Scroll to:

Application of hydrodynamic simulation on the basis of a composite model to improve the efficiency of gas-condensate reservoir development

https://doi.org/10.17073/2500-0632-2023-10-176

Abstract

At the moment, the use of digital models in the development of oil and gas fields is an effective tool for making informed tactical and strategic decisions to maximize the extraction of hydrocarbon reserves in a field. At the same time, the permanent increase in the share of hard-to-recover reserves leads to an accelerated increase in the role of simulation of reservoir hydrocarbon systems in the development of oil and gas fields. Many gas-condensate fields in Eastern Siberia can be characterized as reservoirs with low permeability and porosity and difficult thermobaric conditions, and, as a result, the issue of improving the efficiency of the development of such reservoirs to increase the cumulative production of gas and condensate is relevant. If the initial reservoir pressure of a gas-condensate field corresponds to the dewpoint pressure, dropout of a significant amount of retrograde condensate is observed when the pressure in the reservoir decreases. Condensate dropout in the pore space of a reservoir leads to a decrease in both the condensate recovery factor (CRF) and the gas recovery factor (GRF). The predictive calculations of the development of a gas-condensate reservoir by vertical and horizontal wells were carried out with the use of the hydrodynamic simulator T-Navigator of a domestic manufacturer Rock Flow Dynamics. The calculations were performed under various process conditions on the example of a gas-condensate field, which is characterized by complicated thermobaric conditions (the initial reservoir pressure corresponds to the dewpoint pressure), while the target process parameter was the amount of condensate dropout in the reservoir. Based on the results of the study, the main conclusion can be drawn. The development of the reservoir by horizontal wells can significantly reduce the reservoir drawdown pressure compared to vertical wells, while the condensate dropout in the reservoir occurs in a larger volume; the condensate becomes immobile and prevents further gas production, reducing the total production of condensate. An increase in reservoir condensate recovery in the course of the development of a gas-condensate reservoir by vertical wells compared to horizontal wells is observed under certain reservoir conditions corresponding to the simulation performed in this study, namely, at low reservoir permeability and porosity and the presence of a saturated gas-condensate system.

Keywords

For citations:

Tomskiy K.O., Ivanova M.S., Nikitin E.D., Rudykh L.A. Application of hydrodynamic simulation on the basis of a composite model to improve the efficiency of gas-condensate reservoir development. Mining Science and Technology (Russia). 2024;9(3):221-230. https://doi.org/10.17073/2500-0632-2023-10-176

Application of hydrodynamic simulation on the basis of a composite model to improve the efficiency of gas-condensate reservoir development

Introduction

At present, the use of geological and hydrodynamic simulation in the development of oil and gas fields is an effective way to make informed tactical and strategic decisions for the effective extraction of hydrocarbon reserves in a field. At the same time, the permanent increase in the share of hard-to-recover reserves leads to an accelerated increase in the role of simulation of reservoir hydrocarbon systems in the development of oil and gas fields [1–3].

The most common model in the development of oil and gas fields is a non-volatile oil model, in which an oil and gas system is simulated using two components: oil and gas, which, in turn, can be dissolved in oil [4–6].

The simulation of a gas-condensate reservoir requires a complex compositional model of threephase filtration, due to the fact that, when developing a gas-condensate reservoir, it is necessary to take into account the actual composition of the reservoir fluid [7–9].

When the pressure isothermal drops below a critical point (dewpoint) during development, the phenomenon of retrograde condensation occurs in the pore space of the reservoir. Fields with such characteristics are called gas-condensate fields [10–12].

The intensity of gas-condensate dropout, in addition to pressure, also depends on the component composition and physical and chemical properties of the phases. Changes in fluid composition occur under the influence of depth, surface tension, and viscosity. At the same time, a decrease in the cross-section of filtration channels leads to a decrease in permeability and, correspondingly, to a decrease in productivity [13–15].

The use of horizontal wells in comparison with vertical wells leads to a decrease in the reservoir drawdown pressure, which leads to less condensate dropout in the pore space and, correspondingly, to an increase in the final condensate recovery in the field. At the same time, it should be noted that there are few comparative studies of the use of horizontal and vertical wells in conditions of low reservoir permeability in order to increase the final condensate recovery [16–18].

The purpose of this work is to select the optimal option of a field development using hydrodynamic simulation to increase condensate recovery of a gas-condensate field characterized by low permeability and porosity and initial reservoir pressure equal to the dewpoint pressure.

In order to achieve the goal, the following tasks were solved in the study:

- construction of two options for the development of a gas-condensate reservoir based on a hydrodynamic composite model: development by vertical wells (option 1) and horizontal wells (option 2);

- comparative analysis of the proposed options for the development of a gas-condensate reservoir characterized by low permeability and porosity.

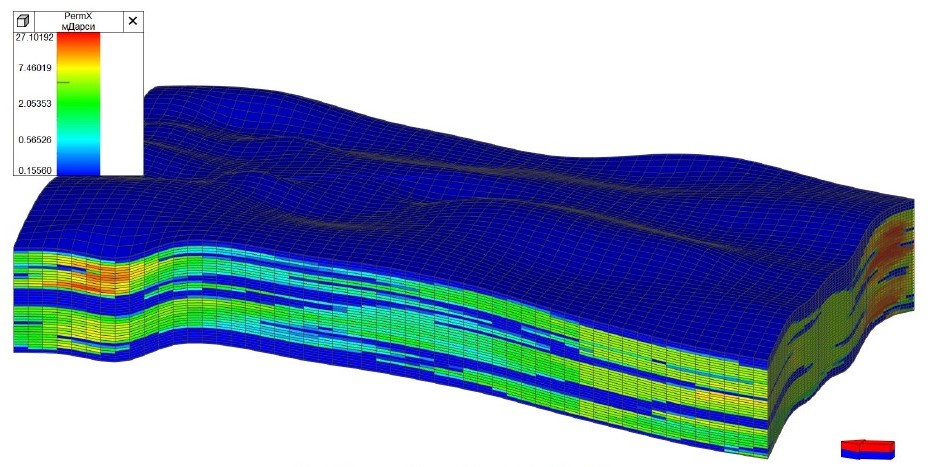

Description of the composite model: the hydrodynamic model (Fig. 1) is represented by a selected fragment of the field.

Parameters adopted for simulation:

Height along Z (average) – 35.7 m;

Initial reservoir pressure – 29.1 MPa;

Reference depth – 2860 m;

Initial reservoir temperature – 80 °C;

Porosity – 0.09 – 0.169, decimal quantities;

Horizontal permeability – 0.0001556 – 0.0271019 μm2;

Net/gross ratio (NTG) (average) – 0.6572, decimal quantities.

Reservoir gas component composition:

СО2 – 0.273; N2 – 1.045; СН4 – 80.842; С2Н6 – 6.044; С3Н8 – 3.761; iС4Н10 – 0.790;

nС4Н10 – 0.921; С5Н12 and higher – 6.324 % mole.

Properties of the gas-condensate fluid:

Reservoir pressure – 29.10 MPa; Temperature – 80 °C; potential condensate content – 290 g/m3; mole fraction of dry gas – 0.937 decimal quantities; supercompressibility coefficient under initial conditions – 0.902; fluid dewpoint pressure – 29.10 MPa [19].

Fluid properties were simulated based on the data from gas-condensate studies. Based on the data on the composition and properties of the reservoir fluid obtained in the process of laboratory experiments, a composite model of the fluid was created.

Fig. 1. Reservoir model used in calculations

Research Methodology

One of the ways to rationally increase the profitability of the development of gas and gas-condensate fields with productive formations with low reservoir permeability and occurring at great depths is the shift to a development system using horizontal wells. The main advantages of horizontal wells are an increase in the area of reservoir fluid filtration through the well walls and a decrease in a productive reservoir drawdown, which makes it possible to ensure sufficiently high gas and gas-condensate flow rates in low-permeability and low-capacity reservoirs, as well as to reduce the number of required production wells in a field.

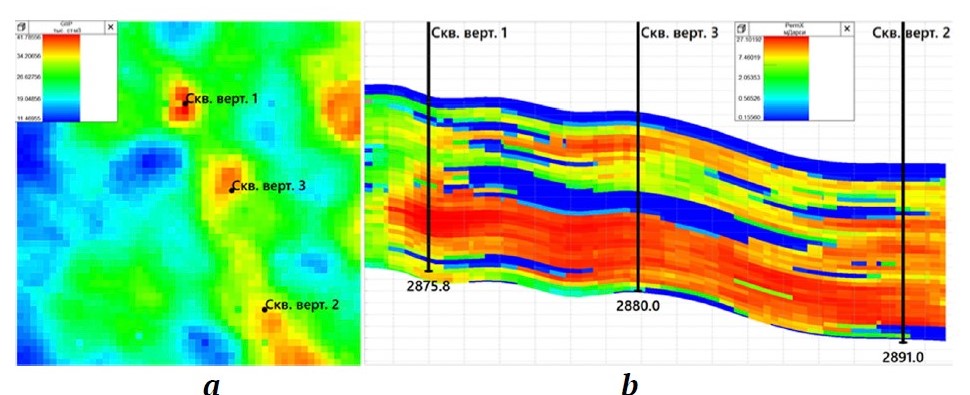

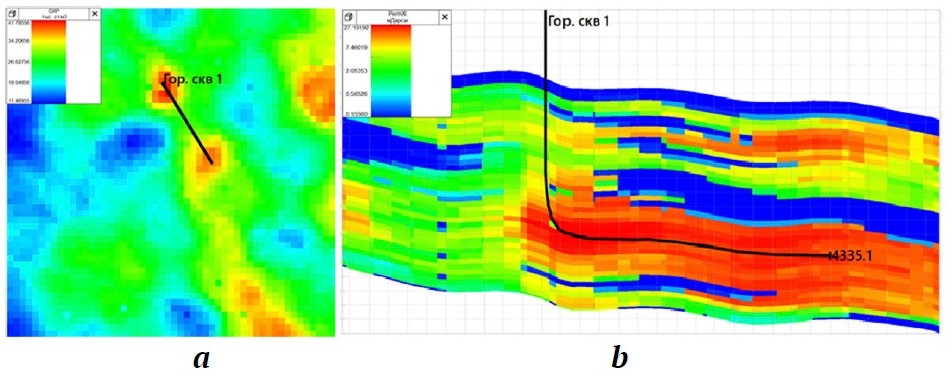

Two options for reservoir development were considered in the work: three vertical wells – option 1; one horizontal well with a horizontal section length of 1,400 m – option 2 [19–21].

The selection of three vertical wells versus one horizontal well, as well as the length of the horizontal wellbore, was justified by the economic costs of well construction. Well positioning was based on the map of initial gas reserves and permeability, as well as on maps of the initial net gas thickness of the reservoir (Fig. 2, 3). In other words, the two options considered are comparable in terms of well construction costs. In case of a change in the number of wells, namely additional drilling of a horizontal well or consideration of only two vertical wells as the first option – the conditions for the comparability of initial construction costs change.

Fig. 2. Option 1 on the initial reserve map (a) and permeability map (b)

Fig. 3. Option 2 on the initial reserve map (a) and permeability map (b)

Drawdown and gas withdrawal were taken as variable parameters for well operation. According to the accepted minimum possible bottomhole pressure in the field conditions, it was decided to switch to a bottomhole pressure of 3.5 MPa in case of failure to achieve the target indicators for flow rate and drawdown.

Further, the main indicators of the development of the reservoir fragment were calculated and compared with each other to find the most profitable option in terms of gas and gas-condensate production both in terms of well design (three vertical or one horizontal) and in terms of process conditions of operation.

The parameters of the process conditions of well operation adopted in the simulation for the options: gas flow rate of 600, 900, 1,500, and 2,100 thousand m3/day for one horizontal well; gas flow rate of 200, 300, 500, and 700 thousand m3/day for one vertical well; drawdown of 2, 3, 4, 5, and 6 MPa for each of the three vertical wells.

These parameters of the process conditions lie within the range of the changes in the actual parameters of the operation of vertical wells in the field.

Discussion

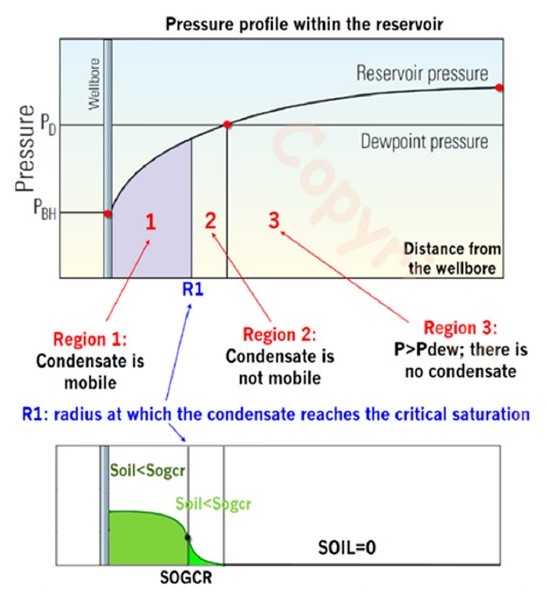

When developing a model of a gas-condensate reservoir with vertical wells, it is necessary to maintain significantly higher drawdowns compared to horizontal wells in order to achieve comparable flow rates. In this regard, in the case of vertical wells, there is a sharper drawdown in the bottomhole zone of a well, which causes more condensate dropout near the well, which ultimately leads to a decrease in the gas permeability of the bottomhole zone of a well. At the same time, at a certain distance from a well, smaller drawdowns are observed compared to the near-well zone, which ultimately leads to a greater amount of condensate dropout in the bottomhole zone compared to the rest of the reservoir. It is known that in the process of dropout, condensate forms three different areas of mobility near a vertical wellbore. In two of these zones, gas-condensate is present in mobile and immobile forms (Fig. 4) [9]. Correspondingly, most of the condensate in the bottomhole zone of a vertical well will occur in a mobile form.

Fig. 4. Reservoir gas-condensate flow diagram [9]

However, at the moment, there are very few studies regarding condensate dropout when using horizontal wells. In the case of developing a model of a gas-condensate reservoir with horizontal wells, we observe significantly lower drawdowns and high coverage of the reservoir by a horizontal wellbore, which, in turn, leads to condensate dropout at significant distances from the well, but in a smaller amount than in the bottomhole zone in the case of vertical wells. At the same time, the condensate formed (dropout) at considerable distances from a horizontal well will exist in an immobile form. As a result, this leads to an overall loss of cumulative condensate production.

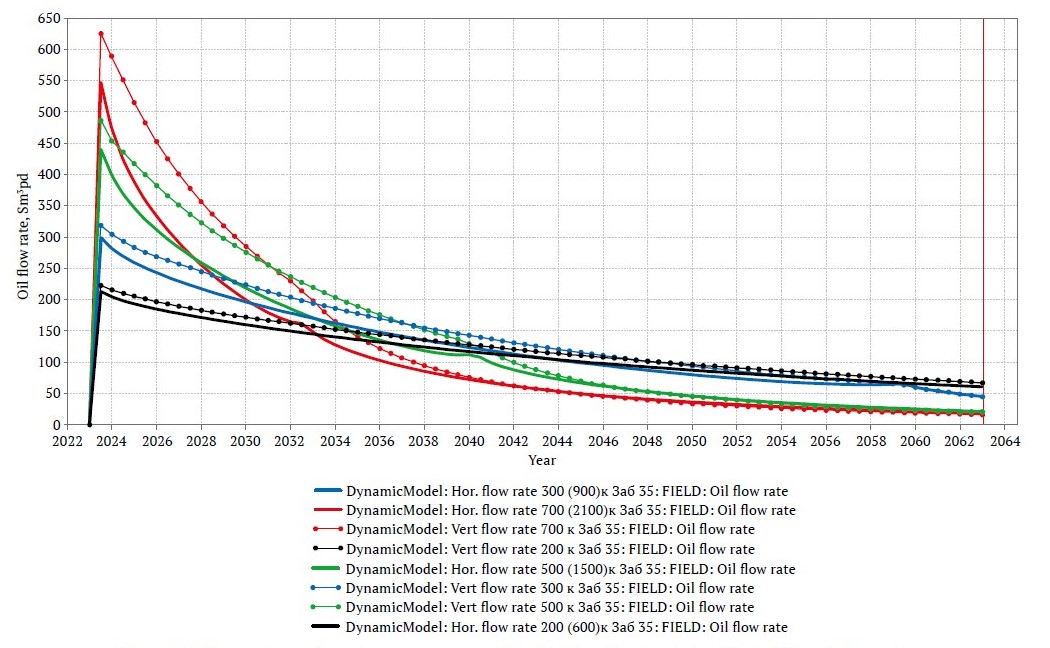

Fig. 5 shows the change in condensate recovery (oil flow rate in the designation of the vertical axis) for a forecast period of 40 years with different flow rates of vertical wells. The figure shows that with high gas withdrawals (black line – 900 thousand m3), at first, more condensate is produced, but then there is an intensive decrease in its production due to a large pressure gradient, leading to more condensate dropout in the reservoir. It can also be seen that with gas withdrawals of 200 thousand m3/day (lilac line) the condensate flow rate is more uniform, and after 40 years of operation in this case, the maximum value of condensate recovery is observed, but the optimal amount of extraction should be selected based on the economic feasibility of developing the reservoir.

Fig. 5. Condensate recovery time dependence at different gas flow rates in the case of vertical wells (option 1)

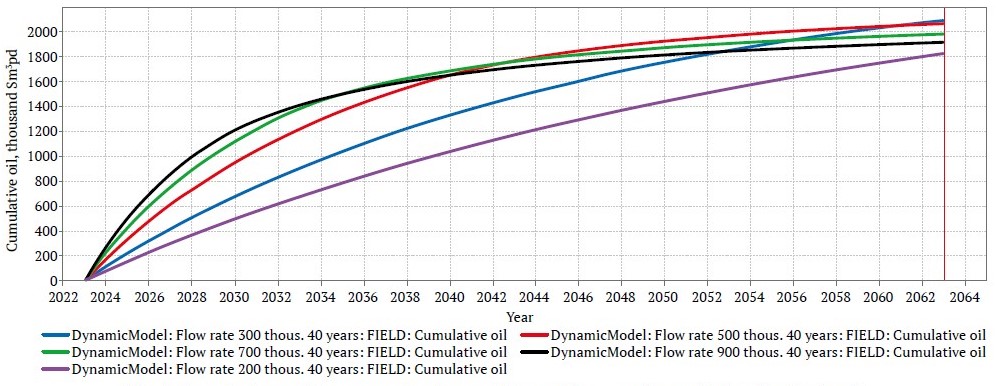

For optimal development mode and maximum condensate recovery over a given period of time, the flow rate level is selected that would justify from an economic point of view the extraction of gas reserves with a sufficient amount of condensate produced. Fig. 6 shows that the maximum condensate recovery (2,100 m3) is achieved at a gas flow rate of 300 thousand m3/day (blue line) for the period of well operation of 40 years.

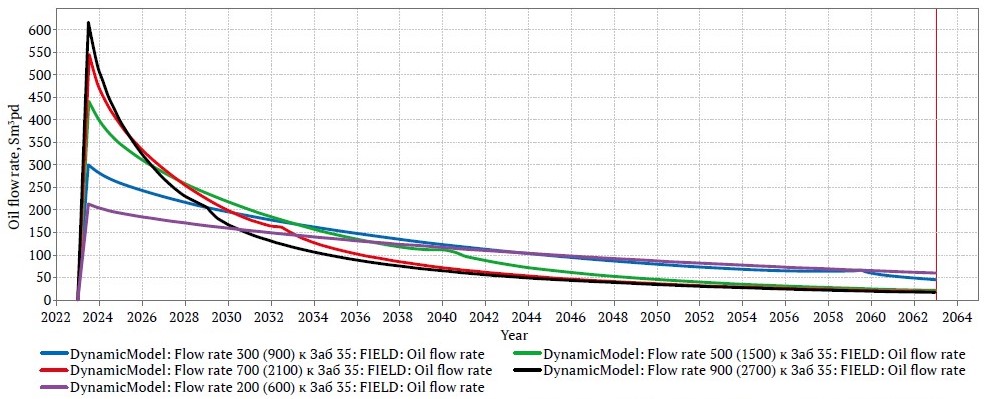

Fig. 7 shows the condensate recovery time dependence at different flow rates of a horizontal well. Value of condensate recovery of a horizontal well at a flow rate of 2,700 thousand m3/day corresponds to 620 m3/day, while in the case of a vertical well with a flow rate of 900 thousand m3/day (while the total flow rate of three vertical wells will also correspond to 2,700 thousand m3/day), the condensate recovery corresponds to 760 m3/day (see Fig. 5). Besides, on the graphs, we can observe certain “jumps”, which

Fig. 6. Cumulative condensate production at different flow rates for vertical wells (Option 1)

Fig. 7. Condensate recovery time dependence at different gas flow rates in the case of a horizontal well (Option 2)

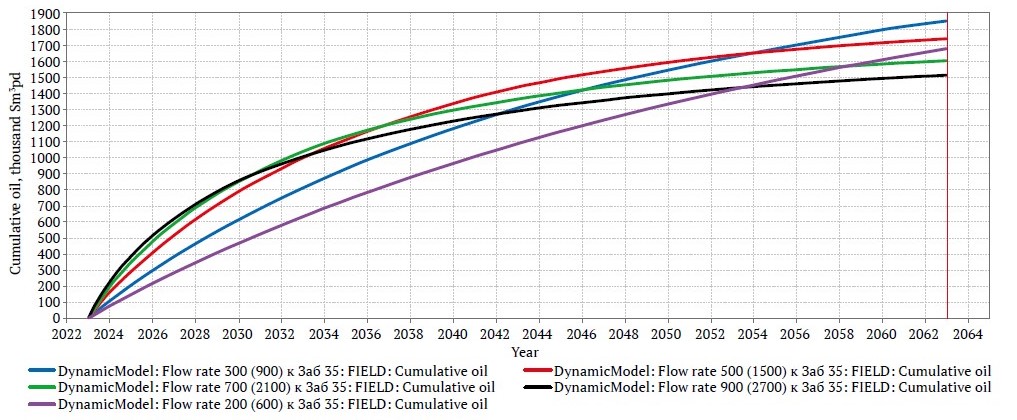

Fig. 8 shows time dependencies of cumulative condensate production in the case of a horizontal well. The maximum cumulative condensate production is observed, same to the case of vertical wells, at a horizontal wellbore flow rate of 900 thousand m3/day (corresponds to the case of a vertical well flow rate of 300 thousand m3/day). However, the cumulative condensate production for a horizontal well over a 40-year operation period reaches 1,850 m3/day, while in the case of vertical wells it is 2,100 m3/day.

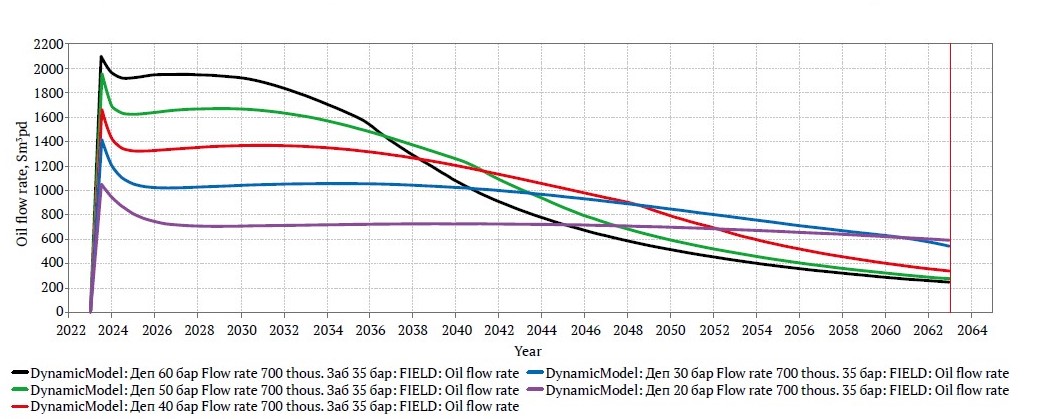

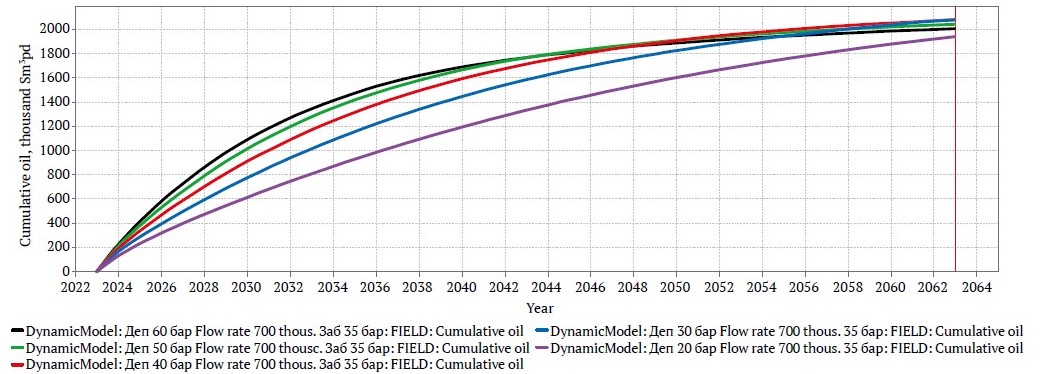

Fig. 9 presented gas flow rate graph for three vertical wells at different drawdowns corresponding to 2, 3, 4, 5, and 6 MPa (with a target flow rate of 700 thousand m3/day) with the subsequent change to the bottomhole pressure control mode of 3.5 MPa if it is impossible to maintain the preset values of drawdowns. Analysis of the graphs shows that the lower the drawdown, the more steadily the required flow rates can be maintained during the life of a well.

Fig. 10 shows time dependencies of cumulative condensate production at different drawdowns of vertical wells corresponding to 2, 3, 4, 5, and 6 MPa (with a target flow rate of 700 thousand m3/day). Analysis of the graphs shows that the optimal drawdown in the case of a prognosis for 40 years is 3 MPa.

Fig. 11 shows comparative condensate recovery graphs in the cases of gas-condensate reservoir development by vertical and horizontal wells. The analysis shows that the condensate recovery of horizontal wells in all cases will be less than that of vertical wells. In the case of high initial flow rates, a comparability of the condensate recovery of the two options after 20 years of operation is observed, while in the case of low initial flow rates (200 thousand m3/day for vertical wells and 600 thousand m3/day for a horizontal well), the excess of condensate recovery of vertical wells compared to horizontal wells is observed during the entire development period.

Fig. 8. Cumulative condensate production at different flow rates in the case of a horizontal well (Option 2)

Fig. 9. Graph of changes in gas flow rates for three vertical wells at different drawdowns of 2, 3, 4, 5, and 6 MPa (Option 1)

Fig. 10. Cumulative condensate production at different drawdowns for vertical wells (Option 1)

Fig. 11. Comparison of condensate recovery of vertical and horizontal wells at different flow rates (Options 1 and 2)

Conclusions

1. Using hydrodynamic simulation based on a multicomponent (compositional) model, a comparative analysis of the development of a gas-condensate reservoir by vertical and horizontal wells was carried out, the results of which revealed the advantage of reservoir development by vertical wells compared to horizontal wells in terms of maximum condensate recovery. Field development by horizontal wells can significantly reduce reservoir drawdown compared to vertical wells, with condensate dropout in the reservoir in large volume, becoming immobile and preventing further gas production, while reducing overall condensate production. An increase in reservoir condensate recovery in the course of the development of a gas-condensate reservoir by vertical wells compared to horizontal wells is observed under certain reservoir conditions corresponding to the simulation performed in this study, namely, at low reservoir permeability and porosity and the presence of a saturated gas-condensate system (the dewpoint pressure corresponds to the initial reservoir pressure).

2. A further more in-depth analysis of the development of a gas-condensate reservoir characterized by low permeability and porosity by horizontal wells is required from the point of view of other options for the optimal location of a horizontal wellbore in the reservoir in comparison with other options for the location of vertical wells in order to determine the area of occurring immobile condensate during the development, which ultimately has a significant impact on the cumulative condensate production.

References

1. Aziz Kh., Settari A. Petroleum reservoir simulation. London: Applied Science Publishers LTD; 1979. (Trans. ver.: Aziz Kh., Settari A. Petroleum reservoir simulation. 2 nd ed. Moscow-Izhevsk: Institute of Computer Technology; 2004. 416 p. (In Russ.)

2. Pyatibratov P. V. Hydrodynamic simulation of oil field development. Мoscow: Russian State University of Oil and Gas named after I. M. Gubkin Publ.; 2015. 167 p. (In Russ.)

3. Tomskiy K. O., Ivanova M. S., Oshchepkov N. S., Sokolov N. G. Determining the optimal location of a multilateral fishbone well, taking into account the peculiarities of the Srednebotuobinskoye oil and gas condensate eld using hydrodynamic modeling. Mathematical notes of NEFU. 2022;29(4):95–112. (In Russ.) https://doi.org/10.25587/SVFU.2023.68.12.008

4. Kanevskaya R. D. Mathematical simulation of hydrodynamic processes of hydrocarbon field development. Moscow-Izhevsk: Institute for Computer Research Publ.; 2002. 140 p. (In Russ.)

5. Abasov M. T., Orudzhaliyev F. G. Gas hydrodynamics and development of gas-condensate fields. Мoscow: Nedra Publ.; 1989. 262 p. (In Russ.)

6. Rodriguez F., Sancehs J., Galindo-Nava A. Mechanisms and main parameters affecting nitrogen distribution in the gas cap of the supergiant akal reservoir in the Cantarell Complex. In: SPE Annual Technical Conference and Exhibition. Houston, Texas, September 2004. https://doi.org/10.2118/90288-MS

7. Holditch S. A., Spivey J., Wang J. Y. Case history of a tight and abnormally pressured gas condensate reservoir. In: SPE California Regional Meeting. California, USA, 1985.

8. Afidick D., Kaczorowski N. J., Bette S. Production performance of retrograde gas reservoir: A case study of Arun field. In: SPE Asia Pacific Oil and Gas Conference. 1994.

9. Fan L., Harris B. W., Jamaluddin A., et al. Understanding gascondensate reservoirs. Oilfield Review. 2005;17(4):14–27.

10. Ursin J. R. Fluid flow in gas condensate reservoirs: The interplay of forces and their relative strengths. Journal of Petroleum Science and Engineering. 2004;(4):253–267. https://doi.org/10.1016/j.profnurs.2003.09.005

11. Moses P. L., Wilson K. Phase equilibrium considerations in using nitrogen for improved recovery from retrograde condensate reservoirs. Journal of Petroleum Technology. 1981;33(02):256–262. https://doi.org/10.2118/7493-PA

12. Bergenov S. U., Chernova O. S., Zipir M. G. Methodology for assessing the expected starting flow rates of horizontal wells in gas and gas condensate fields. Bulletin of the Tomsk Polytechnic University. Geo Assets Engineering. 2020;331(3):207–212. (In Russ.) https://doi.org/10.18799/24131830/2020/3/2563

13. Aliev Z. S., Marakov D. A. Transition zone impact on reliability of gas reserves and well productivity. Petroleum and Gas: Experiens and Innovation. 2017;1(1):3–12. (In Russ.)

14. Fevang O., Whitson C. H. Modeling gas-condensate well deliverability. SPE Reservoir Evaluation and Engineering. 1996;11(4):221–222. https://doi.org/10.2118/30714-PA

15. Shandrygin A. N., Kazantsev M. A., Morev M. V., Badalov E. Z. Methodology for determining the productivity of horizontal wells based on the data of hydrodynamic modeling and exploration wells in gas condensate fields. Science & Technology in the Gas Industry. 2021;(2):52–59. (In Russ.)

16. Sayed M. A., Muntasheri G. A. Mitigation of the effects of condensate banking: a critical review. SPE Production & Operations. 2016;31(02):85–102. https://doi.org/10.2118/168153-PA

17. Nikolaev O. V., Shandrygin A. N., Baiburin R. A. et al. Optimization of the design and operation modes of horizontal holes in gas-condensate fields with complicated geological and climatic conditions. Nauka i Tekhnika v Gazovoy Promyshlennosti. 2021;(2):74–81. (In Russ.)

18. Hale P., Lokhandwala K. Advances in membrane materials provide new gas processing solutions. In: Proceedings of the Laurance Reid Gas Conditioning Conference. Norman, Oklahoma, USA, 2004. Pp. 165–182.

19. Tomskiy K. O., Nikitin E. D., Ivanova M. S. Analysis of the effectiveness of applying horizontal wells for the development of reserves of a gas condensate field with low filtration and capacitance properties. Bulletin of the Tomsk Polytechnic University. Geo Assets Engineering. 2023;(9):172–181. (In Russ.)

20. Brusilovsky A. I. Phase transformations in the development of oil and gas fields. Мoscow: Graal Publ.; 2002. 575 p. (In Russ.)

21. Redlich O., Kwong J. N. S. On the thermodynamics of solutions: V: An equation of state. Fugacities of gaseous solutions. Chemical Reviews. 1949;44(1):233–244. https://doi.org/10.1021/cr60137a013

About the Authors

K. O. TomskiyRussian Federation

Kirill O. Tomskiy – Cand. Sci. (Eng.), Head of the Department of Subsoil Use

Scopus ID 58080759000

Yakutsk

M. S. Ivanova

Russian Federation

Mariya S. Ivanova – Cand. Sci. (Chem.), Associate Professor of the Department of Subsoil Use

Scopus ID 7202135803

Yakutsk

E. D. Nikitin

Russian Federation

Egor D. Nikitin – PhD-Student of the Department of Information and Communication Technologies

Moscow

L. A. Rudykh

Russian Federation

Lyubov A. Rudykh – Student of the Basic Department of Taas-Yuryakh Neftegazodobycha LLC, PJSC NK Rosneft, Polytechnic Institute (branch) Northeastern Federal University in Mirny

Mirny

Review

For citations:

Tomskiy K.O., Ivanova M.S., Nikitin E.D., Rudykh L.A. Application of hydrodynamic simulation on the basis of a composite model to improve the efficiency of gas-condensate reservoir development. Mining Science and Technology (Russia). 2024;9(3):221-230. https://doi.org/10.17073/2500-0632-2023-10-176