Scroll to:

Assessment of readiness of auxiliary mine rescue teams in coal mines

https://doi.org/10.17073/2500-0632-2024-03-234

Abstract

The efficiency of mine rescue operations largely depends on how quickly efforts to localize and mitigate an accident are initiated. Given the remoteness of some mining enterprises, a decision was made to form auxiliary mine rescue teams composed of miners. However, there is ongoing debate regarding the effectiveness of the rescue operations carried out by these auxiliary teams. This paper presents data on the assessment of the readiness of auxiliary mine rescue teams in Russian coal mines. A survey of professional mine rescuers was conducted across all units and platoons, focusing on key aspects of auxiliary team operations. The results, based on expert evaluations, revealed the main challenges in training auxiliary team members and highlighted areas for improving the regulatory and methodological framework for mine rescue tactics. The second part of the paper presents the results of control-tactical exercises held at seven mines. These unannounced exercises took place at the end of a work shift and evaluated a wide range of knowledge, skills, abilities, and physical fitness among the auxiliary teams. Key evaluations included the accuracy of task allocation, tactical training, preparation for mine descent, the use of rescue equipment, first aid skills, theoretical knowledge, and physical fitness.

Keywords

For citations:

Rudenko V.A. Assessment of readiness of auxiliary mine rescue teams in coal mines. Mining Science and Technology (Russia). 2024;9(3):243-249. https://doi.org/10.17073/2500-0632-2024-03-234

Assessment of readiness of auxiliary mine rescue teams in coal mines

Introduction

The safety of mining operations is directly influenced by the qualifications of miners and technical staff. Currently, 38 higher education institutions and 114 colleges in Russia provide training for the mining industry [1, 2]. However, training in mining safety and mine rescue (a mandatory discipline) varies significantly in quality across educational institutions, with instructors of differing qualifications and often insufficient training facilities [3, 4]. Accidents in mining enterprises usually occur due to the low qualification of employees [5]. Moreover, only a few universities offer in-depth training in mine rescue [4, 6]. Abroad, where mine rescue is more advanced, there are no auxiliary mine rescue teams1 [7]. In Russia, the preparation of personnel for accident localization and elimination in the initial stages is carried out only by the divisions of the Federal State Unitary Enterprise “Militarized Mine Rescue Unit” (FSUE “VGSCH”).

The mine rescue service in Russia traces its origins back to the 32nd Congress of Mine Industrialists in 1907, where the decision was made to establish rescue stations at the most dangerous mines and pits. By 1920, over 40 stations had been set up, staffed by engineers, technical workers, and miners working parttime for additional pay.

The professional state mine rescue service of Russia, with a centralized management structure, was officially established on July 6, 1922, following the adoption of the government resolution “On Mine Rescue Operations in the RSFSR”2. All mine rescue stations were brought under state control and tasked with rescuing people and mitigating accidents at all mining enterprises without exception.

In 1932, recognizing the extreme nature of mine rescue work in high-temperature, oxygen-deprived environments, and the need for strict command and execution of orders, the Council of Labour and Defence militarized the mine rescue units, placing them under the authority of the Department of Military Specialized Units and Air Defence of the People's Commissariat of Heavy Industry. This decision accelerated the development of mine rescue units in the country. Operational work became regulated by official charters, provisions, and instructions, with established ranks for personnel ranging from privates to senior officers. Uniforms and insignia were also introduced.

Until 2010, mine rescue services for mining operations were provided were provided by various militarized mine rescue services, including FGKU “VGSCH in Construction”, JSC “VGSCH”, and FSUE “Metallurgbezopasnost”, which all shared the same mission – saving lives and eliminating accidents during mining operations in coal, mining, and underground construction industries.

In 2010, by Presidential Decree No. 5543 of May 6, 2010, the oversight of militarized mine rescue units was transferred to the Ministry of Emergency Situations (EMERCOM) of Russia.

In 2011, FSUE “SPO Metallurgbezopasnost” was renamed FSUE “Militarized Mine Rescue Unit”, and all operational units of JSC “VGSCH” were incorporated into its structure.

At present, the Ministry of Emergency Situations of Russia includes five militarized mine rescue organizations: FSUE “VGSCH”, FAU “VGSCH in Construction”, FGKU “National Mine Rescue Centre”, FGKU “VGSCH LNR”, and FGKU “VGSCH DNR”. The total number of personnel in these organizations is 8,584.

Operational units of VGSCH EMERCOM are territorially distributed across 40 regions of the Russian Federation (Fig. 1) and include 26 militarized mine rescue detachments, consisting of 71 platoons, 103 mine rescue posts, and 25 mine rescue stations equipped with specialized equipment, tools, and materials.

Fig. 1. Deployment of units and composition of VGSCH forces within EMERCOM of Russia

VGSCH EMERCOM units provide coverage for 2,350 hazardous industrial facilities in the mining industry, including 168 coal mines, 143 underground mineral extraction sites, 28 underground construction facilities, 1,259 open-pit mining sites, 224 mineral processing and enrichment plants, and 528 other hazardous production sites.

The VGSCH forces of Russia's EMERCOM comprise 5,487 personnel and 978 units of equipment (specifically: FSUE “VGSCH” – 3,922 personnel and 756 units of equipment; FAU “VGSCH in Construction” – 216 personnel and 53 units of equipment; FGKU “National Mine Rescue Centre” – 66 personnel and 13 units of equipment; FGKU "VGSCH LNR" – 448 personnel and 71 units of equipment; FGKU “VGSCH DNR” – 835 personnel and 85 units of equipment). Of these, 1,364 rescuers and 276 units of equipment are on round-the-clock duty.

The management of VGSCH within the central apparatus of EMERCOM is assigned to the Rescue Units Department, which is responsible for overseeing the activities of VGSCH, coordinating with regional branches of EMERCOM, and developing a unified national policy for the development, training, and deployment of VGSCH.

A special role in the emergency protection system is given to Auxiliary Mine Rescue Teams (AMRT). To date, nearly 100,000 members of AMRT have been trained.

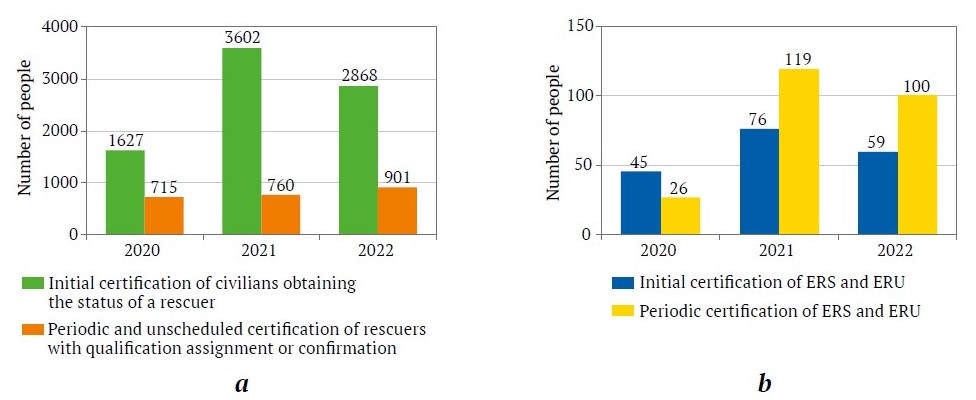

Each year, thousands of miners participate in both initial and refresher training (Fig. 2). The training follows a standardized and approved curriculum, conducted every three years. Additionally, every six months, members of the AMRT undergo team-based training in the use of isolating breathing apparatus.

Fig. 2. Certification statistics of AMRT members (a) and emergency rescue services (units) (ERS/ERU) (b)

To assess the necessity and effectiveness of the auxiliary mine rescue teams, research was conducted that included expert evaluations and tactical exercises at seven mines in Russia.

1 Handbook of training in mine rescue and recovery operations. Workplace Safety North (WSN). North Bay Ontario; 2021. 378 p.; Western Canada Mine Rescue Manual Ministry of Energy and Mines. Office of the Chief Inspector of Mines; 2016. 195 p.

2 Decree of the All-Russian Central Executive Committee and the Council of People’s Commissars “On Mine Rescue in the RSFSR”. URL: https://scgss.narod.ru/Postanovlenie.gif

3 Presidential Decree of the Russian Federation No. 554, dated May 6, 2010, “On the Improvement of the Unified State System for the Prevention and Mitigation of Emergency Situations”. URL: http://www.kremlin.ru/acts/bank/31043

Research on the effectiveness of AMRT actions

A survey was conducted among the command staff of VGSCH, with 334 respondents participating. Of these, 89% of professional rescuers believe that auxiliary mine rescue teams should be established at mining enterprises.

However, 82% of respondents feel that AMRT members are exposed to less life-threatening risk than professional mine rescuers. Additionally, only 5% reported that AMRT members had been injured during accident localization and mitigation efforts.

An interesting result emerged when respondents were asked if AMRT members had ever refused to participate in emergency rescue operations (ERO). Responses were almost evenly split: 53% said yes, while 47% said no. This brings the issue of motivation into focus. It is one thing to be a member of the AMRT, but another to enter a mine during an accident and risk one’s life and health.

The main challenges in preparing AMRT members, according to the mine rescue community, are insufficient physical training, low proficiency in operating mine rescue equipment, and difficulties with self-organization. Nearly unanimously (75%), respondents agreed that the number of training hours for AMRT members needs to be increased. Currently, AMRT training lasts 72 hours as part of their certification.

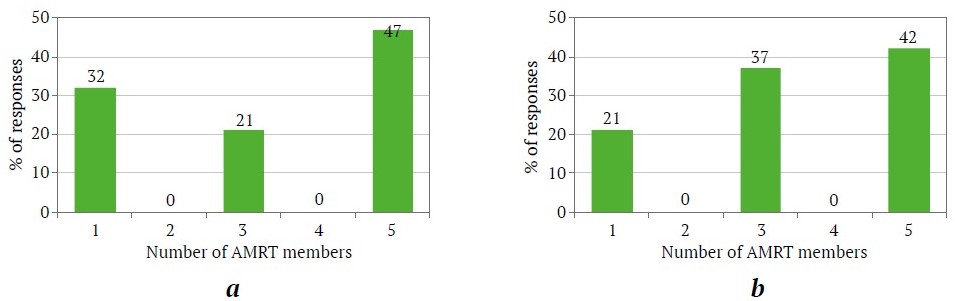

Questions about the necessary number of AMRT members required for tasks such as first aid or firefighting remain unanswered (Fig. 3). Consequently, many questions arise regarding the tactics used by AMRT members during rescue operations. At present, there is no officially approved tactical document specifically for AMRT. In the absence of such a document, AMRT members rely on the regulations followed by professional mine rescuers during emergency response operations.

Fig. 3. The required minimum number of AMRT members: а) for providing first aid to the injured, b) for firefighting

When asked, “What do AMRT members lack?” almost all respondents pointed to skills in working as part of a team.

It is crucial to understand how effective AMRT rescue operations truly are, especially considering the significantly different starting conditions they face compared to professional mine rescuers. For instance, an accident could occur at the end of a work shift, after AMRT members have already worked 6–8 hours at their regular jobs. Unlike professional mine rescuers, AMRT members do not have the same level of ingrained proficiency in using breathing apparatus, honed through repeated practice.

Assessment of AMRT readiness in coal mines

To objectively assess readiness, control-tactical exercises (CTE) were conducted at seven mines at the end of the work shift, focusing on fire scenarios.

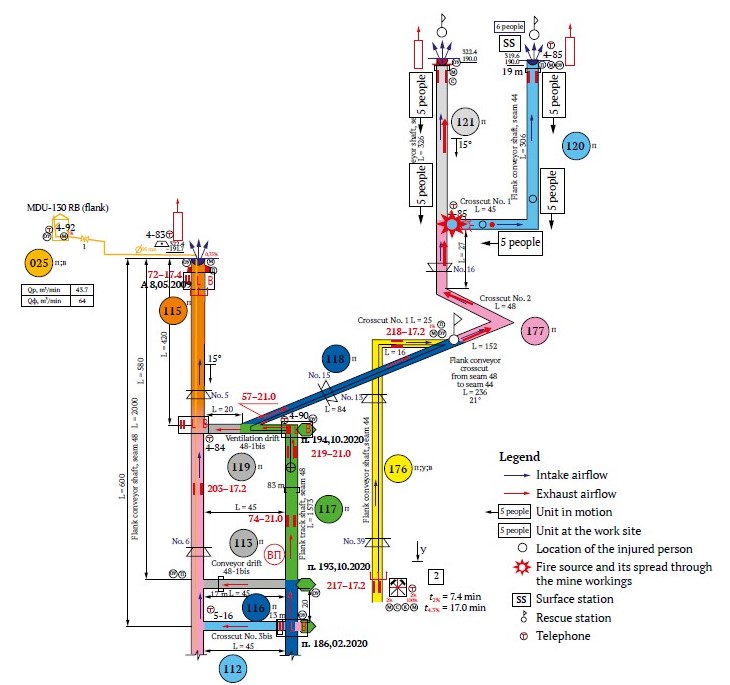

For example, at Mine “1” (Fig. 4), the accident location and type (fire) were determined, and the relevant fire protection measures were activated.

Fig. 4. Plan of the accident site. Accident location – Crosscut No. 1. Type of accident: “Fire”

All deficiencies made by AMRT members were carefully tracked, including critical ones that could lead to fatalities in a real emergency. For instance, at Mine “1”, the commander failed to inform the unit about the affected areas and potential accident spread routes. Additionally, an AMRT member did not check their helmet mask. When entering the high-temperature zone (HTZ), the AMRT unit did not use cooling elements or monitor the temperature in the HTZ, among other errors.

Theoretical knowledge was also evaluated. While passing theory during certification is one thing, doing so at the end of a shift without preparation is another. The average score was around three (on a five-point scale), with work experience not significantly affecting the results. Physical fitness was also assessed on-site, and nearly all members passed the required standards. Skills in first aid, task allocation, and preparation for mine descent were also evaluated, and an overall score was given.

Summarizing the results from all mines, critical deficiencies were identified at each site. At Mine “2”, the commander failed to properly brief the unit on safety protocols and miscalculated the time required to advance into the high-temperature zone (HTZ). At Mine “3”, the commander neglected to instruct the unit to secure themselves with ropes, failed to inform the team about the gas levels, and did not mention the need to disconnect from respirators when necessary. During movement through the mine and while inside the HTZ, both the commander and the team did not adhere to the correct practice of staying in the lower sections of the mine workings. At Mine “4”, the commander did not communicate the potential spread of the accident within the mine workings. Unit 1 proceeded to enter gas-filled areas directly at the entrance to the affected zone, where the air was being contaminated by the fire. At Mine “5”, the commander incorrectly calculated the oxygen supply needed to advance in an atmosphere unsuitable for breathing. At Mine “6”, the commander did not notify the unit about the impacted areas or the potential spread of the accident.

In real situations, these and other errors could result in the deaths of AMRT members and worsen the accident.

Conclusion

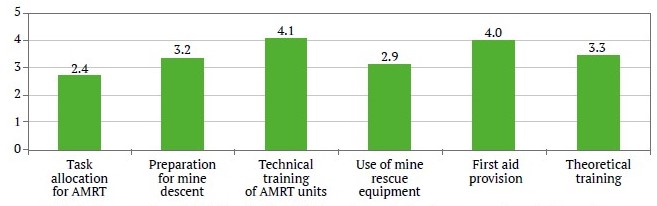

Critical deficiencies were noted at all mines. The overall performance results are summarized in the diagram (Fig. 5). The biggest issues were in task allocation and the use of rescue equipment, while tactical preparation and first aid procedures were relatively stronger. These areas will be the focus of future improvements.

Fig. 5. Average chart of deficiencies in AMRT member training from control-tactical exercises

It should be noted that some types of accidents [8] are more complex, making it difficult to quickly locate the accident site. In such cases, the risk of AMRT members making incorrect decisions is higher.

Table

Assessment of theoretical competence and physical fitness

No. | Year of birth | Current position | Position in AMRT at the mine | Education | Experience (years) | Test scores | Overall assessment of theoretical competence of AMRT members | Pull-up requirement (Yes/No) | Push-up requirement (Yes/No) |

| 1. | 1978 | Deputy chief engineer | AMRT Leader | Higher | 18 | 4 | 3.3 | Yes | Yes |

| 2. | 1978 | Mine foreman | Squad Leader AMRT No.1 | Technical | 15 | 3 | No | Yes | |

| 3. | 1987 | Miner | AMRT Member | Higher | 5 | 4 | Yes | Yes | |

| 4. | 1993 | Stope miner | AMRT Member | Secondary | 7 | 3 | Yes | Yes | |

| 5. | 1992 | Underground equipment operator | AMRT Member | Secondary | 4 | 3 | No | Yes | |

| 6. | 1983 | Stope miner | AMRT Member | Secondary | 15 | 3 | Yes | No | |

| 7. | 1995 | Deputy section head | Squad Leader AMRT No.2 | Secondary | 10 | 3 | Yes | Yes | |

| 8. | 1995 | Driller | AMRT Member | Secondary | 3 | 3 | Yes | Yes | |

| 9. | 1989 | Driller | AMRT Member | Technical | 9 | 3 | Yes | No | |

| 10. | 1995 | Miner | AMRT Member | Secondary | 4 | 3 | Yes | Yes | |

| 11. | 1983 | Stope miner | AMRT Member | Secondary | 12 | 4 | Yes | No |

Possible ways to improve safety and efficiency of AMRT operations:

- Boost motivation by significantly increasing the additional compensation – currently, the supplementary pay ranges from 3–10% of base salary; by offering government guarantees of support for AMRT members in the event of injury during rescue operations; and by ensuring support for their families in the case of death or injury.

- Increase the number of training hours for AMRT members, conduct unannounced inspections, and organize competitions across mining industry organizations.

- Develop rescue operation tactics that account for the number of AMRT members available at the accident site, potential issues with team cohesion, and the physical condition of miners at different points in their work shift.

Only by implementing this comprehensive set of measures can the safety and effectiveness of AMRT rescue operations be improved.

References

1. Petrov V. L., Puchkov L. A. The system of higher mining education in Russia. Eurasian Mining. 2017;(2):57–60. https://doi.org/10.17580/em.2017.02.14

2. Petrov V. L. Analytical review of the training system for mining engineers in Russia. Mining Science and Technology (Russia). 2022;7(3):240–259. https://doi.org/10.17073/2500-0632-2022-3-240-259

3. Kaledina N. O. Engineer training of mine rescue men. Gornyi Zhurnal. 2018;(5):86–89. (In Russ.) https://doi.org/10.17580/gzh.2018.05.14

4. Kobylkin S. S., Rudenko V. A. Training of miners in mine rescue. Ugol’. 2023;(11):30–42. (In Russ.) https://doi.org/10.18796/0041-5790-2023-11-30-42

5. Kolikov K. S., Grishin V. Yu., Ishkhineli O. G. Accidents and injuries at coal industry enterprises. Okhrana Truda i Sotsial’noye Strakhovaniye. 2020;(6):34–44. (In Russ.)

6. Kolikov K. S., Kaledina N. O., Kobylkin S. S. Mining Safety and Ecology Department: past, present and future. Gornyi Zhurnal. 2018;(3):21–28. (In Russ.) https://doi.org/10.17580/gzh.2018.03.04

7. Enright C., Ferriter R. L. Mine rescue manual. a comprehensive guide for mine rescue team members. Society for Mining, Metallurgy, and Exploration, Inc.; 2015. 196 p.

8. Kobylkin S. S., Kharisov A. R. Design features of coal mines ventilation using a room-and-pillar development system. Journal of Mining Institute. 2020;245;531–538. https://doi.org/10.31897/PMI.2020.5.4

About the Author

V. A. RudenkoRussian Federation

Vitaly A. Rudenko – First Deputy General Director

Moscow

Review

For citations:

Rudenko V.A. Assessment of readiness of auxiliary mine rescue teams in coal mines. Mining Science and Technology (Russia). 2024;9(3):243-249. https://doi.org/10.17073/2500-0632-2024-03-234

JATS XML