotechnical conditions. This approach makes it possible to improve the reliability of methane resource forecasts and identify patterns in the spatial distribution of methane-bearing coal seams8 [4].

6 Coal bed methane: Prospects for the development of unconventional hydrocarbons in the CIS. 2011. URL: https://gaap.ru/articles/Metan-ugolnyh-plastov/

7 Ibid.

8 Shevtsov A. G. Geotechnical justification for the use of multilateral horizontal wells in coal seam methane extraction. [Abstract dis. … Cand. Eng. Sci.]. Kemerovo; 2021. 123 p.

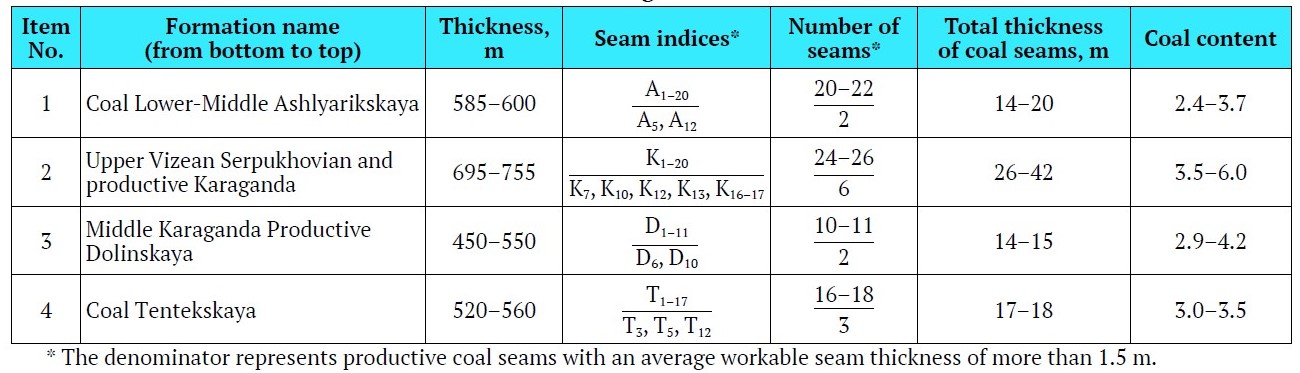

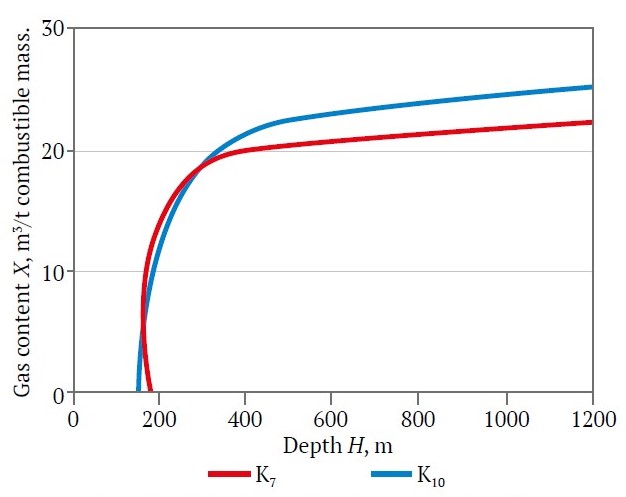

Analysis of coal seams in the Karaganda coal basin

The Karaganda Basin is one of the largest in Kazakhstan and is divided into seven formations with balance reserves estimated at 9.5 billion tons, including 0.6 billion tons of brown coal and 8.9 billion tons of hard coal, of which 5.5 billion tons is coking coal. The Karaganda basin comprises about 80 coal seams with an average total thickness of 110 m, but only 65 seams have a workable thickness (more than 0.6 m). The total thickness of all coal seams averages 110 m. The coal content of individual formations is shown in Table 3.

Table 3

Characteristics of the Karaganda Coal Basin formations

*The denominator represents productive coal seams with an average workable seam thickness of more than 1.5 m.

It should be noted that gas content and methane content are also important factors determining the quality of coal. The average gas content of coals in the Karaganda basin is 20–25 m3/t of combustible mass, which depends on the material composition, coal rank, structural position, and tectonic structure. The main gas in the basin's subsoil is methane. Research has shown that as the coal rank (degree of maturation) increases, gas content rises from 15–20 m³/t of combustible mass for gas and fat coals to 20–27 m³/t of combustible mass for coking and lean sintering coals. Table 4 shows the characteristics of coal gas content ranges by site of the main formations in the Karaganda basin. The highest values were recorded in the Karadzharo-Shakhansky and Tenteksky sites that was connected with the depth of the seams occurrence and high vitrinite content.

Table 4

Gas content of the Karaganda basin coals

Karaganda coal basin site, deposit, basin | Depth of flash gas zone H0 | Gas content at a depth of 400 m, m3/t of combustible mass | Coal rank | Amount of fusible components (FC), % | |

Raw coal | Concentrate with an actual density of less than 1.4 g/cm3 | ||||

Ashlyarikskaya formation | |||||

Promyshlenny | 90 | 20 | K1 | 35–54 | 50–60 |

Karaganda formation | |||||

Promyshlenny (east) | 140 | 13 | Zh1 | 41–66 | 50–72 |

Saransky | 120 | 20 | K1, K2 | 35–60 | 45–60 |

Tsentralny | 100 | 23 | K2 | 38–79 | 50–87 |

Yuzhny | 125 | 24 | K3, OS | 40–80 | 50–88 |

Manzhinsky | 125 | 22 | K1, K2 | 45–80 | 55–86 |

Dolinskaya formation | |||||

Dubovsky | – | 16 | G3, Zh1 | 61–70 | 69–78 |

Dolinsky | 180 | 20 | Zh3, K1 | 57–80 | 7–88 |

Karadzharo-Shakhansky | 200 | 19 | Zh2 | 55–80 | 66–87 |

Tenteksky (southeast) | 180 | 24 | Zh3, K1 | 57–80 | 65–85 |

Tenteksky (northwest) | 300 | 17 | G3, Zh1 | 57–81 | 70–85 |

Samarskoye deposit | 150 | 10 | G2 | 65–70 | 80–85 |

Zav’yalovskoye deposit | 200 | 16 | G | 60–75 | 75–85 |

Tentekskaya formation | |||||

Tenteksky (northwest) | 350 | 15 | G3 | 41–71 | 65–84 |

Tenteksky (east) | 170 | 21 | G | 40–70 | 64–84 |

According to preliminary estimates, 24.3 trillion m3 of methane formed in the Karaganda basin to a depth of 1,800 m, part of which (about 8%) remained in coal and dispersed matter, part (18%) migrated into the host rocks, and the bulk of the gases (more than 18 trillion m³) migrated into the atmosphere due to the absence of reliable reservoirs and clayey geological caps. Opening virtually all positive geological structures ruled out the possibility of the formation of independent large natural gas accumulations in the basin.

For example, let us consider the quality characteristics of coal from the Dolinskaya and Karaganda formations in terms of gas content and methane content.

Dolinskaya formation:

For seams D3 and D4, the depth of the flash gas zone (Ho) is 252 m. Below this depth, the gas content growth gradient is 1.5 m3/t of combustible mass per 100 m of depth. Thus, within the boundaries of the field, the gas content of seams D6, D5, and D4 will not exceed 13.6 m³/t of combustible mass. For seams D2, D1–2, and D1, the depth of the flash gas zone (Ho) is 249 m. The most intense increase in gas content occurs from the surface to a depth of 400 m, and the content reaches 11 m³/t of combustible mass. Within the range of 400–650 m, the gas content increases by 1.0–0.5 m³/t of combustible mass per every 100 m of depth, and finally the gas content stabilizes at 13.9 m³/t of combustible mass.

Karaganda formation

The coal rank (stage of maturation) increases vertically downward and, in plan, in the north-western direction, corresponding to the thickness of the Karaganda formation. The average methane content of the seams from the upper boundary of the site (700 m) to the lower boundary (1,400 m) increases by 0.5–2.3 m³/t of combustible mass and does not exceed 30 m³/t of combustible mass. The depth of the upper boundary of the methane zone ranges from 61 to 165 m. According to the study, all seams are hazardous in terms of coal burst. In the lower horizons (at depths of 700–1,400 m), compared to the upper horizons, the methane content decreases from 91 to 82% that is compensated by an increase in the percentage of heavy hydrocarbons from 1–2.8 to 9–12%, less frequently up to 17%, which are mainly represented by ethane, propane, butane, and isobutane in a ratio of 155:28:1:3. The effect of maturation is manifested in the fact that the methane content in the seams increases with depth, rising from the upper seam to the lower seam. The coal from the upper seam group (K20–K15) has the lowest methane content, while the coal from the lower subformation of the Karaganda formation (K53–K1) has the highest methane content. The changes in methane content downdip of coal seams within deep horizons are illustrated in Table 5. The highest average methane content values were recorded in the K53–K1 seams, while the lowest ones, in the K20–K15 seams. This is due to the fact that gas pressure increases with depth and the sorption capacity of coal decreases with increasing rock temperature. However, the average methane content in the Karaganda formation seams ranges from 21.6 to 25.6 m3/t of dry ash-free (daf).

Table 5

Change in methane content downdip of coal seams within the deep horizons of the Karaganda formation

Seam index | Methane content, m3/t daf, at a depth, m | ||||||||

700 | 800 | 900 | 1,000 | 1,100 | 1,200 | 1,300 | 1,400 | Average value | |

K20–K15 | 22.4 | 23.1 | 23.6 | 24.0 | 24.3 | 24.6 | – | – | 23.7 |

21.6 | 21.6 | – | – | – | – | – | – | 21.6 | |

K14–K13 | 23.0 | 23.7 | 24.2 | 24.6 | 25.0 | 25.3 | 25.5 |

| 24.5 |

23.0 | 23.8 | 24.3 | – | – | – | – | – | 23.7 | |

K12 | 21.4 | 21.8 | – | – | – | – | – | – | 23.7 |

23.5 | 24.2 | 25.3 | 25.7 | 26.0 | 26.3 | – | – | 25.1 | |

24.0 | 24.4 | 24.7 | 24.9 |

|

| – | – | 24.5 | |

K11–K9 | 23.0 | 23.9 | 24.7 | 25.2 | 25.6 | 26.0 | 26.4 | 26.7 | 25.2 |

22.8 | 23.2 | 23.4 | 23.7 | 23.9 | – | – | – | 23.4 | |

K7–8 | 21.2 | – | – | – | – | – | – | – | – |

23.1 | 23.8 | 24.3 | 24.7 | 25.1 | 25.4 | 25.6 | 25.8 | 24.8 | |

22.2 | 23.5 | 24.6 | 25.5 | 26.5 | 26.9 | – | – | 24.9 | |

K53–K1 | 21.6 | – | – | – | – | – | – | – | – |

25.6 | 25.8 | 26.0 | 26.1 | 26.2 | 26.3 | 26.4 | – | 25.6 | |

23.8 | 24.4 | 24.9 | 25.3 | 25.6 | 25.9 | 26.1 | – | 25.1 | |

Gas сontent of host rocks

The factors determining the gas content of the deep horizon seams are depth, coal rank, composition, and gas pressure. Among them, the most effective is the depth of seam occurrence, due to which methane content in the depth range of 700–1,400 m increases by 0.8–3.4 m3/t daf. Coals at this depth belong to the K grade and, to a lesser extent, to the OS grade. Due to the fact that coal seams within the site occur deeper than 700 m, factors such as overburden, seam dip angles, and seam disturbance lose their significance for methane redistribution, as at these depths it is in an equilibrated, almost stable state, which can be disturbed by mining operations or degassing of coal seams and rocks.

In the coal-bearing strata, the gas content in an occluded state is extremely negligible and depends mainly on the presence of organic matter in it. The overwhelming volume of free gas fills the pore space in sandstones and siltstones. Therefore, the quantitative content of gas in rocks is directly dependent on their porosity and gas pressure. Table 6 shows the gas content of the host rocks at depths ranging from 700 to 1400 m. The highest values were recorded for argillite at a depth of 800–900 m and for sandstone at a depth of 900–1000 m.

Table 6

Gas content of host rocks

Rock | Gas content, m3/t, at depth interval, m | ||||||

700–800 | 800–900 | 900–1,000 | 1,000–1,100 | 1,100–1,200 | 1,200–1,400 | Average value | |

Argillites | 2.8 | 4.2 | 1.2 | 2.7 | – | – | 1.2–4.2 |

Sandstones | 0.03 | 0.03 | 0.9 | 0.08 | 0.11 | 0.1 | 0.03–0.11 |

The gas content of the host rocks was determined using samples collected by core gas samplers. The results of the sample analysis showed that the rocks have been degassed to a depth of 250–300 m. Their methane content to a depth of 800 m does not exceed 4 m3/t. The average gas content of the host rocks is 1.3 m3/t. But even if we assume it to be equal to 1 m3/t, the methane amount in the sandstones occurring below 300 m will be about 7.4 billion m3.

In the Karaganda Basin, the dimensions of flash gas zones (FGZ), reaching 400 m from the earth surface, are extremely incontinuous. The average methane content of coal in the basin is 12–15 m3/t, and that of the host rocks is less than 1 m3/t, with maximum methane contents of 25–40 and 4 m3/t, respectively.

When examining issues related to methane extraction, it can be concluded that the Karaganda coal basin is essentially a coal seam methane deposit9 [15–17], with 1 to 4 trillion m3 of gas accumulated at a depth to 1,800 m. It should be emphasized that approximately 500 million m3 of gas is extracted annually through degassing, with only 15% of this volume being used for industrial and production needs, while the rest contributes to emissions into the environment. The lack of a unified and reliable methodology for estimation of methane resources makes it impossible to accurately determine their amount due to different exploration maturity of deposits and different approaches to the estimation. Meanwhile, the recognition of this gas as an alternative energy source is confirmed by the level of capital investment in coal seam methane extraction projects around the world10 [5, 18].

9 Coal Washing & Power generation from washery rejects. Coal bed methane 2nd Indo-US Coal Working Group meeting. Washington; 2005.

Pashin J. C. Geologic heterogeneity and coalbed methane production – experience from the Black Warrior Basin. In: Selected Presentations on Coalbed Gas in the Eastern United States. U.S. Geological Survey Open-File Report 2004–1273. Pp. 61–92.

10 Turabaeva Zh. Kazakhstan's methane prospects. Mining and Metallurgical Industry. Almaty; 2019. P. 43. (In Russ.) URL: https://metalmininginfo.kz/archives/6134

The influence of geological and technical factors on the prospectivity of sites

The volume of methane resources is determined by the following factors: the total and commercial coal content of a deposit in a basin, gas pressure values, natural methane content, formation temperature depending on depth (from the surface and from the upper boundary of methane gases), coal rank, and, to a lesser extent, the petrographic composition of coal [19].

In the main seams of the Karaganda formation at a depth of 400 m, the content of gas is 22–25 m3/t. Its content increases to 25–27 m3/t in the Sherubainurinsky and Tenteksky sites. The flash gas zone in these sites is located at depths of 120–175 and 130–160 m, respectively. At the same time, the depth of coal seams occurrence has a significant effect on their gas content. Most researchers have concluded that gas content increases with depth according to a hyperbolic law and can be described using the Langmuir equation:

X = c(H − H0)/(1 + b(H − H0)), (1)

where H is the depth of a seam, m; Н0 is the depth of a methane zone surface, m; c and b are constants for a given seam.

Gas pressure in coal seams was studied by the Institute of Geophysics of the Academy of Sciences of the Kazakh SSR and the former VostNII [18]. The results of these studies showed that methane pressure increases with depth according to the relationship [19], which for depth interval 0 to 800 m can be approximated by a straight line of the form

P = 0.1Hc, kgf/cm2, (2)

where Hc is the depth of occurrence from a conditional level, m.

For various seams of the Karaganda coal basin, the value of Hy varies between 200 and 800 m. Study [19] shows that gas pressure increases gradually with increasing depth of a seam. This is because a number of factors influences the distribution of gas in a coal-bearing formation, including gas pressure and gas permeability.

The average geothermal gradient in the Karaganda coal basin is 1.6 °C per 100 m. This is almost half the average value of this indicator for the upper parts of the Earth's crust, but close to the value of this indicator for the world's carbon basins. In such cases, the porosity of coal is usually around 3–5%.

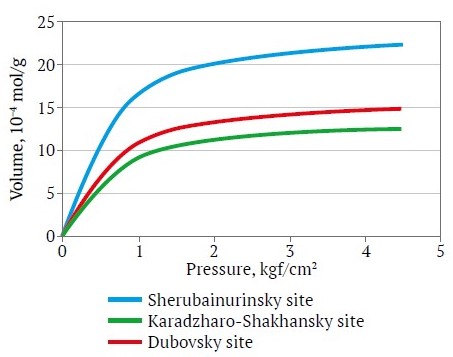

The ability of coal seams to retain significant volumes of gas even at reduced reservoir pressure is due to their high sorption capacity. This effect is caused by weak intermolecular forces, mainly Van der Waals forces, which ensure the adsorption of methane molecules on the inner surface of the pore space of coal. Significant volumes of gas can be concentrated in coal due to its large area of internal microporosity surface [6, 20, 21]. Through laboratory studies with controlling thermobaric conditions, coal sorption capacity isotherms were constructed. The characteristic dependencies between pressure and sorption capacity of coal obtained as a result of the research are presented in Fig. 3.

Fig. 3. Methane Sorption Isotherms at t = 20 oC:

1 – Sherubainurinsky site; 2 – Karadzharo-Shakhansky site; 3 – Dubovsky site

The data analysis shows that the Sherubainurinsky site may contain the largest amount of gas, since the coal sorption capacity increases more intensively with increasing pressure, while the Karadzharo-Shakhansky site may contain the least amount.

Based on the results of studying the sorbed methane content of coal seams in the basin, the dependencies of coal gas sorption on gas pressure, temperature, petrographic composition of coal, and moisture content have been determined. The research yielded data indicating that the coals of the Karaganda basin are characterized by insignificant variability of maturation. The established level of carbonification corresponds to stages III–IV of maturation according to accepted classifications [22]. The analysis of the petrographic composition of coals from the Karaganda basin showed that microcomponents of the vitrinite Vt and fusinite F groups dominate in the basin's coals, and their quantitative contents correlate quite closely (r = 0.84). The relationship between the main groups of microcomponents in the petrographic composition is described by the following equation:

F = 76.7–0.849 Vt, %, (3)

where F and Vt are fusinite and vitrinite contents, respectively.

Therefore, the petrographic composition is assessed based on one of the main indicator, the fusinite F content, which is calculated based on the organic mass of coal, since the sorption capacity of the mineral part of coal is low.

All isotherms were processed using the Langmuir equation:

X = abP/(1 + bP‘), cm³/t combustible mass, (4)

where a and b are coefficients of the Langmuir equation, in cm3/t and cm2/kg, respectively; P is pressure, kgf/cm2.

The determination of a and b coefficients involved the use of the least squares method for the normalized equation:

P/Xp = 1/(ab) + 1/a · P. (5)

Next, a criterion method was used to search for specific dependencies for the values of the Langmuir coefficients a and b on temperature and fusinite content, which have the following form:

According to Prof. M. M. Protodyakonov's method, the formula for multifactorial dependence is the product of partial empirical dependencies divided by the general average of the entire data set, raised to a power one less than the number of primary factors. Thus, a = f(t, F) will look as follows:

similarly, b = f(t, F)

where and are the corresponding general means.

When studying the material composition, it was found that the gas content of host rocks, such as argillites, only in individual cases exceeds 5 m3/t, while in the vast majority of cases it is less than 2 m3/t. It is characteristic that the stabilization of gas content coincides with the stabilization of their porosity. For instance, in the weathering zone of the Karaganda formation argillites, which extends to a depth of 300 m, the gas content of these rocks is minimal.

The gas content of the siltstones and sandstones, determined from single samples, is 4–5 m3/t. These rocks are characterized by good gas recovery and require almost no thermal vacuum degassing. The argillites, on the other hand, are freed from gas only when heated to a temperature of 70–80° and subjected to deep vacuuming. The latter circumstance allows the inflow of methane from the host rocks into wells to be reduced to a negligible amount.

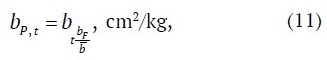

A study of gas (methane) content in the mines of the Promyshlenny and Saransky sites11 [23] showed that as the maturation of coal increases in the western direction (i.e., toward the Sherubainurinsky coal-bearing district), the gas content also increases [24]. An increase in gas abundance with depth has also been established, as clearly demonstrated by the graph in Fig. 4. The total amount of methane formed in the process of coal maturation has approximately the following values by coal rank12: G – 212 m3/t; Z – 229 m3/t; K – 270 m3/t; OS – 300 m3/t; T – 330 m3/t, which does not contradict the data of historical research. Thus, the potential gas resources in the coal-bearing strata of the Sherubainurinsky Syncline are estimated to be significant. At the same time, the current level of methane content is determined primarily not so much by methane generation as by the geological and structural conditions, and porosity and permeability, governing its migration and accumulation. For K7 seam, gas content increases gradually with depth. In the early stages, gas recovery growth is slow due to significant fractures formed as a result of rock mass deformation (block fragmentation). For K10 seam, gas content also increases with depth, but more sharply. This is because the gas content of coal seams depends on the depth of occurrence, the coal rank, and the gas pressure.

Fig. 4. Gas content of coal seams K7 and K10 as a function of depth

Data on the coal and gas content of the Karaganda formation within mining fields 35/36 and 37/38 are provided in geological report13, where they are classified as fields not covered by gas sampling. Their gas resources were estimated by analogy with the Stepnaya mine field and summarized in comparative Table 7, which shows that despite the identical estimated gas content of these the Karaganda formation fields based on balance reserves, the total methane resources of mine field 35/36 are significantly less and amounts to less than 0.75 billion ethane3, as compared to mine field 37/38 with more than 1 billion m3.

Table 7

Gas content of coal seams and carbonaceous rocks of the Karaganda formation within mine fields 35/36 and 37/38 (According to the 1989 Geological Report)

Indicator | Mine field 35/36 | Mine field 37/38 | |

550 | 570 | ||

Average gas content, m³/t | 14.53 | 14.69 | |

Depth of level 10 m³/t, m | 318 | 318 | |

For balance reserves | total thickness, m | 3.7 | 3.7 |

Reserve category | А+В+С | А+В+С | |

Coal reserves, kt | 28,427 | 39,508 | |

Estimated gas content, m3/t | 12.27 | 12.35 | |

Gas resource category | Р1 | Р1 | |

Coal reserves, kt | 348,799 | 487,924 | |

For off-balance reserves | Coal reserves, kt | 10,423 | 13,886 |

Gas resource category | Р2 | Р2 | |

Gas resources, thousand m3 | 127,890 | 171,492 | |

For non-workable coal seams | Total thickness, m | 2.24 | 2.24 |

Gas resource category | Р3 | Р3 | |

Gas resources, thousand m3 | 211,165 | 295,392 | |

For carbonaceous rocks | Total thickness, m | 1.4 | 1.4 |

Gas resource category | Р3 | Р3 | |

Gas resources, thousand m3 | 65,989 | 92,310 | |

Total coal reserves, kt | 38,850 | 53,394 | |

Total methane resources, thousand m3 | 753,843 | 1,047,118 | |

According to available data for the Northern site14, located southeast of the designed site, the seams have been degassed to a depth of 140–150 m that is explained by their rather steep dipping. It has been established that intensive growth in gas content occurs in the first 100 m from the surface of the methane zone, i.e., to a depth of 250 m from the surface. Within this short interval, which is characteristic of steeply dipping strata, the gas content of the seams increases from 2 to 20 m³/t of combustible mass. The gradient of its growth does not exceed 1m3/t combustible mass per 100 m of depth, and at a depth of 1,000 m, the gas content reaches 24 m3/t combustible mass. The described trend in gas content is characteristic of all seams starting from K10 and downward.

The total methane resources in the Karaganda formation in mine fields 35/36 and 37/38 amount to 1.75 billion m3. The gas content of the Ashlyarikskaya formation coal seams at a depth of 135–140 m is 15–20m3/t daf. Downward this depth, the Kirovskaya mine is classified as super-category in terms of gas, and from a depth of 180–200 m downward, A5 and A7 seams undergo preliminary degassing. There were no sudden coal and gas outbursts. Within the projected site, the gas content of the Ashlyarikskaya formation coals, like those of the Karaganda formation, has not been studied.

The determination of a site's prospectivity (potential) is based on the development of geological assessment criteria, comprising analyzing the depth of occurrence, faulting (disturbance), permeability, and methane content of coal seams to identify the most gas-saturated sites, which can be considered promising for methane extraction from coal seams [10]. The criteria-based rating of a site's prospectivity consisted in assessing coal seams based on 10 key factors and took into account the influence of moisture content, volatile-matter yield, methane desorption, and seam permeability at various depths. Fig. 5 shows the coal content of the formations, taking into account the total and workable number of seams, as well as their total thickness.

Fig. 5. Coal content of coal seams in the Karaganda Basin

The paper [10] presents the results of determining the permeability of the most gas-bearing formations in the studied sites depending on depth. With a small difference in depth, a decrease in formation permeability is observed with increasing depth. The results of processing the obtained permeability data as a function of a depth of occurrence are presented in Fig. 7.

Fig. 6. The effect of coal seam depth on its permeability

*Source: Gurevich Yu. S. Extraction of commercial methane during underground coal mining and process solutions for its use. [Doctoral thesis in Eng. Sci.] Moscow: MGI; 1990. 531 p. (In Russ.)

The data analysis (Fig. 6) shows a stable negative correlation between depth and permeability of seams (r ≈ –0.85), which is explained by increased rock pressure and compaction of rock. This, in turn, affects the permeability and desorption capacity of coal. A correlation between gas content and coal rank has also been identified: as the fusinite content increases, methane content increases too that is confirmed by the regression equation (see formula (4)). The data indicate the priority role of petrographic composition in the formation of methane resources.

The methodology for assessing the studied sites is as follows: for a comprehensive comparative characterization of gas-bearing coal sites, a factor-point assessment method was used, in which points were assigned to each site according to a number of key parameters reflecting its prospectivity (potential) in terms of methane content and degassing. Each parameter is rated on a scale from 10 to –10 points, where 10 corresponds to the most favorable value and –10 to the least favorable one. A negative value is assigned to an indicator that has an adverse impact. The parameters evaluated comprised permeability (gas permeability), which characterized the ability of a coal mass to allow gas to pass through. The higher the permeability is, the higher the degassing efficiency. The parameters also involved desorption capacity, reflecting the intensity of adsorbed methane release from coal; resource density, which estimates the potential volume of gas contained in the coal mass per unit area or volume; methane content, showing the actual methane content in a coal mass, determined on the basis of direct measurements; volatile-matter yield, reflecting the content of organic components in coal and indirectly indicating the potential for methane formation; moisture, characterizing the moisture content in coal and rock. Since increased moisture hinders gas desorption, this factor is considered negative and its value is taken into account in the calculations with a minus sign.

The final score (summary indicator) for each site is determined by adding up all the points assigned, taking into account the sign for moisture content.

Interpretation of results: the higher the final value, the more promising a site is in terms of potential gas recovery, degassing feasibility, and conditions for effective methane extraction. For example, the Sherubainurinsky site has the highest integral score (38 points), making it a priority site for degassing measures and pilot-plant operations.

The criterion rating for each site, taking into account fundamental geological and technical factors based on the results of the studies conducted (Table 8), showed that the Sherubainurinsky site is characterized by good resource density, methane content, and volatile-matter yield, but lags behind the other sites in terms of desorption and moisture content. The most promising sites proved to be Sherubainurinsky, Saransky, and Taldykuduksky, while the Tenteksky site demonstrated the lowest indicators.

Table 8

Factor-point assessment of the sites under investigation

Sites under investigation | Points assigned for various factors | Summary score indicators | |||||

Permeability | Desorption | Resource density | Methane content | Volatile-matter yield | Moisture | ||

Sherubainurinsky | 9 | 7.5 | 10 | 9 | 9 | −6.5 | 38 |

Saransky | 8 | 5 | 10 | 9 | 9 | −7 | 34 |

Taldykuduksky | 5 | 7 | 10 | 10 | 10 | −10 | 32 |

Promyshlenny | 5 | 6 | 10 | 9.5 | 9.4 | −8 | 31.9 |

Tenteksky | 5 | 7 | 6 | 10 | 10 | −9 | 29 |

Unlike approaches available in the literature, which are based on a limited set of geological parameters (depth, gas content, permeability), the methodology developed in this study uses an expanded list of factors, 10 key characteristics, including petrographic and thermodynamic characteristics of coals. This allows for a more complete and objective assessment of the prospectivity of sites.

Thus, a distinctive feature of this study is an integration of the methods of desorption analysis, petrographic evaluation, and parametric permeability, combined into a unified evaluation algorithm suitable for implementation in degassing design practice.

An analysis of existing solutions [8, 9] shows that most of them do not take into account:

- sorption and structural properties of coals (Langmuir isotherms);

- the influence of microcomponent composition (fusinite, vitrinite);

- desorption characteristics and rock moisture content.

The advantage of the proposed approach is the multifactorial nature of the assessment, its universal applicability, high practical applicability, and increased forecast accuracy due to the refinement of Langmuir equations and the introduction of the correlations with fusinite content and temperature.

Thus, the scientific novelty of the research is expressed in the development and experimental confirmation of an integrated methodology for assessing coal seam sites, which makes it possible to replace expert, poorly formalized approaches with a quantitative, scientifically sound methodological system with verifiable parameters.

11 Natura V. G., Sirotsky R. G., Ozhogina T. V. Russian Federation Patent No. 2601205 Method for determining gas content of coal seams. Appl. on 07.08.2015. Publ. on 27.10.2016.

12 Akhmatnurov D. R. Research into methods for intensifying gas recovery from unloaded coal seams. [PhD dis.]. Karaganda: Karaganda State Technical University; 2018. pp. 142–149. URL: https://www.kstu.kz/o-zashhite-doktorskoj-dissertatsii-ahmatnurova-denisa-ramilevicha/?lang=ru (Date accessed: 08.09.2025).

13 Yermekov, M. A. Gas Content of coal-bearing deposits and gas abundance of mines in the Karaganda Basin. [Abstract dis. … Cand. Geol. and Min. Sci.]. Alma-Ata: Kazakh Polytechnic Institute; 1963. 63 p.

14 Akhmatnurov D. R. Research into methods for intensifying gas recovery from unloaded coal seams [PhD dis.] Karaganda: Karaganda State Technical University; 2018. Pp. 142–149. – URL: https://www.kstu.kz/o-zashhite-doktorskoj-dissertatsii-ahmatnurova-denisa-ramilevicha/?lang=ru (Accessed date: 08.09.2025).

Conclusions

An analysis of the current state and global experience in the field of coal seam methane extraction has shown that some countries are quite successfully applying various processes for extracting methane from coal seams.

The Karaganda coal basin is conditionally divided into five sites based on the potential for methane gas production. Research was conducted covering the most gas-bearing seams at each of these sites. It has been established that the gas content of coal in the Karaganda basin increases regularly with depth along the ascending branch of an S-shaped curve, with methane content reaching 25–27 m³/t at depths of over 600 m. As a result of the research, first- and second-order zones have been identified for assessing the prospects of methane extraction from coal seams. The main parameters for classifying these zones are: depth of occurrence, permeability, and desorption characteristics. Gas permeability of up to 10–15 mD can be recorded at a depth of 250–300 m.

Based on an analysis of the sorption capacity of coal seams in the Karaganda basin with respect to methane, parameters were established for models of correlation between coal sorption and factors such as gas pressure, temperature regime, petrographic composition, and moisture content. The results obtained during the research indicate that the Karaganda basin coals are characterized by insignificant variability in the stage of maturation (coal rank). Laboratory studies have established that methane content increases from 21.6 to 26.4 m³/t with increasing seam depth. For the first time for the Karaganda basin, quantitative dependencies of the Langmuir equation coefficients on fusinite content and temperature have been obtained, allowing the parameters of sorption isotherms to be refined and the accuracy of coal gas capacity estimates to be improved.

Based on the results of pilot-plant tests and experimental research, geological and technological factors characterizing the potential of sites for methane extraction were scientifically substantiated, such as: the depth of coal seams, disturbance, permeability, and methane content. The prospectivity rating was based on an assessment of coal seams based on 10 key factors and took into account the effect of moisture content, volatile-matter yield, methane desorption, and seam permeability at different depths. The final score (summary indicator) for each site was determined by adding up all the points assigned, taking into account the sign for moisture content. Interpretation of the results showed that the higher the final value, the more promising a site is in terms of potential gas recovery, degassing feasibility, and conditions for effective methane extraction. The application of a criterion-based approach made it possible to rank sites based on a scientific approach and quantitative assessments. The most promising areas were recognized to be Sherubainurinsky (38 points), Saransky (34 points), and Taldykuduksky (32 points).

The research objective has been achieved: a system has been developed that not only allows assessing the current prospectivity of the mining allotment sites, but also predicting the performance of methane production at an early stage of planning. The results of the study are of practical importance both for the design of new coal mines and for existing mines too.

References

1. Parmuzin P. N. Foreign and domestic experience in the development of coalbed methane resources: A Monograph. Ukhta: USTU; 2017. 109 p. (In Russ.)

2. Golitsyn M. V., Golitsyn A. M., Pronina N. V. et al. Gas-coal basins of Russia and the world. Ed. by V. F. Cherepovskiy. Moscow: Lomonosov Moscow State University, Russian Academy of Natural Sciences; 2002. 249 p. (In Russ.)

3. Qin Y., Ye J. A review on development of CBM industry in China. In: AAPG Asia Pacific Region, Geoscience Technology Workshop. Opportunities and Advancements in Coal Bed Methane in the Asia Pacific. February 12–13, 2015, Brisbane, Australia. Tulsa: AAPG; 2015. p.

4. Drizhd N. A., Kamarov R. K., Akhmatnurov D. R. et al. Coal bed methane Karaganda basin in the gas balance Republic of Kazakhstan: status and prospects. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu. 2017;(1):12–20.

5. Kiryaeva T. A. Evaluation of methane resources in Kuzbass in the context of new ideas on methane occurrence in coal bed. 2012;(5):67–75. Fiziko-Texhnicheskiye Problemy Razrabbotki Poleznykh Iskopaemykh. (In Russ.)

6. Kirin B. F., Zhuravlev V. P., Ryzhikh L. I. Dust control in Mines. Moscow: Nedra; 1983. 213 p. (In Russ.)

7. Nazarova L. A., Nazarov L. A., Karchevsky A. L. Method of "canister test" data interpretation for determination of coal bed diffusion and capacity parameters based on inverse problem solution. Mining International and Analytical Bulletin. 2014;(3):56–68. (In Russ.)

8. Velesevich S. V., Shek V. M. Analysis of the prospects of coal-gas field areas for methane production (case study of the Vorkuta field). Mining Informational and Analytical Bulletin. 2005;(5):132–137. (In Russ.)

9. Koryaga M. G., Sychev I. I. A seArch technique for detection of methane accumulation and identification of potential sites for industrial methane mining in southern Kuzbass. Mining Informational and Analytical Bulletin. 2015;(3):380–385. (In Russ.)

10. Musin R. A., Asanova Zh. M., Khalikova E.R. et al. Development of technological evaluation criteria for the selection of promising coal methane production sites. Ugol’. 2024;(4):102–108. (In Russ.)

11. Gresov A. I., Obzhirov A. I., Shakirov R. B. Methane resource base of the coal basins of the Russian Far East and prospects for its industrial development. Vol. I. Coal-methane basins of Primorye, Sakhalin and Khabarovsk Krai. Vladivostok: Dalnauka; 2009. 247 p. (In Russ.)

12. Lu Ya. Methodology for geological selection of coal deposits for methane extraction from coal seams in China. In: International Scientific Conference of Students, Postgraduates and Young Scientists "Lomonosov – 2018". April 10–11, 2018, Moscow, Russia, 2018. (In Russ.)

13. Yan I., Chen H., Wang H. et al. Influence of tectonic structure on methane recovery in QD site in the Qinshui coal basin in China. Fiziko-Texhnicheskiye Problemy Razrabbotki Poleznykh Iskopaemykh. 2021;(3):85–95. (In Russ.)

14. Ruban A. D., Zaburyaev V. S. Experience in the extraction and utilization of mine methane in Russia and the Federal Republic of Germany. Mining Informational and Analytical Bulletin. 2004;(9):153–158. (In Russ.)

15. Zaburyaev V. S. Coalbed methane: resources, emission volumes, extraction and utilization. Gornyy Vestnik. 1994;(1):34–39. (In Russ.)

16. Zolotykh S. S., Arnautov V. S., Surin E. V. From the depths of Kuzbass storerooms – combustible gas methane. Gazprom Dobycha Kuznetsk. Kemerovo: Kuzbassvuzizdat; 2015. 247 p. (In Russ.)

17. Legotin F. Ya., Akhmetova A. B. The analysis of state and trends of development of the coal mining industry in the Karaganda oblast. Journal of the Ural State University of Economics. 2012;(4):50–53. (In Russ.)

18. Volpova L. S., Tokareva S. G. On the error in determining natural gas content by the core gas sampler KA-61. Izvestiya Vuzov. Geologiya i Razvedka. 1973;(5):92–94. (In Russ.)

19. Gas content of coal basins and deposits of the USSR. Vol. 2. Coal Basins and Deposits of Siberia, Kazakhstan and the Far East. Ed. by A. I. Kravtsov. Moscow: Nedra; 1979. 454 p. (In Russ.)

20. Drizhd N. A., Musin R. A., Aleksandrov A. Yu., Rabatuly M. Experience in drilling a directional well for coalbed methane production. Gornyy Zhurnal Kazakhstana. 2019;(12):19–23. (In Russ.)

21. Pashchenkov P. N. Method to determine parameters of Langmuir isotherm and gas permeability of dispersed coal particles. Mining Informational and Analytical Bulletin. 2018;(3):120–128. (In Russ.)

22. Slastunov S. V. Problems of coal methane production and promising technological solutions. Mining Informational and Analytical Bulletin. 1997;(6):25–31. (In Russ.)

23. Shubina E. A., Lukyanov V. G. Study of natural gas content for the development of coal seam methane production on an industrial scale. Vestnik KuzGTU. 2016;(1):3–12. (In Russ.)

24. Drizhd N. A., Rabatuly M., Aleksandrov A. Yu. et al. The results of the development of pilot wells in the Sherubainurinsky site of the Karaganda coal basin. Ugol’. 2020;(6):36–40. (In Russ.)

About the Authors

R. A. MussinKazakhstan

Ravil A. Mussin – Associate Professor of the Department of Mineral Deposits Development

Karaganda

Scopus ID 7005446397

N. A. Nemova

Russian Federation

Natalia A. Nemova – Senior Researcher of the Open-Pit Mining Laboratory; Associate Professor of the Department of Engineering Geodesy and Mine Surveying

Novosibirsk

Scopus ID 56995813200

D. R. Akhmatnurov

Kazakhstan

Denis R. Akhmatnurov – Head of the Laboratory

Karaganda

Scopus ID 57194187849

N. M. Zamaliyev

Kazakhstan

Nail M. Zamaliyev – Associate Professor of the Department of Mineral Deposits Development

Karaganda

E. D. Reshetnyakov

Kazakhstan

Edvard D. Reshetnyakov – Engineer of the Department of Mineral Deposits Development

Karaganda

A. V. Reznik

Russian Federation

Alexander V. Reznik – Senior Researcher of the Open-Pit Mining Laboratory

Novosibirsk

Supplementary files

Review

For citations:

Mussin R.A., Nemova N.A., Akhmatnurov D.R., Zamaliyev N.M., Reshetnyakov E.D., Reznik A.V. Justification of the prospects for developing gas-bearing sites in the Karaganda coal basin. Mining Science and Technology (Russia). 2025;10(4):321–337. https://doi.org/10.17073/2500-0632-2025-06-425