Scroll to:

RETRACTED: Directional drilling of an exploratory well in the shallow waters of the Caspian Sea

https://doi.org/10.17073/2500-0632-2024-02-217

Abstract

In the rapidly evolving energy landscape, achieving not only economic benefits but also ensuring energy stability for the region and the global energy resource market has become a key objective. This study aims to optimize the processes of directional and inclined drilling of exploratory wells in the Caspian Sea offshore area in Turkmenistan, focusing on enhancing efficiency and reducing environmental impact. Among the methods used, the analytical method, classification method, functional method, statistical method, synthesis method, and others should be noted. The study involved an analysis of directional drilling processes in exploratory wells in the Caspian Sea offshore area of Turkmenistan. Innovative technologies were developed and successfully implemented to streamline production processes with an emphasis on environmental considerations. This comprehensive approach not only improves the technical readiness of energy projects in the region but also supports adherence to high standards of environmental sustainability, which is a critical component of modern energy management. Thus, the exploration of these processes is inherently connected with the formation of a sustainable and efficient energy strategy for the Caspian region. The study’s focus centers on the need for effective analysis and refinement of directional drilling processes for exploratory wells in the Caspian Sea offshore area in Turkmenistan. Key considerations include not only the goal of enhancing hydrocarbon extraction but also maintaining a balanced focus on the environmental aspects of production. The research results confirmed the effectiveness of new methods that support increased hydrocarbon production, reduce time costs, and minimize adverse environmental impacts. This study highlights not only the importance of modern technological solutions in the energy sector but also their substantial contribution to the region's sustainable development and energy security. The practical significance of this study lies in providing innovative solutions to improve directional drilling processes for exploratory wells in the Caspian Sea offshore area of Turkmenistan.

Keywords

For citations:

Deryaev A.R. RETRACTED: Directional drilling of an exploratory well in the shallow waters of the Caspian Sea. Mining Science and Technology (Russia). 2024;9(4):341-351. https://doi.org/10.17073/2500-0632-2024-02-217

Introduction

The study of directional and inclined drilling processes for exploratory wells in the Caspian Sea offshore area of Turkmenistan is an essential component of strategic planning in the energy sector. This research gains critical importance in light of the constant changes within the energy industry and the need to ensure stable supply of energy resources. The development of innovative technologies and streamlining of drilling processes contributes to increased hydrocarbon extraction efficiency and reduced environmental impact. Understanding these processes provides economic benefits and plays a key role in ensuring the region’s energy security and stability in the global energy market amid a constantly shifting energy paradigm. This comprehensive approach enhances the technical readiness of energy projects in the region and supports compliance with high standards of environmental sustainability, which is a vital element of modern energy management. Consequently, the study of these processes is inherently linked to shaping a sustainable and effective energy strategy for the Caspian region.

In [1], the application of innovative methods in directional and inclined drilling to improve hydrocarbon extraction efficiency in the Caspian Sea offshore area is emphasized. However, this study does not address the development of integrated management systems that could ensure long-term sustainability in oil and gas operations.

The research in [2] considers the development of sustainable directional drilling methods with an emphasis on environmental aspects; however, the work does not give due attention to the environmental considerations and possible impacts of these methods on the marine environment.

Study [3] highlights the of using analytical methods to assess the impact of drilling on marine biodiversity but does not consider classification methods that could help adapt to geological changes and reduce risks.

In [4], the author points out the progressive nature of synthesis methods in directional drilling (DD), which enhances hydrocarbon extraction. However, the calculations for directional well drilling with dual completion are not presented in detail.

Study [5] emphasizes the need for classification methods for effective management of directional drilling processes but does not consider the long-term effects of synthetic approaches and their impact on the marine ecosystem.

Article [6] raises a key question about the effectiveness of statistical methods in analyzing the performance of directional drilling conducted within the analytical approach framework. The study does not delve into issues regarding the social acceptability of statistical methods and their influence on public opinion.

Materials and methods

The analytical method provided a deeper understanding of the complex interconnections and dynamics in the directional and inclined drilling processes for exploratory wells in the Caspian Sea offshore area. This method helped identify the factors affecting drilling efficiency and facilitated a systematic review of data, significantly enriching knowledge about the physical and geological parameters influencing the success of hydrocarbon extraction operations.

The statistical method was employed to identify key patterns and trends characterizing the directional drilling processes in exploratory wells in the Caspian Sea offshore area. This method allowed for the analysis of large volumes of data gathered during well operations and highlighted statistically significant parameters affecting drilling efficiency. The statistical method also enabled an assessment of the reliability and predictability of drilling results, a critical factor in decision-making within the energy industry. The statistical data obtained on overall drilling efficiency, time expenditures, and other parameters served as a fundamental basis for further refining strategies and tactics used in the drilling processes in this offshore area.

The functional method helped establish the primary functional relationships between various parameters and processes associated with directional drilling of exploratory wells in the Caspian Sea offshore area. This method revealed the influence of different variables on overall drilling efficiency, identified optimal parameter values, and determined key factors affecting the success of hydrocarbon extraction operations.

The deductive method allowed for logical conclusions regarding the directional drilling processes for exploratory wells in the Caspian Sea offshore area. By applying this method, it was possible to uncover causal relationships among various drilling aspects, define the main principles and laws underlying effective technologies. Thus, using the deductive method enriched the understanding of the principles governing and managing directional drilling processes.

The application of the synthesis method led to the development of innovative solutions and technologies aimed at streamlining the directional drilling processes for exploratory wells in the Caspian Sea offshore area. This method facilitated the systematic integration of various components and variables to create effective strategies that combined technical efficiency with environmental considerations. The synthetic method enabled the incorporation of advanced technologies while accounting for numerous variables influencing drilling processes. The innovations developed through synthesis contribute not only to increased productivity but also to reduced environmental impact on the marine ecosystem. The resulting solutions represent a comprehensive set of measures, including technical enhancements, risk management, and adherence to high standards of environmental sustainability. Consequently, the synthesis method proved to be an essential tool for creating comprehensive and innovative approaches to optimizing drilling in this offshore area.

The classification method facilitated the organization of various geological formations and conditions that affect directional drilling processes for exploratory wells in the Caspian Sea offshore area. Applying this method enabled the identification of characteristics and features of different drilling zones, significantly simplifying the adaptation of drilling strategies to diverse geological conditions. The classification method also contributed to establishing a system for determining effective drilling parameters based on specific geological characteristics. This allowed for improved precision and efficiency in drilling processes, reduced potential risks, and enhanced overall efficiency. The classification results serve as a foundation for developing more precise and adaptive strategies for directional drilling in the Caspian Sea offshore area in Turkmenistan.

Results

In recent decades, global exploration and production activity in the oil and gas sector has been steadily increasing, with countries located near resource-rich regions playing a key role in this process. Turkmenistan, strategically positioned along the shores of the Caspian Sea, is one such country. Directional drilling of exploratory wells in the waters of this unique inland sea presents complex engineering and environmental challenges but also opens up broad energy prospects for the country [7].

One of the key aspects of drilling in the Caspian Sea is the use of directional well technology. This innovative approach enables drillers to extract hydrocarbons from multiple points within an underwater field, maximizing efficiency and increasing production volumes. With its vast natural resources, Turkmenistan aims to leverage advanced technology to efficiently exploit and maximize the potential of its fields.

However, despite the opportunities associated with directional exploratory drilling in the Caspian Sea, challenges also exist. Environmental concerns are paramount, as even the most advanced technologies can pose risks to the marine ecosystem. Discharges of drilling fluids, vapor emissions, and potential accidents may have serious consequences for the environment and the health of local communities [8].

Therefore, countries conducting drilling activities in the Caspian Sea must strictly adhere to international safety and environmental standards. The development and implementation of integrated control systems, continuous environmental monitoring, and active collaboration with research institutions are essential components of sustainable development in this sector [9].

A primary objective for Turkmenistan’s oil and gas industry is to increase hydrocarbon reserves. President of Turkmenistan Serdar Berdymukhamedov underscores the importance of boosting hydrocarbon production in the oil and gas sector, considering it a vital factor for ensuring the country's stability and economic independence. At the current stage of oil industry development, with advancements in drilling technology, new drilling equipment, and chemical agents, previously unknown methods and types of well construction are now feasible [10].

Traditionally, all exploratory wells were drilled vertically, but there is now justification for altering this standard practice. Experience gained from constructing the H1 horizontal directional well at the Northern Goturdepe field in collaboration with Schlumberger demonstrates the feasibility of exploratory drilling with horizontal directional wells in the shallow waters of the Caspian Sea. Drilling wells in various directions from existing artificial islands significantly reduces field exploration costs, as noted in the study [11]. At Turkmenistan’s Goturdepe Drilling Operations Department, the first successful experience with horizontal directional drilling has been achieved. Specialists from Goturdepe and Schlumberger drilled the inclined directional well H2 at the Northern Goturdepe field, deviated from the vertical at a depth exceeding 1000 m. Drilling reached 3000 m using local resources, with the directional segment drilled with Schlumberger’s specialized equipment.

The well successfully reached the planned depth of 4850 m (measured depth). The drilling process to a depth of 3000 m conformed to the technical project and was similar to methods used in other wells in the country. The kick-off point for directional drilling was set at 3000 m to achieve a zenith angle with an azimuth of 270°. The planned parameters included a zenith angle of 45°, a maximum build rate of 3.5° per 30 m, and a well deviation of 1046.58 m.

Before beginning the directional section at 3000 m, the previous water-based mud was replaced with a hydrocarbon-based mud system called Versadrill. This hydrocarbon-based formulation, developed with specialized chemical additives, contains up to 80% hydrocarbons and 20% water. The primary advantage of such muds is their high resistance to water, which results in the formation of thin and flexible mud cakes [12]. This also preserves the natural reservoir properties of the productive section, significantly reducing clay dispersion in the mud, along with other beneficial characteristics.

The use of hydrocarbon-based muds can present challenges for well cementing with cement slurries [13]. This issue arises when cement mixes with hydrocarbon-based muds, leading to coagulation, which increases the mixture’s fluidity and compaction. To prevent such issues, the Nebitgazylmytaslama Institute developed a special hydrocarbon-based spacer fluid successfully used in drilling the H2 well at Northern Goturdepe.

During the drilling of this well, systematic geological and technical testing was conducted using the new GTL Station, "Geotest-5." The "Geotest-5" device automatically collects, processes, and visualizes geological, geochemical, and technical data related to the drilling process [14]. This tool monitors drilling parameters, assesses overall drilling conditions, identifies reservoir sections, and determines their saturation levels, helping to prevent potential complications and accidents.

The station comprises three main modules: technological, gas logging, and geological [15]. The technological module manages the drilling process in real time, ensuring efficient and accurate control over drilling operations. The gas logging module records overall gas content and analyzes the gas mixture composition, playing a critical role in assessing the safety and efficiency of the process. The geological module conducts real-time analysis of core samples, drill cuttings, mud, and formation fluids, providing valuable information to assess geological characteristics and well material composition [16].

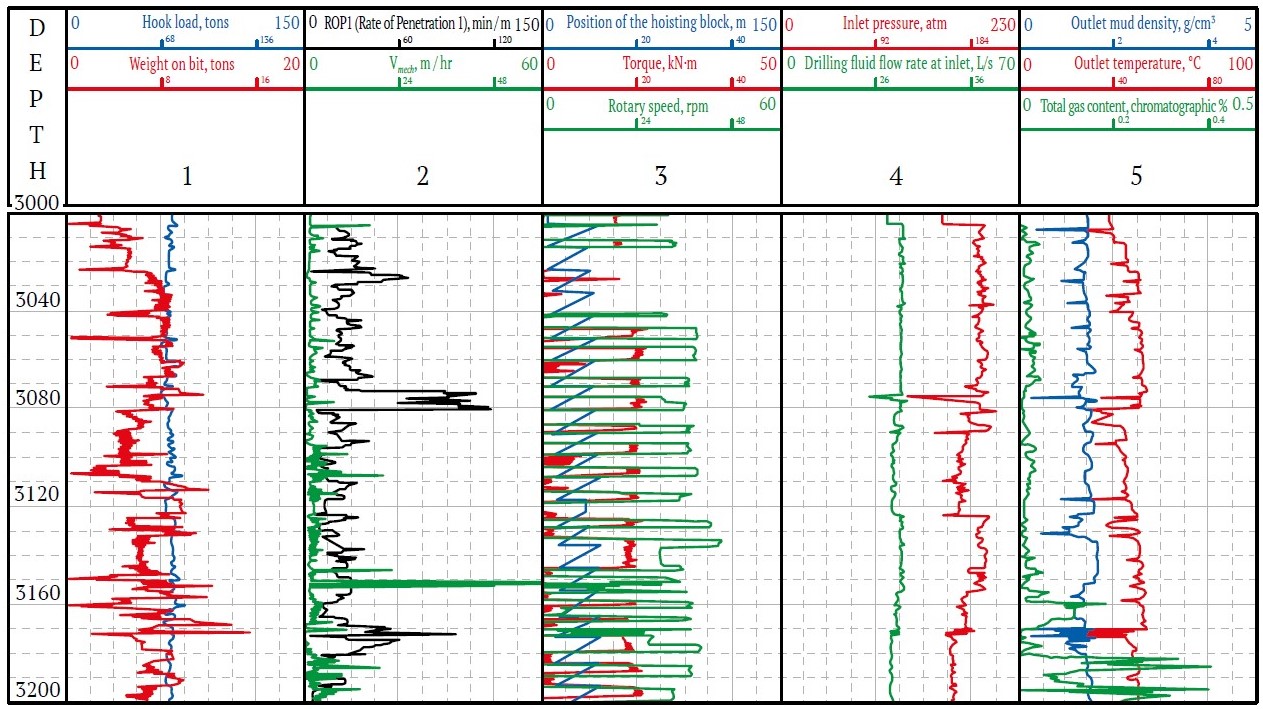

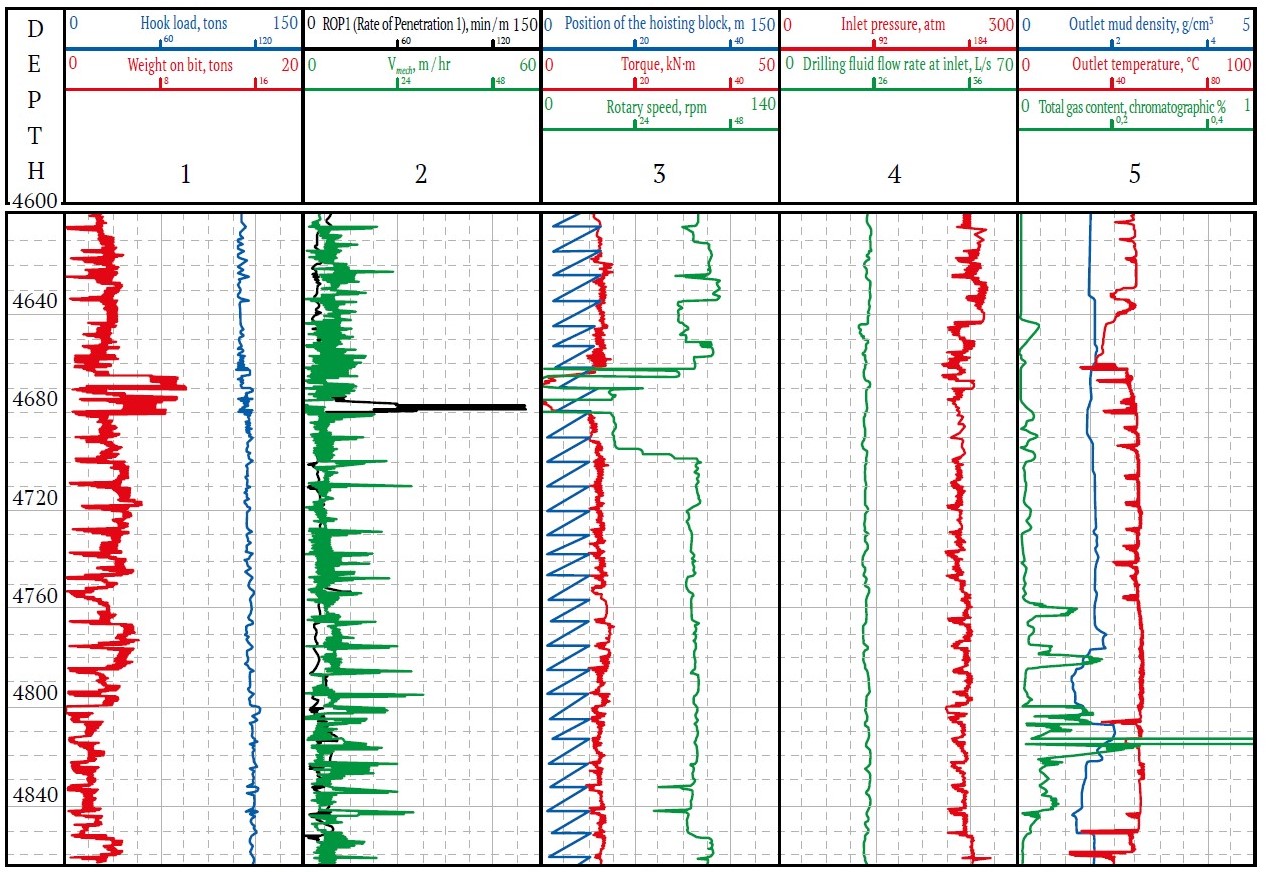

Fig. 1 shows a segment of a chart reflecting the technological parameters during the curvature build-up phase in the drilling process, while Fig. 2 presents a fragment of the straight interval of the inclined section of the well.

Fig. 1. Well deepening parameters during curvature build-up [compiled by the author]

Fig. 2. Well deepening parameters in the straight inclined section [compiled by the author]

Drilling at a depth of 3000 m was conducted using the following equipment: a downhole motor with a diameter of 295.3 mm, model A800M 4553 HR-8.92 m; followed by a 269 mm non-magnetic spiral-blade stabilizer (SBS); then a crossover sub with a check valve, 206 mm in diameter, and a 204 mm weighted drill pipe (WDP) measuring 8.93 m. Next, the "Telescope-825NF" telemetry system was installed at 8.06 m, followed by another weighted drill pipe with a diameter of 203 mm and a length of 37.15 m, a hydraulic jar measuring 10.07 m, another weighted drill pipe with a diameter of 203 mm and a length of 9.19 m, a crossover sub, an additional crossover sub, and a weighted drill pipe with a diameter of 172 mm measuring 9.34 m. This assembly was completed with drill pipes running to the wellhead.

To maintain the specified build rate of the zenith angle during angle build-up, the following method was applied: drilling was conducted to a depth of 4–5 m at a specific azimuth with the rotary locked to achieve angle build-up, followed by drilling an additional 4–5 m with rotary motion and a bottom-hole assembly (BHA) configuration to stabilize the zenith angle. This process is illustrated in Column 3 of Fig. 1 by curves showing the rotary speed and the position of the hoisting block.

The technological parameters of well deepening in the straight inclined section were optimized using continuous rotary motion and an appropriate configuration of the bottom-hole assembly (see Fig. 2). The stability of the wellbore trajectory was maintained by adjusting the stabilizer positions in the drill string and alternating between PDC bits and roller-cone bits in the straight section of the well.

At a measured depth of 4450 m, a 244.5 mm casing was successfully run and secured in the well. This process was conducted in two stages. Later, when the well reached the planned depth, a decision was made to continue deepening it for a more detailed study of the productive NK3 horizon layers. The well depth was extended to 4865 m, after which a 139.7 mm production casing was installed.

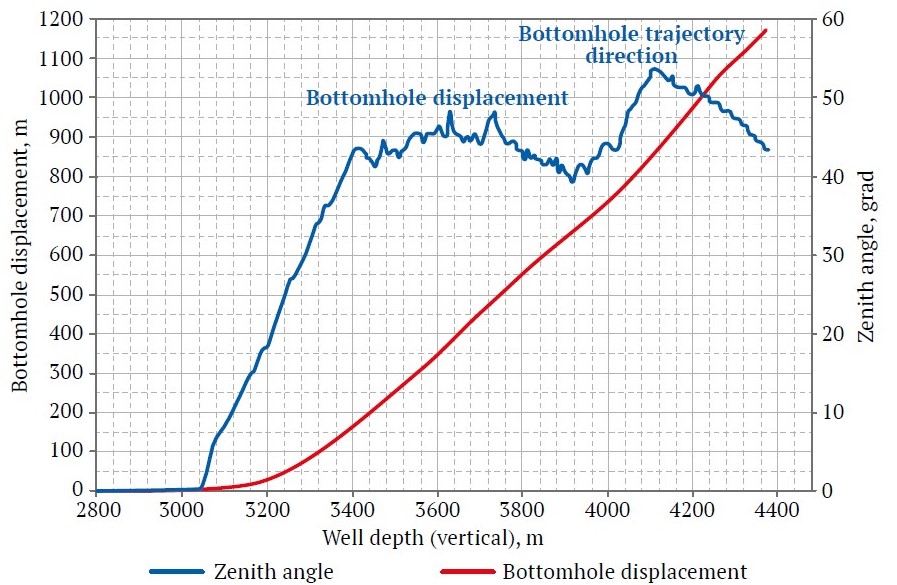

During the drilling of Well X2 at the Northern Goturdepe field, the maximum bottomhole deviation reached 1167.48 m at a magnetic azimuth of 266.15°, and the maximum zenith angle at a depth of 4440 m was 53.46°. The changes in the vertical profile and zenith angle of the well are illustrated in Fig. 3. Production from the first reservoir (NK3) yielded a maximum flow rate of 80 tons per day. The results of the analysis of this product, conducted in the oil, gas, and rock geochemistry laboratory at the Nebitgazylmytaslama Institute, are presented in Table 1.

Fig. 3. Inclination angle change and bottomhole displacement in Well X2 at the Northern Goturdepe field [compiled by the author]

Table 1

Oil analysis from well X2 at the Northern Goturdepe field [compiled by the author]

| Interval (measured depth), m | 4820–4830 | 4832–4844 | |

| Horizon | NK | ||

| Water content, % | 47.0 | 30.5 | |

| Oil density, g/cm³ | 0.8545 | 0.8560 | |

| Pour point, °C | +4 | +4 | |

| Viscosity, Pa·s | 20 °C | 11.4 | 11.5 |

| 50 °C | 5.0 | 5.1 | |

| Conclusion | Liquid hydrocarbon fluid – light oil | ||

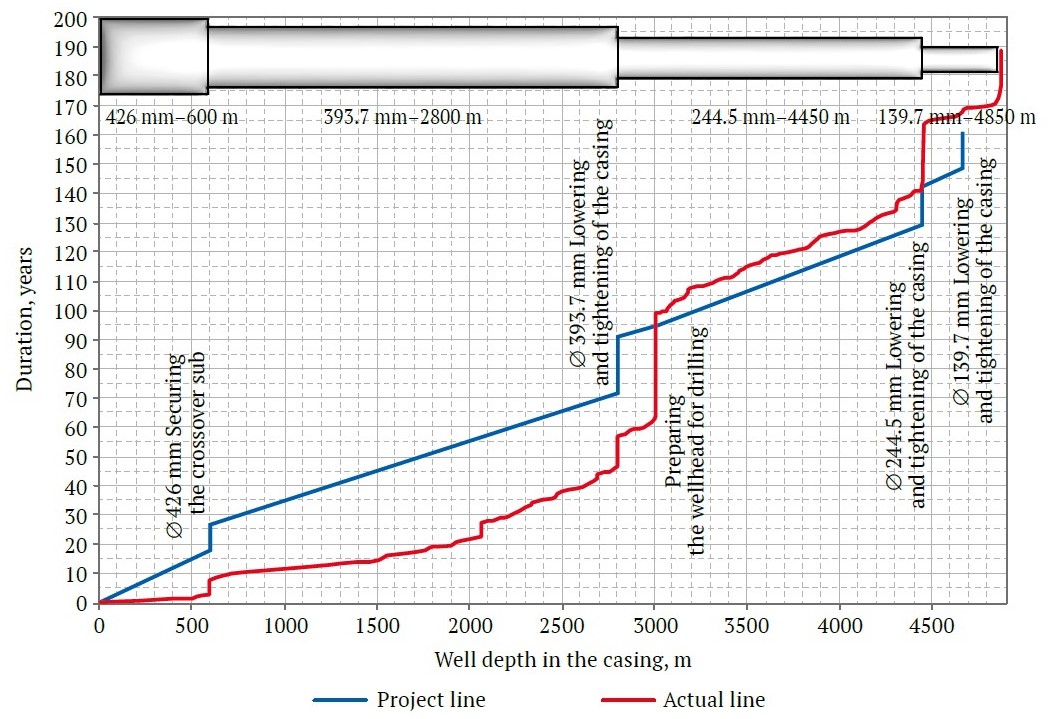

The well construction chart shown in Fig. 4 highlights opportunities to increase drilling speed for this type of well. One of the key factors impacting drilling efficiency and productivity is the reduction of preparation time for drilling the inclined section [17]. In the current chart context, it is evident that the time spent preparing for inclined drilling can be minimized. This is a critical observation, as more efficient and faster preparation for drilling the inclined section will reduce delays and improve overall drilling productivity.

This aspect holds strategic significance, as increasing drilling speed leads to faster hydrocarbon extraction, which, in turn, enhances economic efficiency and provides a quicker return on investment. Such prospects reflect the industry’s commitment to continuously advancing technologies and processes to optimize production and ensure long-term sustainability.

Fig. 4. Timeline diagram of well X2 construction at Northern Goturdepe [compiled by the author]

The commercial productivity of the well is defined by an average drilling speed of 817 m per month, with fully effective drilling time at 100%. The time distribution among main operations is as follows: 27.3% allocated to drilling, 17.2% to tripping operations, 18.06% to casing processes, and 35% to auxiliary tasks. These metrics are crucial for assessing the overall efficiency of the drilling process and provide insights into the time expenditures for each stage of operation.

In conclusion, directional drilling of exploratory wells in the Caspian Sea offshore area represents a complex yet promising path for a country aiming to utilize its natural resources with maximum efficiency. It is essential to strike a balance between economic gains and responsible environmental stewardship to ensure sustainable development and preserve the unique natural environment of this region.

Discussion of the results

Directional drilling of exploratory wells in the Caspian Sea offshore area in Turkmenistan presents both opportunities and challenges. This process holds significant strategic importance for Turkmenistan, which aims to maximize its hydrocarbon extraction potential.

Turkmenistan has substantial oil and gas reserves in the Caspian Sea offshore area. Directional drilling offers a unique opportunity for efficient extraction of these resources. This technology allows for hydrocarbon production from various points within fields, thereby increasing overall output and strengthening the country’s energy security.

The use of directional exploratory wells requires advanced technologies and engineering solutions. Implementing modern drilling and geological exploration methods can significantly improve extraction efficiency and precision. Such innovations not only increase production volumes but also help to reduce the environmental impact.

Serious attention must be given to the environmental and social aspects of offshore drilling in the Caspian Sea. Discharges and emissions can adversely affect the marine ecosystem as well as the health of local communities. Therefore, strict adherence to international standards, the development and deployment of environmentally friendly technologies, and public engagement are key elements of a sustainable approach to hydrocarbon exploration and production.

The success of drilling in the Caspian Sea offshore area also depends on geopolitical factors. Turkmenistan must engage in dialogue and cooperation with neighboring countries that have vested interests in the region. Effective resource management and the resolution of boundary issues contribute to stability and increased investment in the energy sector.

Overall, directional drilling of exploratory wells in the Caspian Sea offshore area in Turkmenistan represents a complex task that requires an integrated approach, balancing interests and considering environmental and social factors. Project implementation that takes these aspects into account can become a key component of sustainable development in the country’s energy sector

According to recent studies by T. Eren, directional drilling positioning calculations play a crucial role in ensuring the accuracy and efficiency of this technological process. The primary goal of these calculations is to precisely determine the well’s coordinates at various depths, allowing engineers and drilling specialists to effectively adjust the drilling direction and angle to meet specific objectives. In directional drilling, tools such as gyroscopes and accelerometers are used to determine the position and angle of the well relative to the vertical axis. This data is then subjected to complex mathematical calculations involving trigonometry and geometry to determine the precise well coordinates at each stage of drilling. Accurate positioning calculations not only enhance hydrocarbon recovery but also reduce the risk of potential issues, such as cross-drilling into neighboring wells or deviating from the target formation. This is especially important in complex geological structures or offshore environments [18].

These findings align with the points discussed in the previous section. Positioning calculations in directional drilling are an integral part of the technology, ensuring process accuracy and efficiency. Modern methods and technologies in this field contribute to the rationalization of hydrocarbon extraction and support sustainable exploration and field development.

According to Fang Peng, the study of key technologies for intelligent directional drilling equipment is a critical aspect in the development of the oil and gas industry. These technologies aim to improve drilling processes, increase accuracy and efficiency, and reduce the risks associated with hydrocarbon extraction. One of the key elements is the use of advanced navigation and control systems, including integrated gyroscopes, accelerometers, and geomagnetic sensors. Intelligent equipment enables real-time monitoring of drilling parameters such as inclination angle, direction, and well depth. Data processing algorithms based on artificial intelligence (AI) allow for the prediction and prevention of potential issues, significantly enhancing drilling safety and productivity. The application of AI technologies also involves automating decision-making processes based on collected data. This enables operators to quickly respond to changing conditions and adjust drilling parameters in real-time, improving performance. Such systems also minimize human involvement in the drilling process, which reduces the risk of accidents and errors [19].

It is worth noting that research on these technologies is directed toward creating sustainable, intelligent drilling systems capable of adapting to various geological conditions. These innovations open up new prospects in hydrocarbon exploration and production, enhancing efficiency and reducing environmental impact.

Researcher H. Li identified that the modified Boltzmann annealing differential evolution algorithm represents an innovative approach to the inversion of directional logging measurements for resistivity during drilling. Log data inversion is a key tool in geophysical research, providing information on rock properties, well characteristics, and the surrounding environment. The differential evolution algorithm combined with the Boltzmann annealing method offers an efficient rationalization method, allowing researchers to determine preferred rock resistivity values in real-time. The algorithm modification is designed to improve its convergence and stability under complex drilling conditions, making it especially useful in oil and gas exploration [20].

This perspective aligns with the view that applying the algorithm to directional logging data enables a more accurate reconstruction of rock resistivity at various well depths. This is crucial for determining rock composition, identifying economically viable zones, and optimizing hydrocarbon production processes. Such innovative inversion methods significantly enhance the accuracy and informativeness of data obtained in real-time during drilling.

Research conducted by D. Cao has demonstrated that the development and application of real-time deep learning models represent significant progress in enhancing the efficiency of directional drilling. This innovative technology relies on neural networks to analyze data collected during drilling and to make decisions based on that analysis. Deep learning enables the creation of complex models capable of automatically extracting high-level features from multidimensional data, such as drilling parameters, geological characteristics, and other factors. These models can predict changes in well geology and prevent potential issues in real-time. The application of real-time deep learning models in directional drilling allows for more precise control and adjustment of drilling direction and angle. This leads to increased productivity, reduced drilling time, and decreased risks of possible failures [21]. These findings support the previous research, as the development and application of real-time deep learning models in directional drilling present the oil and gas sector with opportunities to improve processes, reduce costs, and enhance overall efficiency.

As noted by B. Harris, numerical research on the use of directional wells to extract geothermal energy from abandoned oil and gas wells represents a promising approach that combines high efficiency and sustainability in the renewable energy sector. Abandoned oil and gas wells provide a unique infrastructure that can be repurposed to extract geothermal energy, giving these resources a second life. Numerical modeling allows for the assessment of geothermal energy potential at various depths of abandoned wells, taking into account the geothermal gradient and other geological parameters. The use of directional wells further enhances this process, allowing for more efficient extraction of thermal energy from rock formations. This approach not only enables the reuse of outdated infrastructure but also supports a sustainable and environmentally friendly method of energy production. Energy derived from geothermal sources can serve local power systems and reduce dependency on traditional energy sources [22]. The analysis of the results shows the importance of such studies, as they help to identify effective technologies and geological parameters for utilizing abandoned wells to extract geothermal energy. This direction could contribute to diversifying the energy mix, enhancing its sustainability, and reducing environmental impact.

Researcher A. Ihnatov determined that the development of optimized bottom-hole assemblies (BHAs) for directional drilling is a crucial area in drilling engineering, aimed at streamlining processes and increasing hydrocarbon production efficiency. This task requires a comprehensive approach, including the study of geological features, consideration of well requirements, and the application of advanced engineering solutions. Rational BHAs for directional wells incorporate enhanced drill bits, rotors, and other tools designed specifically for the drilling conditions. Innovative geometries and materials can improve wear resistance, extend equipment life, and reduce maintenance costs. An effective BHA configuration also enables more precise control of drilling direction, which is critical for achieving target objectives in challenging geological conditions. Integrating advanced technologies for drilling process automation and real-time monitoring of wellbore parameters allows for immediate responses to changes, enhancing accuracy and predictability [23].

Thus, the development of optimized BHAs for directional drilling not only contributes to streamlining technological processes but also enhances productivity, reduces risks, and supports the sustainable development of the oil and gas industry.

Conclusions

- The H1 and H2 wells at Northern Goturdepe successfully fulfilled their role in exploration and prospecting activities, confirming the presence of hydrocarbon reserves in this part of the field without the need for additional expenses or time to construct a specialized artificial drilling pad. The experience of drilling a directional well with a curved borehole at the Northern Goturdepe field in Turkmenistan enables the simplification and acceleration of exploration and prospecting activities in the Caspian Sea offshore area. Effective use of existing artificial pads has significantly reduced the financial costs of geological exploration at the Northern Goturdepe field.

- The drilling of directional wells in a field lacking seismic exploration has expanded a significant portion of the field within exploration and prospecting operations. From an ecosystem protection perspective in the Caspian Sea, the use of cluster drilling of directional wells, with minimal creation of new islands, is particularly important.

- Directional drilling in the Caspian Sea enables the efficient extraction of hydrocarbons from various points within fields, which is essential given the complex geology. Streamlining drilling processes with consideration for well orientation helps improve overall productivity and reduce delays. This approach not only increases energy resource production but also supports operational sustainability and enhances economic efficiency. The development of technologies, such as modern navigation and control systems, complements the drilling process, ensuring accuracy and safety.

- Drilling in the Caspian Sea offshore area in Turkmenistan is becoming an essential component of the country's energy strategy, and the effective use of directional exploratory wells reflects a continuous commitment to innovation and technological improvement in the oil and gas industry.

- It is necessary to further study the environmental impact and ecosystem effects of directional drilling processes in the Caspian Sea offshore area in Turkmenistan to develop more ecologically sustainable and socially responsible approaches to energy resource extraction.

- The conclusions drawn from directional exploratory drilling in the Caspian Sea offshore area in Turkmenistan highlight the strategic importance of this approach for hydrocarbon production in the region. Turkmenistan, with its vast oil and gas reserves, is actively implementing innovative drilling methods to maximize production efficiency.

References

1. Geldimyradov A. G. Determination of formation parameters based on studies of pressure change curve under conditions of gas wells of Turkmenistan. In: Science, Society, Technology: Problems and Prospects for Interaction in the Modern World. Collection of articles of the International Scientific and Practical Conference. Petrozavodsk, February 17, 2022. Petrozavodsk: International Center for Scientific Partnership "Novaya Nauka"; 2022. Pp. 150-163. (In Russ.) https://doi.org/10.46916/21022022-1-978-5-00174-478-8

2. Pulatov B. R. Technological aspects and emerging complications when drilling wells in rapiferous zones. Innovation in the Oil and Gas Industry. 2021;2(3):103–114. (In Russ.) URL: https://tadqiqot.uz/index.php/petroleum/article/view/4232/4015

3. Kholbaev, B. M., & Muhammadiev, Sh. Sh. (2023). Selection of the type of drilling fluid for drilling wells. Innovative Development in Educational Activities. 2023;2(8):684–686. (In Russ.)

4. Deryaev A. Features of the construction of directional deep wells in Turkmenistan, Neftyanoe Khozyaystvo 2024;(2):43–47. (In Russ.) https://doi.org/10.24887/0028-2448-2024-2-43-47

5. Amanniyazov Y., Nurlyev B., Akmukhammedov M. Drilling fluids. Their role in the drilling process. In: Modern Tasks and Promising Directions for Innovative Development in Science. Collection of articles based on the results of an international scientific and practical conference. Irkutsk, February 09, 2023. Sterlitamak: AMI; 2023. Pp. 87–88. (In Russ.) URL: https://ami.im/sbornik/MNPK-458.pdf#page=87

6. Geldiev Sh., Ovezmammedov B. Analysis and identification of factors of the impact of the development of the fuel and energy complex on the development of Turkmenistan. In: Science Innovations – 2022. Collection of articles of the international scientific and practical conference. Petrozavodsk, October 31, 2022. Petrozavodsk: International Center for Scientific Partnership "Novaya Nauka"; 2022. (In Russ.)

7. Bashir B., Piaskowy M., Alusta G. Overview on directional drilling wells. ARPN Journal of Engineering and Applied Sciences. 2021;16(22):2305–2316.

8. Njuguna J., Siddique S., Kwroffie L. B. et al. The fate of waste drilling fluids from oil & gas industry activities in the exploration and production operations. Waste Management. 2022;139:362–380. https://doi.org/10.1016/j.wasman.2021.12.025

9. Magana-Mora A., Affleck M., Ibrahim M. et al. Well control space out: A deep-learning approach for the optimization of drilling safety operations. IEEE Access. 2021;9:76479–76492. https://doi.org/10.1109/ACCESS.2021.3082661

10. Deryaev A. R. Drilling horizontal wells in Western Turkmenistan. SOCAR Proceedings Special. 2023;(2):32–40. (In Russ.) http://dx.doi.org/10.5510/OGP2023SI200877

11. Deryaev A. R. Development of well design for multi-layer fields for the purpose of simultaneous separate operation of one well. SOCAR Proceedings. 2022;(1):94–102. http://dx.doi.org/10.5510/OGP20220100635

12. Mohamed A., Salehi S., Ahmed R. Significance and complications of drilling fluid rheology in geothermal drilling: A review. Geothermics. 2021;93:102066. https://doi.org/10.1016/j.geothermics.2021.102066

13. Tewari S., Dwivedi U. D., Biswas S. Intelligent drilling of oil and gas wells using response surface methodology and artificial bee colony. Sustainability. 2021;13(4):1664. https://doi.org/10.3390/su13041664

14. Li Y., She L., Wen L., Zhang Q. Sensitivity analysis of drilling parameters in rock rotary drilling process based on orthogonal test method. Engineering Geology. 2020;270:105576. https://doi.org/10.1016/j.enggeo.2020.105576

15. Sun J., Chen M., Li Q., et al. A new method for predicting formation lithology while drilling at horizontal well bit. Journal of Petroleum Science and Engineering. 2021;196:107955. https://doi.org/10.1016/j.petrol.2020.107955

16. Fabre C. Advances in Laser-Induced Breakdown Spectroscopy analysis for geology: A critical review. Spectrochimica Acta Part B: Atomic Spectroscopy. 2020:166:105799. https://doi.org/10.1016/j.sab.2020.105799

17. Huque M. M., Rahman M. A., Zendehboudi S. et al. Experimental and numerical study of cuttings transport in inclined drilling operations. Journal of Petroleum Science and Engineering. 2022;208:109394. https://doi.org/10.1016/j.petrol.2021.109394

18. Eren T., Suicmez V. S. Directional drilling positioning calculations. Journal of Natural Gas Science and Engineering. 2020;73:103081. https://doi.org/10.1016/j.jngse.2019.103081

19. Fang P., Yao K., Wang L. et al. Research on key technologies of the ZDY25000LDK intelligent directional drilling equipment. Coal Geology & Exploration. 2022;50(1):2. https://doi.org/10.12363/issn.1001-1986.21.10.0597

20. Li H., Wang H., Wang L., Zhou X. A modified Boltzmann Annealing Differential Evolution algorithm for inversion of directional resistivity logging-while-drilling measurements. Journal of Petroleum Science and Engineering. 2020;188:106916. https://doi.org/10.1016/j.petrol.2020.106916

21. Cao D., Hender D., Ariabod S. et al. The development and application of real-time deep learning models to drive directional drilling efficiency. In: IADC/SPE International Drilling Conference and Exhibition. Galveston, Texas, USA, March 3–5, 2020. https://doi.org/10.2118/199584-MS

22. Harris B. E., Lightstone M. F., Reitsma S. A numerical investigation into the use of directionally drilled wells for the extraction of geothermal energy from abandoned oil and gas wells. Geothermics. 2021;90:101994. https://doi.org/10.1016/j.geothermics.2020.101994

23. Ihnatov A., Koroviaka Y., Rastsvietaiev V., Tokar L.. Development of the rational bottomhole assemblies of the directed well drilling. In: E3S Web of Conferences. IV International Scientific and Technical Conference “Gas Hydrate Technologies: Global Trends, Challenges and Horizons” (GHT 2020). 2021;230:01016. https://doi.org/10.1051/e3sconf/202123001016

About the Author

A. R. DeryaevTurkmenistan

Annaguly R. Deryaev – Dr. Sci. (Eng.), Principal Researcher

Ashgabat

Scopus ID 57929694600, ResearcherID HPB-6027-2023

Review

For citations:

Deryaev A.R. RETRACTED: Directional drilling of an exploratory well in the shallow waters of the Caspian Sea. Mining Science and Technology (Russia). 2024;9(4):341-351. https://doi.org/10.17073/2500-0632-2024-02-217